Thermoelectric power generation device implemented on driving vehicles

A technology for thermoelectric power generation and transportation, which is applied to generators/motors, electrical components, etc., can solve the problems of increased power consumption, high production and installation requirements, and complicated production and processing of exhaust pipes, and achieves high power generation efficiency and heat dissipation efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

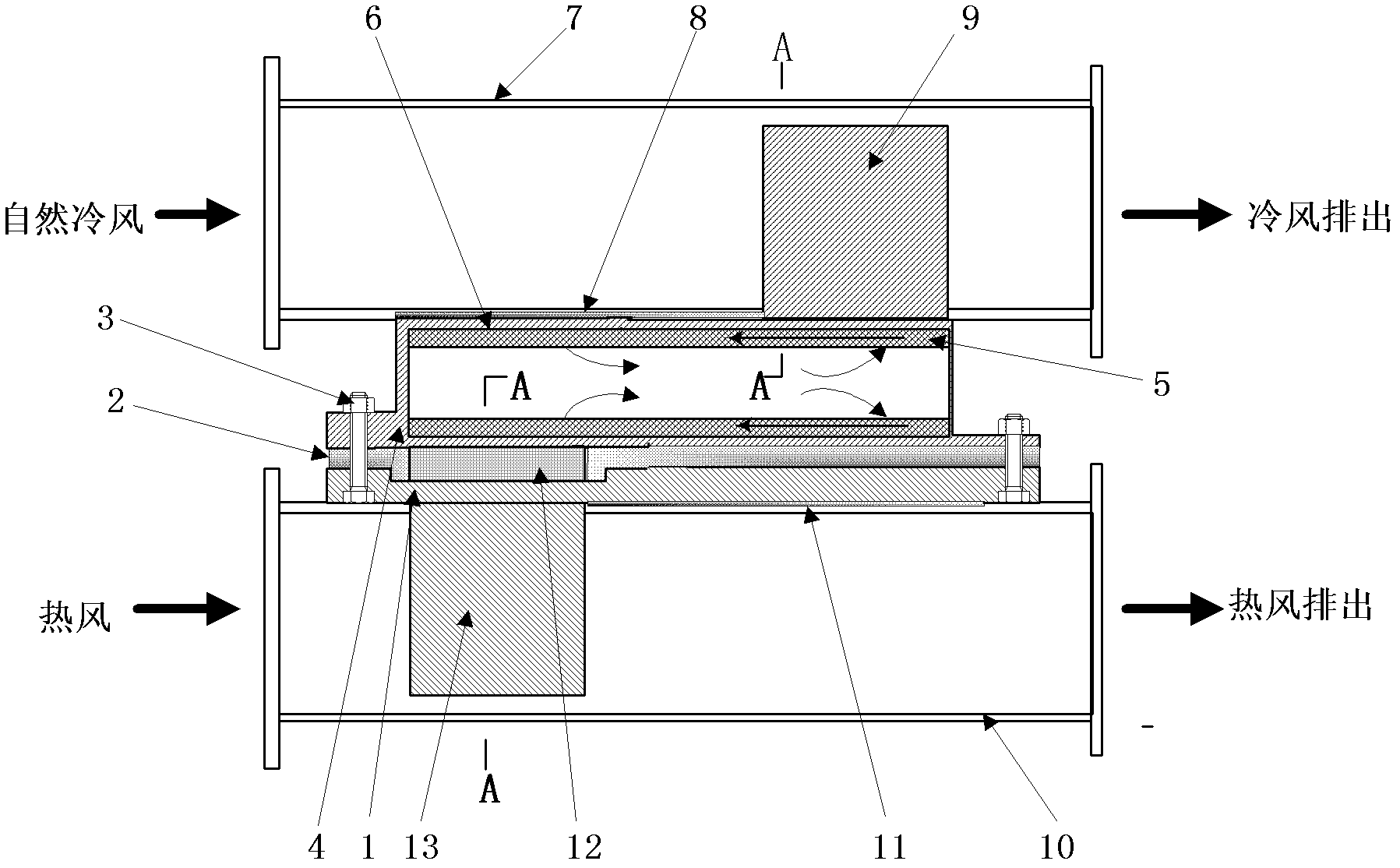

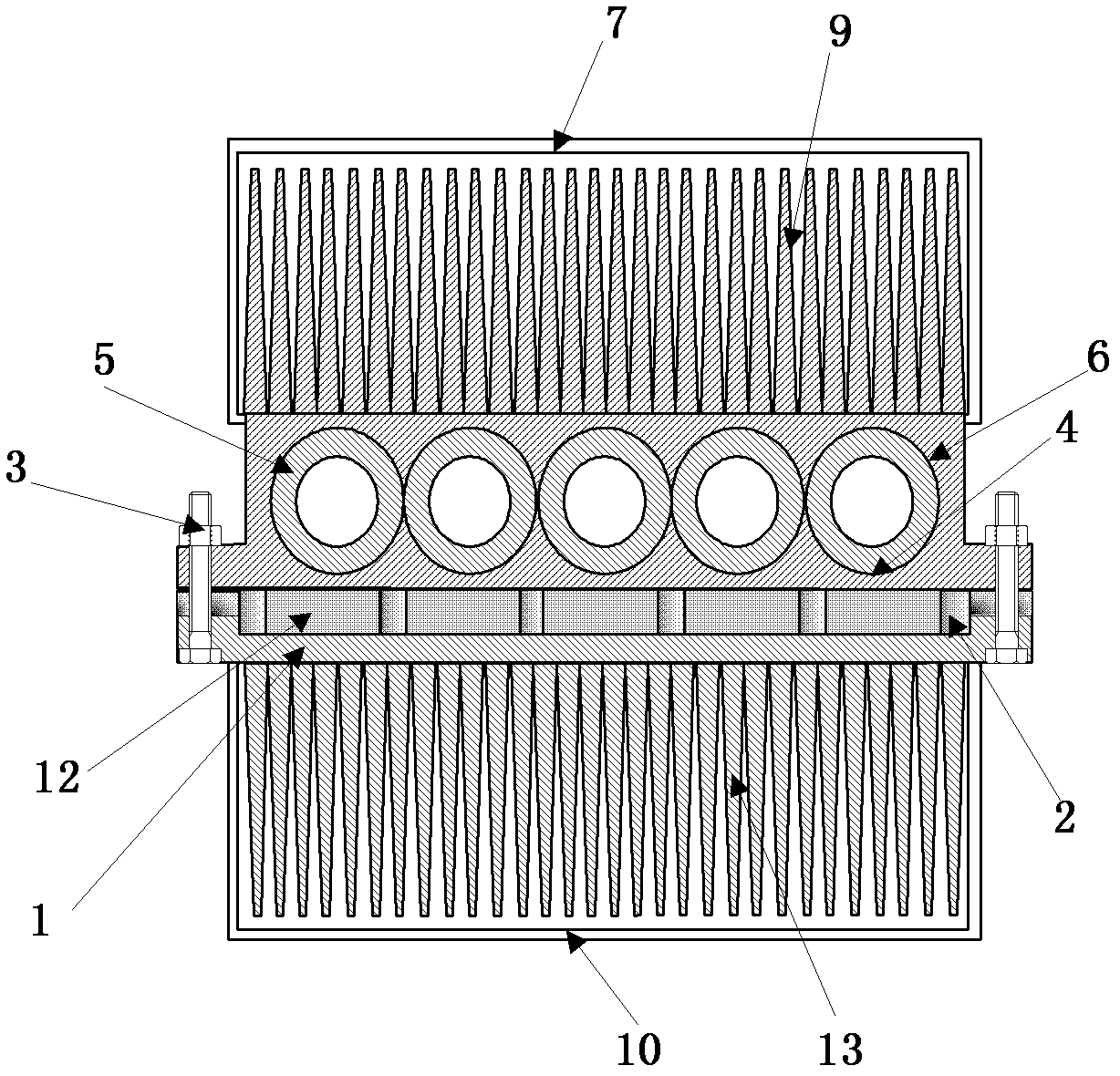

[0027] The thermoelectric power generation device implemented on the driving vehicle disclosed in this embodiment, its structure is as follows: figure 1 And attached figure 2As shown, the exhaust gas emitted by the vehicle engine is used for thermoelectric power generation. Its composition includes a device body, a thermoelectric power generation sheet assembly 12 installed on the device body, a heat pipe and a radiator. The device body is a split structure, one part is the heat collecting end 1 of the device body, and the other part is the heat dissipation end 4 of the device body. The thermoelectric power generation sheet assembly 12 is located between the heat collecting end and the heat dissipation end of the device body. It is opposite to the heat collecting end of the device body, and the low temperature end is opposite to the heat dissipation end of the device body. The thermoelectric power generation sheet assembly is fixed between the two parts of the device body th...

