Polysaccharide compounded quick self-drying raw lacquer and preparation method thereof

A composite polysaccharide and raw lacquer technology, applied in the field of coatings, can solve the problems of no literature reports and unclear effects, etc., achieve good application prospects and market promotion value, convenient operation, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

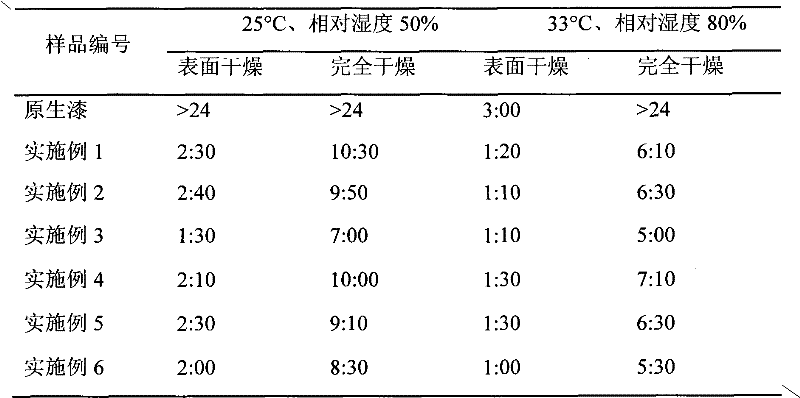

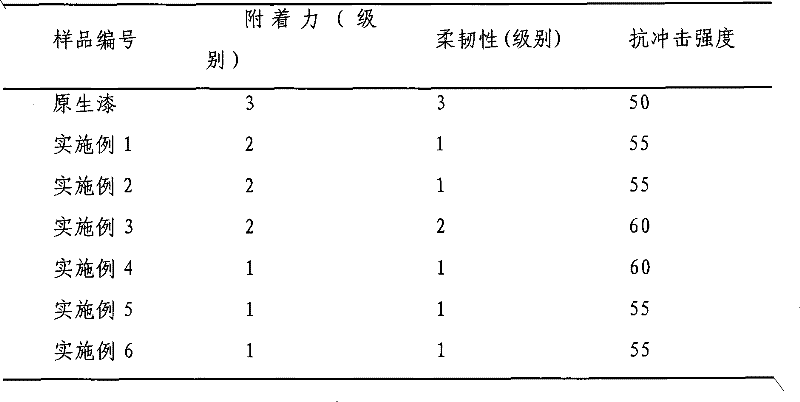

Examples

Embodiment 1

[0012] Example 1: Add 1% (w / v) carboxymethyl chitin to the lacquer emulsion at a ratio of 1% by mass, stir for 5 minutes, then add water-soluble lacquer polysaccharide powder at a ratio of 5% by mass, and stir for 35 minutes , Homogenized by a homogenizer for 30 minutes to prepare the raw lacquer of the complex polysaccharide.

Embodiment 2

[0013] Embodiment 2: in the chitosan acetic acid solution of 50ml 2% (w / v), drip the silica sol 10ml of 2% (w / w) with the speed of 0.1ml / s, stir 3h at 50 ℃, obtain silica sol - Chitosan solution.

[0014] The obtained silica sol-chitosan solution was added into the raw lacquer emulsion at a ratio of 5% by mass, stirred for 20 minutes, and ball milled for 1 hour to prepare the raw lacquer of the complex polysaccharide.

Embodiment 3

[0015] Embodiment 3: Take 100g of the original lacquer emulsion in a 500ml three-necked flask, and mechanically stir with the open mouth in a water bath at 40°C until the moisture content in the paint solution is 3% to 5%, to obtain the water-removing raw lacquer.

[0016] Add 2% (w / v) sulfoethylcellulose aqueous solution to the water-removing raw lacquer at a mass percentage of 5%, stir for 20 minutes, and then use a homogenizer to homogenize for 1 hour to obtain a complex polysaccharide raw lacquer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com