Method for preparing diamond

A diamond and equipment technology, applied in the field of diamond preparation with atomic layer deposition equipment, can solve the problems of high impurity amount and low dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present embodiment provides a kind of preparation method of diamond, specifically comprises the following steps:

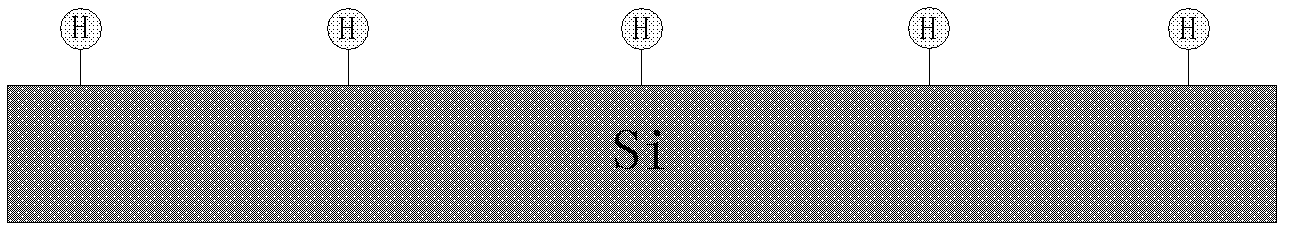

[0030] Step 101, placing the silicon (111) substrate cleaned by the standard solution in the reaction chamber of the atomic layer deposition equipment; wherein, the standard solution refers to: No. 1 solution, concentrated sulfuric acid: hydrogen peroxide = 4:1; No. 2 solution, ammonia water :Purified water:hydrogen peroxide=1:5:1; No. 3 solution, hydrochloric acid:hydrogen peroxide:purified water=1:1:6;

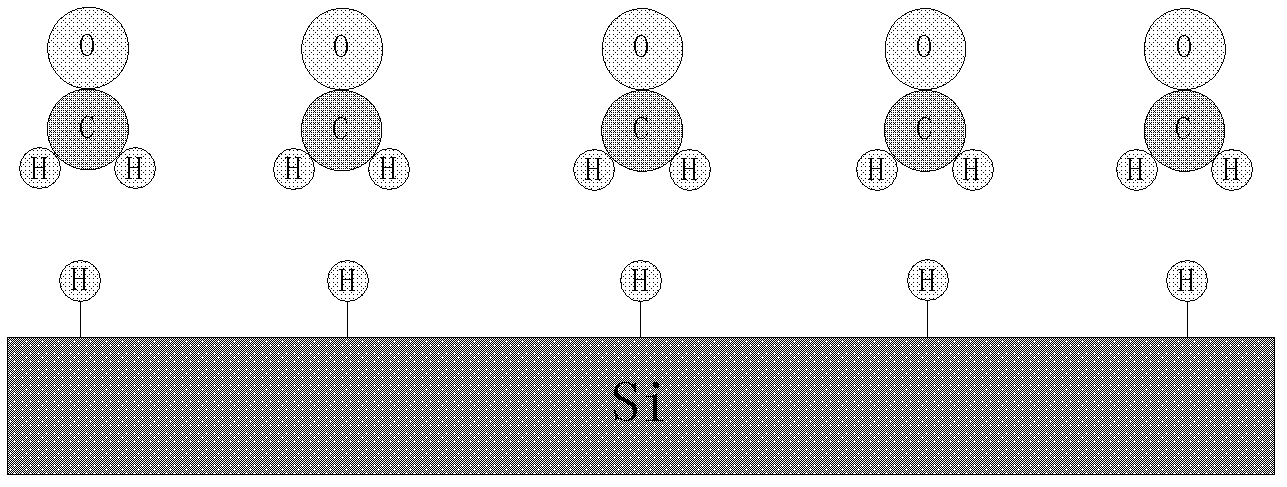

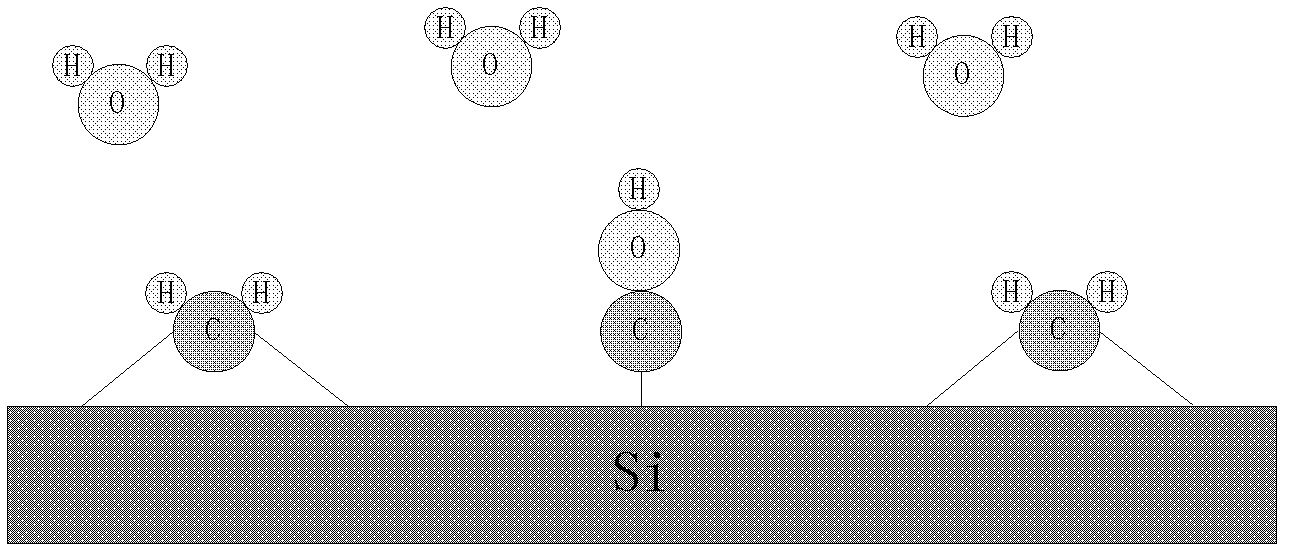

[0031] Step 102, using hydrogen as a carrier gas, transporting formaldehyde into the reaction chamber of the atomic layer deposition device; wherein the flow rate of hydrogen is 20 sccm-100 sccm. The flow rate of formaldehyde is 1sccm-10sccm, the volume ratio of hydrogen to formaldehyde is 40:1-20:1; hydrogen acts as carrier gas and activator in this step;

[0032] Step 103, plasma discharge is performed in the reaction chamber of the atomic layer de...

Embodiment 2

[0036] The present embodiment provides a kind of preparation method of diamond, specifically comprises the following steps:

[0037] Step 101, placing the silicon (111) substrate cleaned with the standard solution in the reaction chamber of the atomic layer deposition equipment;

[0038] Step 102, using hydrogen as a carrier gas, transporting methane into the reaction chamber of the atomic layer deposition device; wherein the flow rate of hydrogen is 5 sccm-50 sccm. The flow rate of methane is 10sccm-100sccm, and the volume ratio of hydrogen to methane is 40:1-20:1; hydrogen acts as carrier gas and activator in this step;

[0039] Step 103, plasma discharge is performed in the reaction chamber of the atomic layer deposition equipment, and the discharge power is controlled between 20W-150W. On the one hand, in order to control the decomposition amount of the precursor, and on the other hand, in order to control the ratio of the decomposed carbon and hydrogen atoms, so that The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com