Embodiment 2

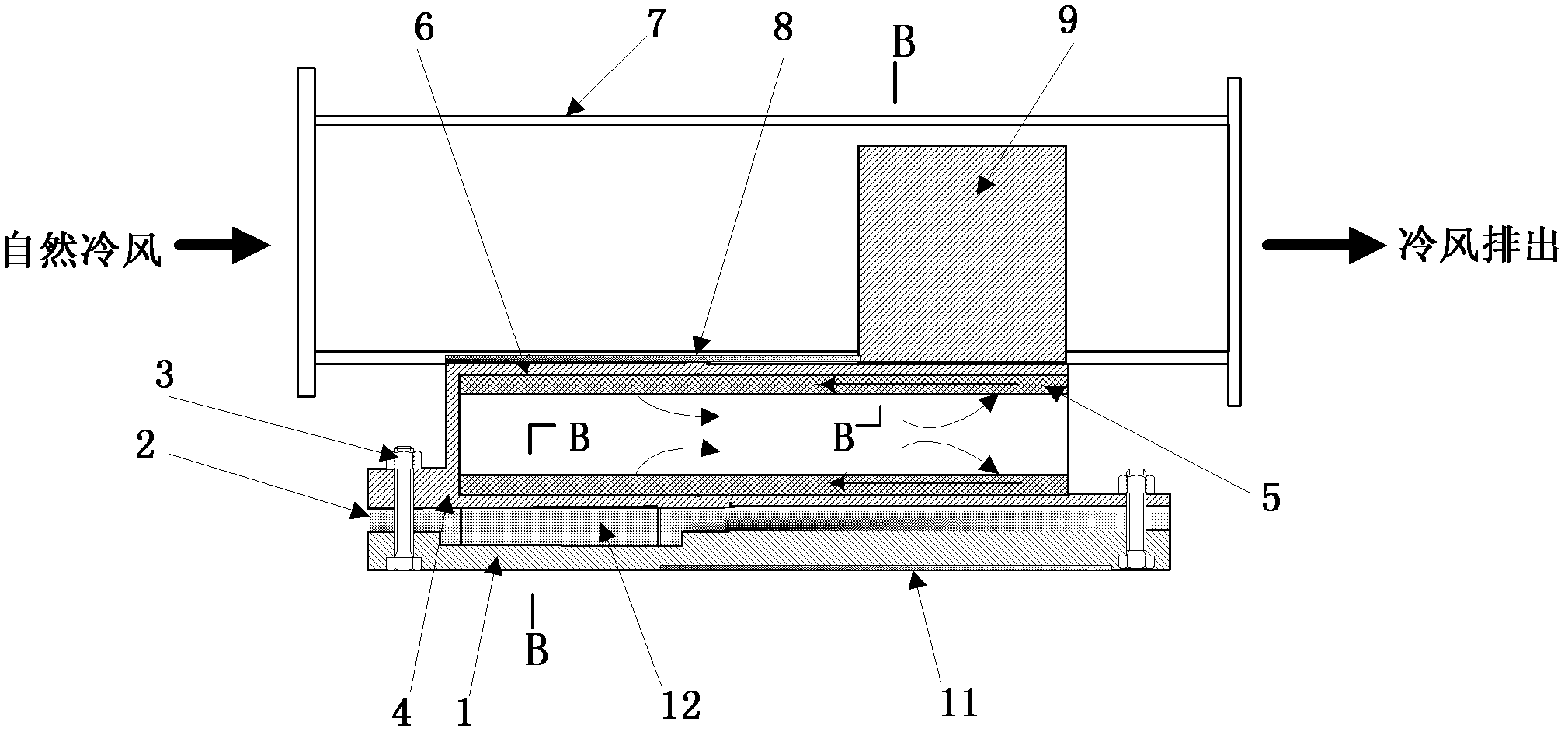

[0030] The thermoelectric power generation device implemented on the driving vehicle disclosed in this embodiment, its structure is as follows: image 3 And attached Figure 4 As shown, the heat dissipated by the engine body of the vehicle is used for thermoelectric power generation. The basic structure of this thermoelectric power generation device is the same as that of Embodiment 1, except that the heat collecting end of the device body is directly fixed on the engine body, and the heat collector part in Embodiment 1 is omitted.

Embodiment 3

[0032] The thermoelectric power generation device disclosed in this embodiment implemented on a moving vehicle uses the hot gas at a relatively high temperature in the engine compartment of the vehicle to perform thermoelectric power generation. The basic structure of this thermoelectric power generation device is substantially the same as that of Embodiment 1, except that the heat pipe and the radiator are different. The pipe body of the heat pipe is not a straight pipe, but a curved pipe. The cooling fins of the radiator are directly welded on the heat pipe condensation section Structures on the body wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com