Aluminum film-containing etching solution for liquid crystal display screen

A technology of etching solution and non-ionic surface, which is applied in the field of etching solution, can solve the problems of rough surface of metal film, lower product yield, poor use effect, etc., and achieve the effect of flat and smooth surface and inhibition of deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

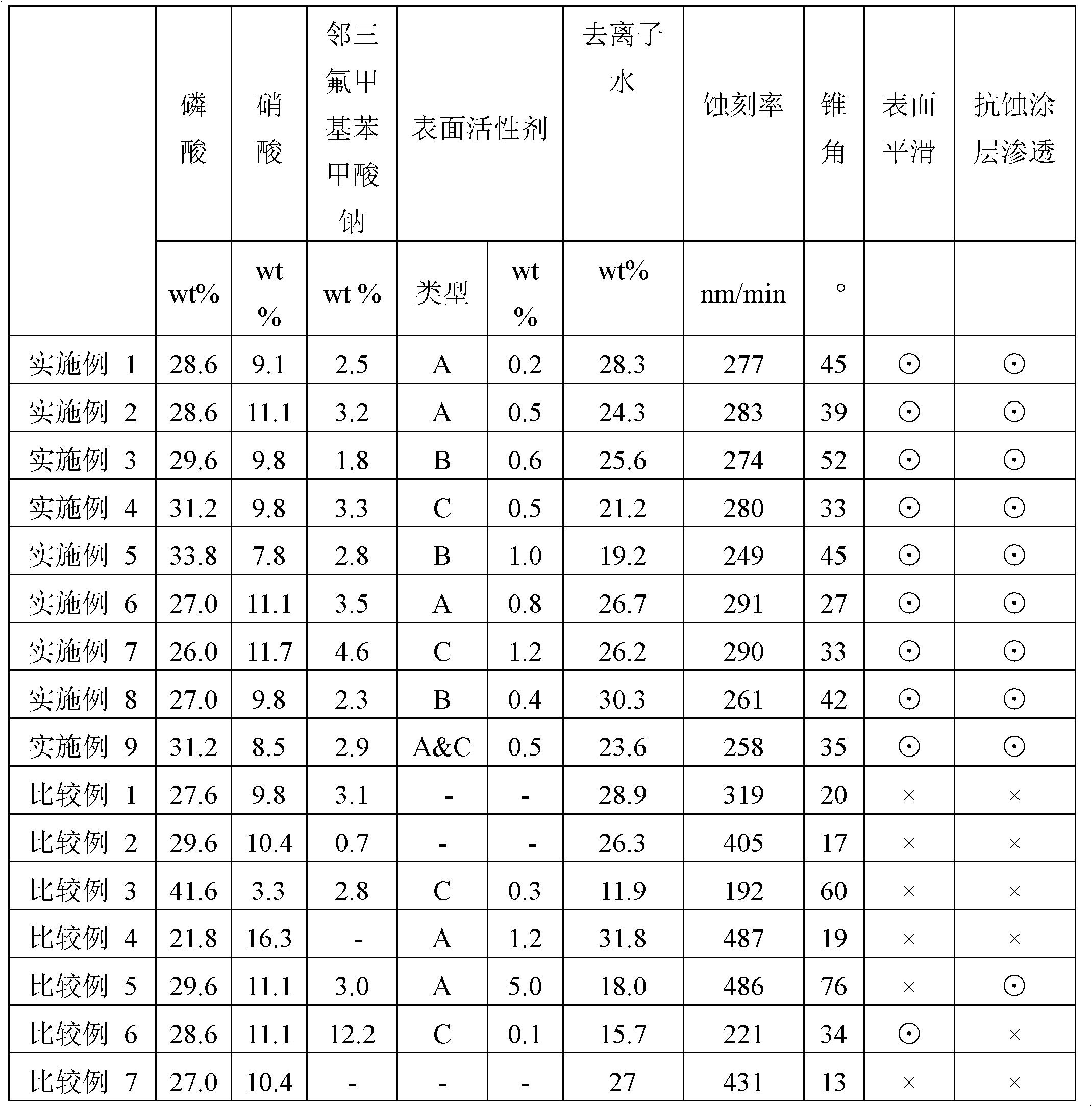

[0033] 55 parts by weight of phosphoric acid aqueous solution (equivalent to 28.6 parts by weight of pure phosphoric acid) with a mass percent concentration of 52%, 14 parts by weight of an aqueous solution of nitric acid (equivalent to 9.1 parts by weight of pure nitric acid) with a mass percent concentration of 65%, o-trifluoroform 2.5 parts by weight of sodium benzoate, 0.2 parts by weight of Span class nonionic surfactant sorbitan monolaurate (trade name Span 20) and 28.3 parts by weight of deionized water were mixed evenly, and then mixed with a 0.2 μm aperture The filter screen is filtered to obtain the etching solution containing aluminum film provided by the present invention.

[0034] Following exactly the same steps as above, only the above-mentioned raw materials were replaced as shown in Table 1, to obtain the aluminum-containing film etching solutions provided in Examples 2-9 and Comparative Examples 1-7.

[0035] Carry out the etching rate measurement of aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com