Gallium nitride based semiconductor laser epitaxial structure and preparation method thereof

A gallium nitride-based, epitaxial structure technology, applied in the optical waveguide semiconductor structure and other directions, can solve the problems of difficult to achieve high vertical conductivity, high sub-band hole quality, etc., to improve radiation compliance efficiency, enhance electron The effect of blocking and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

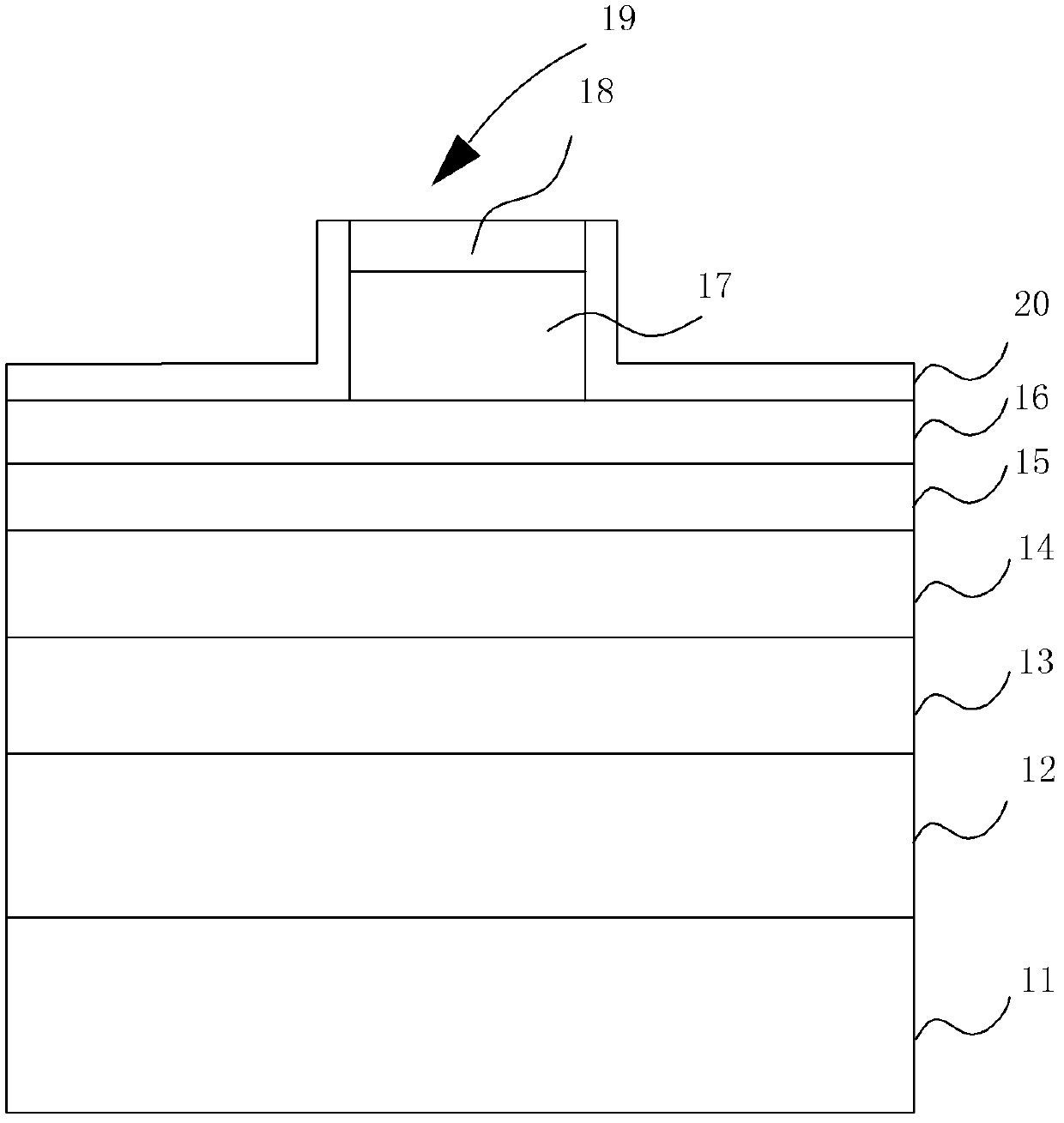

[0047] Such as figure 1 As shown, the GaN-based semiconductor laser epitaxial structure provided by the embodiment of the present invention includes:

[0048] The first layer is a gallium nitride substrate 11; wherein, the thickness of the gallium nitride substrate 11 is 300 μm, and Si is used as a donor impurity to form an n-type substrate, and its resistivity is about 0.001 Ωcm.

[0049] The second layer is an n-type optical confinement layer 12; this layer is a periodic AlGaN / GaN material with a superlattice structure, wherein the thickness of the n-type optical confinement layer 12 is 2 μm, Si is used as a donor impurity, and the Al composition is 4 %.

[0050] The third layer is the n-type InGaN lower optical waveguide layer 13; wherein, the thickness of the n-type InGaN lower optical waveguide layer 13 is 150nm, the composition of In is 4%, Si is used as the donor impurity, and its doping concentration is 1×10 17 cm -3 .

[0051] The fourth layer is the multi-quantum...

Embodiment 2

[0064] Such as figure 1 As shown, the GaN-based semiconductor laser epitaxial structure provided by the embodiment of the present invention includes:

[0065] The first layer is a SiC substrate 11; wherein, the thickness of the SiC substrate 11 is 300 μm, and Si is used as a donor impurity to form an n-type substrate, and its resistivity is about 0.001Ωcm.

[0066] The second layer is an n-type optical confinement layer 12; this layer is a periodic superlattice structure AlGaN / GaN material; wherein, the thickness of the n-type optical confinement layer 12 is 2 μm, Si is used as a donor impurity, and the Al composition is 4 %.

[0067] The third layer is the n-type GaN lower optical waveguide layer 13; wherein, the thickness of the n-type GaN lower optical waveguide layer 13 is 150nm, Si is used as the donor impurity, and its doping concentration is 1×10 17 cm -3 .

[0068] The fourth layer is the multi-quantum well InGaN / GaN active region 14; the thickness of the well is 3...

Embodiment 3

[0081] Such as figure 1 As shown, the GaN-based semiconductor laser epitaxial structure provided by the embodiment of the present invention includes:

[0082] The first layer is a SiC substrate 11; wherein, the thickness of the SiC substrate 11 is 300 μm, and Si is used as a donor impurity to form an n-type substrate, and its resistivity is about 0.001Ωcm.

[0083] The second layer is an n-type optical confinement layer 12; this layer is a periodic superlattice structure AlGaN / GaN material; wherein, the thickness of the n-type optical confinement layer 12 is 2 μm, Si is used as a donor impurity, and the Al composition is 4 %.

[0084] The third layer is the n-type InGaN lower optical waveguide layer 13; wherein, the thickness of the n-type InGaN lower optical waveguide layer 13 is 150nm, the composition of In is 8%, Si is used as the donor impurity, and its doping concentration is 1×10 17 cm -3 .

[0085] The fourth layer is the multi-quantum well InGaN / GaN active region 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com