Hydroxyapatite-based biological composite scaffold and tissue engineered bone

A hydroxyapatite and composite scaffold technology, which is applied in medical science, prosthesis, etc., can solve the problem that the porosity and pore size distribution of composite materials cannot be controlled, the composite materials cannot be directly used for bone tissue repair, and the viscosity of hydroxymethyl chitosan It is easy to control the degradation rate and pore size distribution, the distribution is ideal, and the mechanical properties are good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Preparation of hydroxyapatite-based biocomposite scaffold

[0031] Proceed as follows:

[0032] (1) remove the cocoons of silkworm cocoons, clean them, place them in 0.02mol / L sodium carbonate solution and boil them for 30 minutes according to the bath ratio of 10:1, and then wash them with deionized water to remove sericin, which has sensitization reactions to human tissues, get silk fibroin

[0033] (2) According to HA:SF:CS=8:1:1 in the final product, weigh the above degummed silk fibroin and dissolve it in calcium chloride-ethanol-water ternary solution, stir at 80°C for 30min, until completely Dissolve to obtain silk fibroin solution, which is placed in a three-necked flask for subsequent use; wherein, in the ternary solution, the molar ratio of calcium chloride: ethanol: water is 1: 2: 8;

[0034] (3) Taking calcium chloride as the calcium source, according to the Ca / P molar ratio is 1.67 configuration concentration is the diammonium hydrogen phosphate...

Embodiment 2

[0041] Example 2 Preparation of hydroxyapatite-based biocomposite scaffold

[0042] Example 1 was repeated with the HA:SF:CS ratio changed to 7:2:1.

Embodiment 3

[0043] Example 3 Preparation of hydroxyapatite-based biocomposite scaffold

[0044] Repeat Example 1, wherein (hydroxyapatite+silk fibroin+chitosan): the mass ratio of sodium chloride is changed to 1: 1.5.

[0045] The obtained hydroxyapatite / silk fibroin-chitosan composite scaffold of above-mentioned three embodiments carries out following detection:

