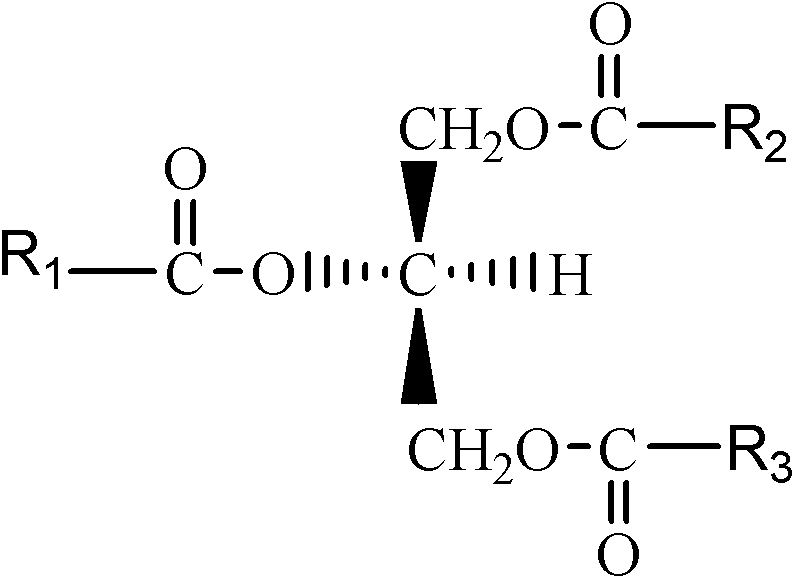

A kind of bio-based highly branched polyester and preparation method thereof

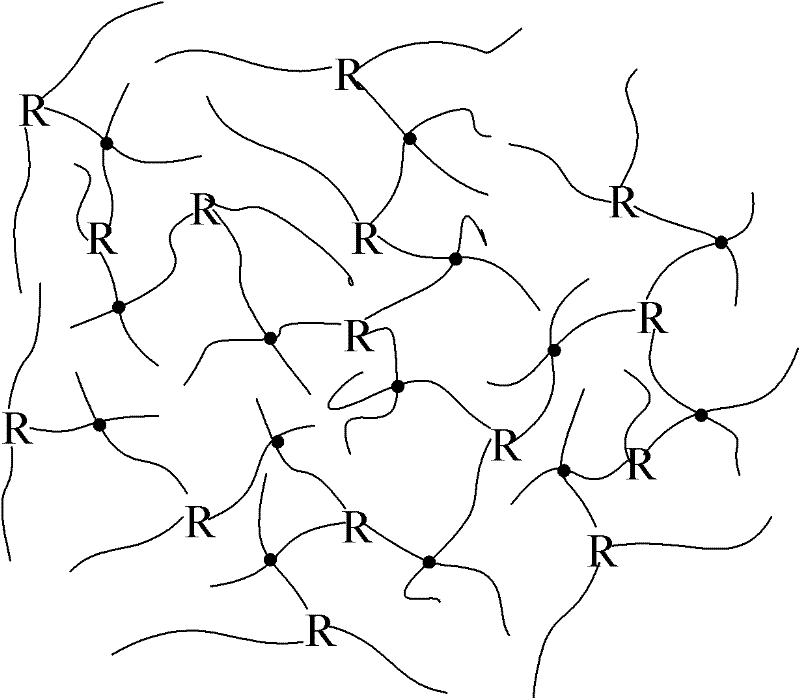

A highly branched, bio-based technology, applied in the field of polymer chemistry, can solve the problems of complex preparation methods and inability to further process, and achieve the effects of simple preparation methods, low glass transition temperature, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

