Optical Frequency Precisely Tunable Lasers

A technology for tuning lasers and optical frequencies, applied in the field of optoelectronics, can solve the problems of wide filtering bandwidth, difficult to realize, low tuning accuracy and low output bandwidth, meet the requirements of reducing filtering bandwidth, easy installation and production, and meet the requirements of reliable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

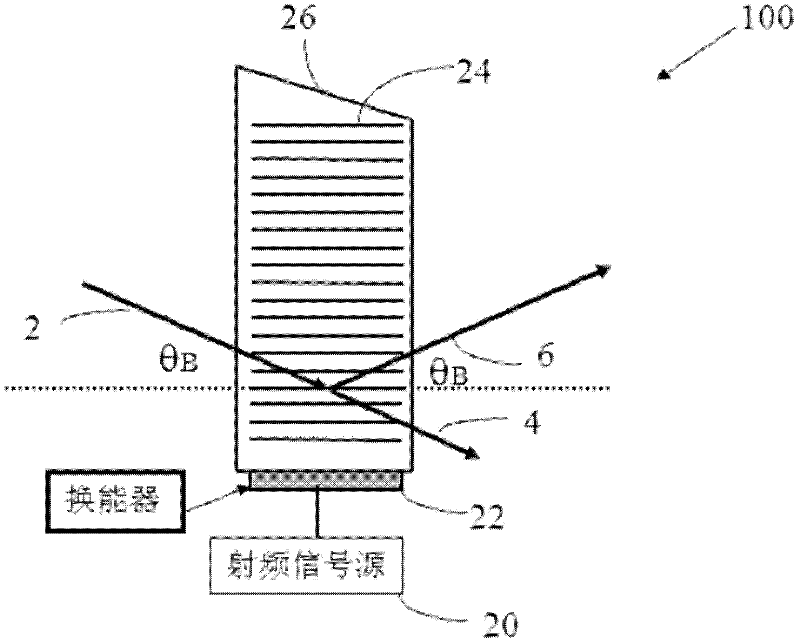

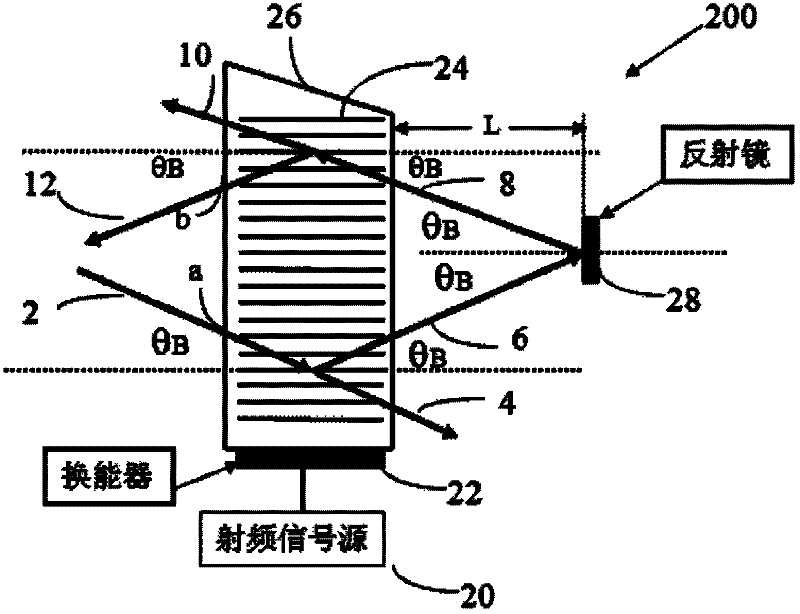

[0040] figure 1 A general tunable acousto-optic filter 100 is shown. The tunable acousto-optic filter 100 includes a transducer 22, a radio frequency signal source 20, and an acousto-optic crystal 26. The transducer 20 is installed on the acousto-optic crystal, and the incident light beam 2 is incident on the acousto-optic crystal 26 at a Bragg angle to generate zero First-order diffracted beam 4 and first-order diffracted beam 6.

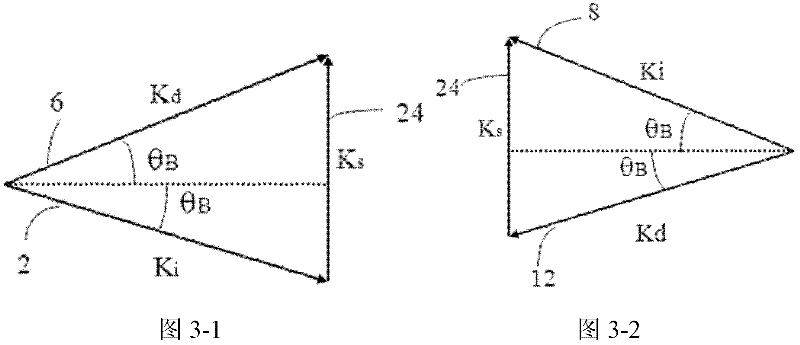

[0041] The working principle of acousto-optic filters is based on a phenomenon called Bragg diffraction. Bragg diffraction involves the interaction process of photons (quanta of light energy) and phonons (quanta of sound energy). During this interaction, both energy and momentum are conserved. Momentum Conservation Requirement in is the momentum of the diffracted photon, is the momentum of the incident pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com