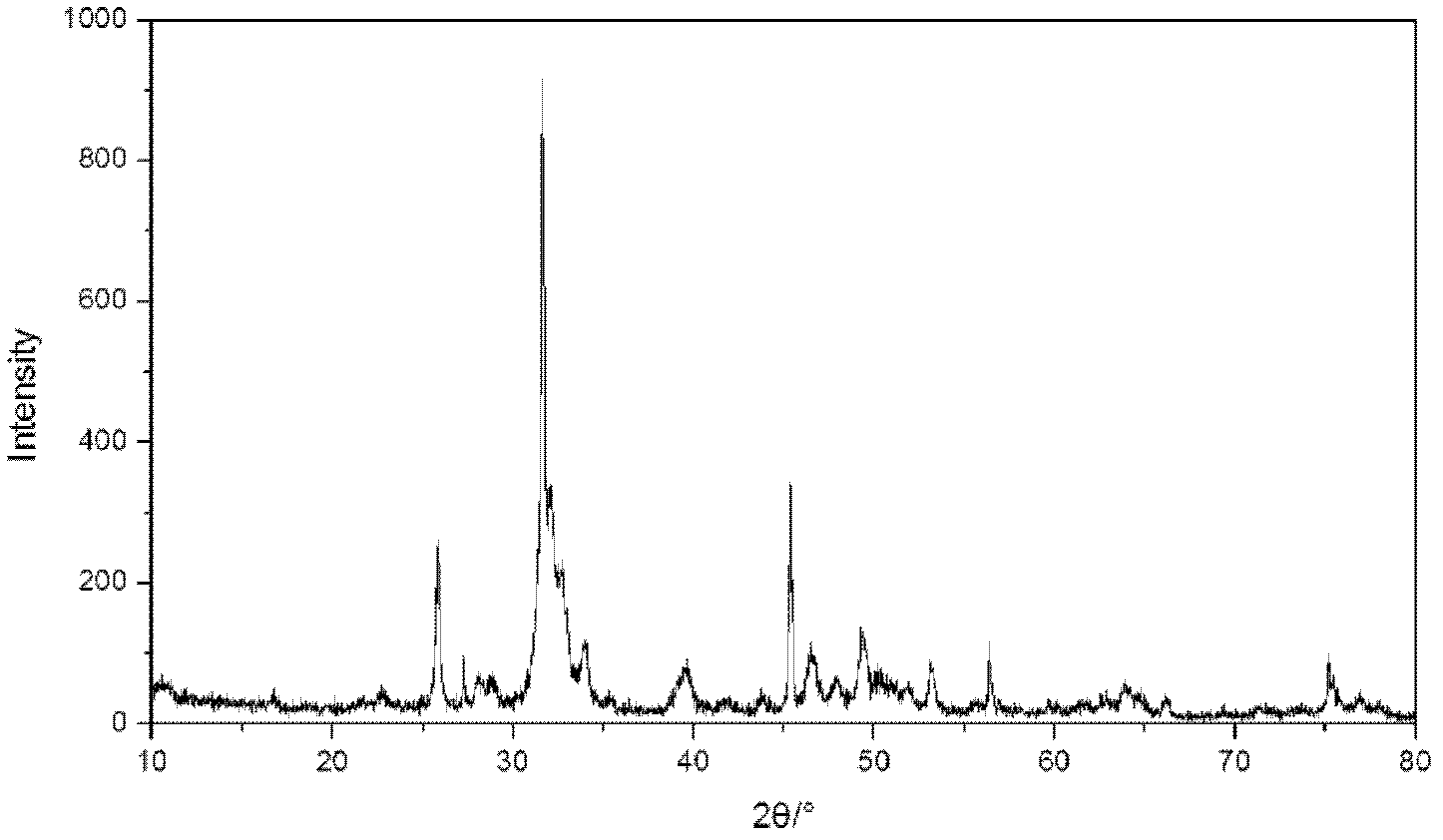

[0046] XRD and FT-IR detection confirmed that the composite scaffold is composed of three phases of hydroxyapatite, silk fibroin and chitosan, such as figure 1 shown;

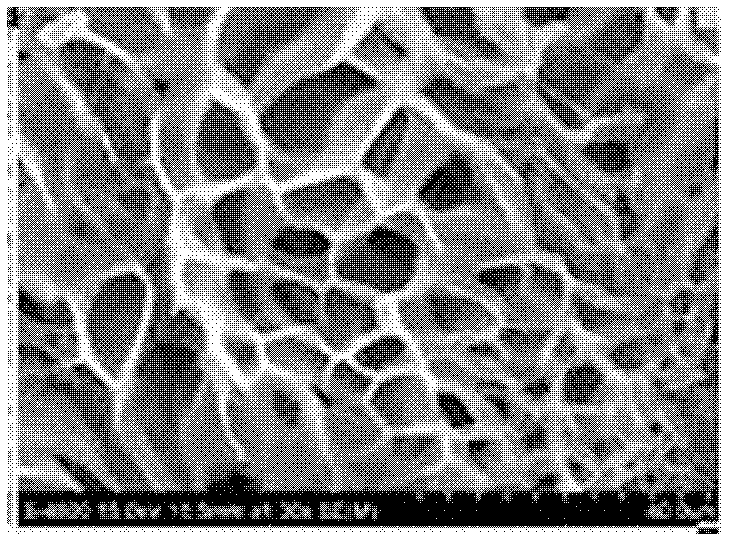

[0047] The analysis by JEM-100Cx II SEM shows that the mesopores in the composite scaffold are connected with each other, the porosity exceeds 70%, and the average pore diameter is between 150 and 200 μm ( figure 2 );

[0048] Tested by Shenzhen Sansi universal material testing machine: the compressive strength of composite scaffolds exceeds 150MPa, which meets the requirements of bone scaffold composite materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com