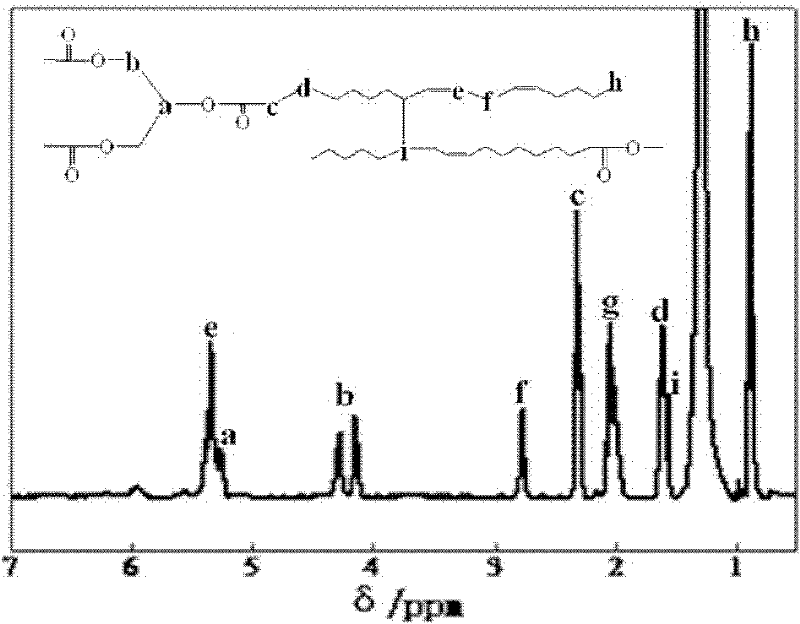

[0024] Embodiment 1: the preparation of rapeseed oil highly branched polyester

[0025] Add 100g of rapeseed oil and 10g of dicumyl peroxide (DCP) into a three-necked flask, heat to 160°C, and pass N 2 Protect, react for half an hour, and take it out. Dissolve 10 g of the prepared polymer in 80 ml of benzene, add 100 ml of ethanol dropwise to obtain a layered liquid, separate the liquids, collect the lower layer liquid to obtain the required hyperbranched polyester, dry it, and weigh 5.8 g of it. The number average molecular weight measured by GPC means is 30502 g / mol, and the polydispersity is 5.7. The glass transition temperature measured by differential scanning calorimetry is -72°C, and the decomposition temperature is 330°C.

[0026] Add 50 g of the rapeseed oil highly branched polyester prepared by the above method and 4 g of dicumyl peroxide into a 100 ml three-neck flask, heat to 80 ° C, stir for 10 min, quickly pour it into a mold, and place it on a flat vulcanizer ...

Embodiment 2

[0028] Embodiment 2: the preparation of soybean oil hyperbranched polyester

[0029] Add 100g of soybean oil and 15g of DCP into a three-necked flask, heat to 160°C, pass N 2 Protect, react for half an hour, and take it out. Dissolve 10 g of the prepared polymer in 60 ml of benzene, add 50 ml of ethanol dropwise to obtain a layered liquid, separate the liquids, collect the lower layer liquid to obtain the required hyperbranched polyester, and dry it to obtain a mass of 6.2 g. The number average molecular weight measured by GPC means is 50258g / mol, and the polydispersity is 5.9. The glass transition temperature measured by differential scanning calorimetry is -72°C, and the decomposition temperature is 345°C.

[0030] Add 50 g of the rapeseed oil highly branched polyester prepared by the above method and 4 g of dicumyl peroxide into a 100 ml three-neck flask, heat to 80 ° C, stir for 10 min, quickly pour it into a mold, and place it on a flat vulcanizer Perform vulcanization a...

Embodiment 3

[0031] Embodiment 3: the preparation of corn oil highly branched polyester

[0032] Add 100g of corn oil and 15g of DCP into the three-necked flask, heat to 160°C, pass N 2 Protect, react for half an hour, and take it out. 10 g of the prepared polymer was dissolved in 50 ml of benzene, and 90 ml of ethanol was added dropwise to obtain a layered liquid, which was separated, and the lower liquid was collected to obtain the required hyperbranched polyester, dried, and its mass was weighed to be 5.7 g. The number average molecular weight measured by GPC means is 45862 g / mol, and the polydispersity is 6.2. The glass transition temperature measured by differential scanning calorimetry is -68°C, and the decomposition temperature is 296°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com