Preparation method of transmission electron microscope film sample through rapidly solidifying aluminum alloy powder

A technology for transmission electron microscopy and sample preparation, applied in the preparation of test samples, electrolytic coatings, coatings, etc., can solve the problems of poor bonding between Al-Fe-X alloy powder and nickel matrix, high cost, and complicated procedures, and achieve Reduce the preparation cost, solve the effect of poor bonding and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] Specific implementation mode 1: This implementation mode is a method for preparing a transmission electron microscope thin film sample of a rapidly solidified aluminum alloy powder, which is specifically completed according to the following steps:

[0014] 1. Configure the electroplating solution: the electroplating solution is made of NiSO 4 、H 3 BO 3 、Na 2 SO 4 , NaCl, MgSO 4 and H 2 Prepared from O, NiSO in the plating solution 4 The mass-volume concentration is 160-240g / L, H 3 BO 3 The mass-volume concentration is 28~35g / L, Na 2 SO 4 The mass-volume concentration of NaCl is 22-26g / L, the mass-volume concentration of NaCl is 14-18g / L, MgSO 4 The mass-volume concentration is 26 ~ 35g / L; 2. Connecting device: put the electroplating solution prepared in step 1 in a glass container, then put it into an acid and alkali resistant magnetic stirrer rotor, and place it on a magnetic heating stirrer , and finally immerse the electroplating plate connected to the DC ...

specific Embodiment approach 2

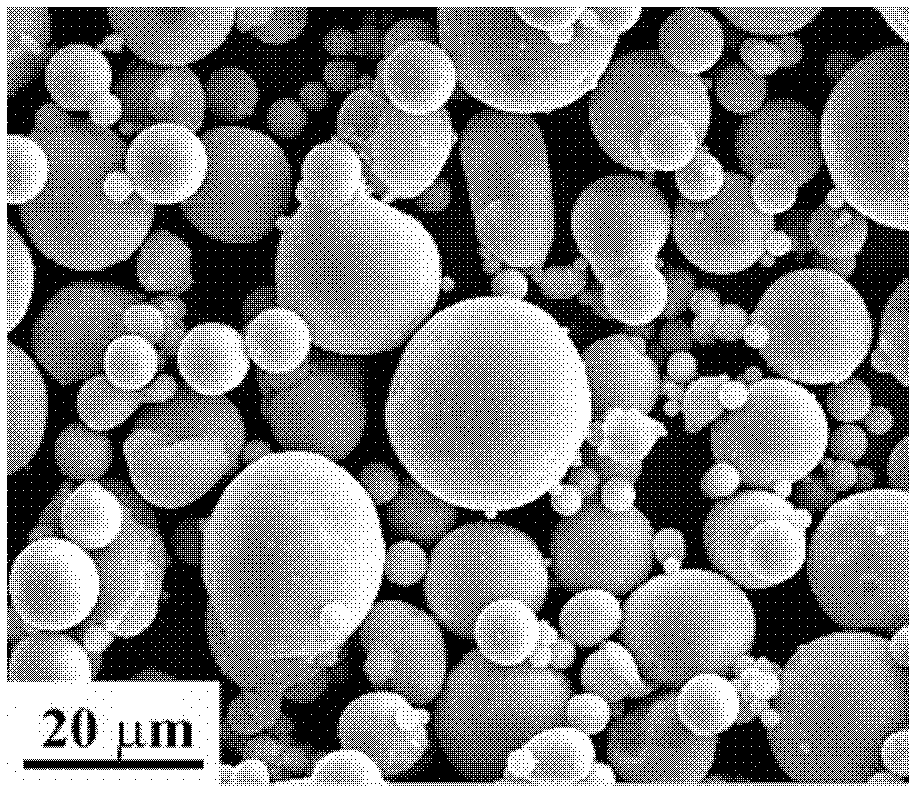

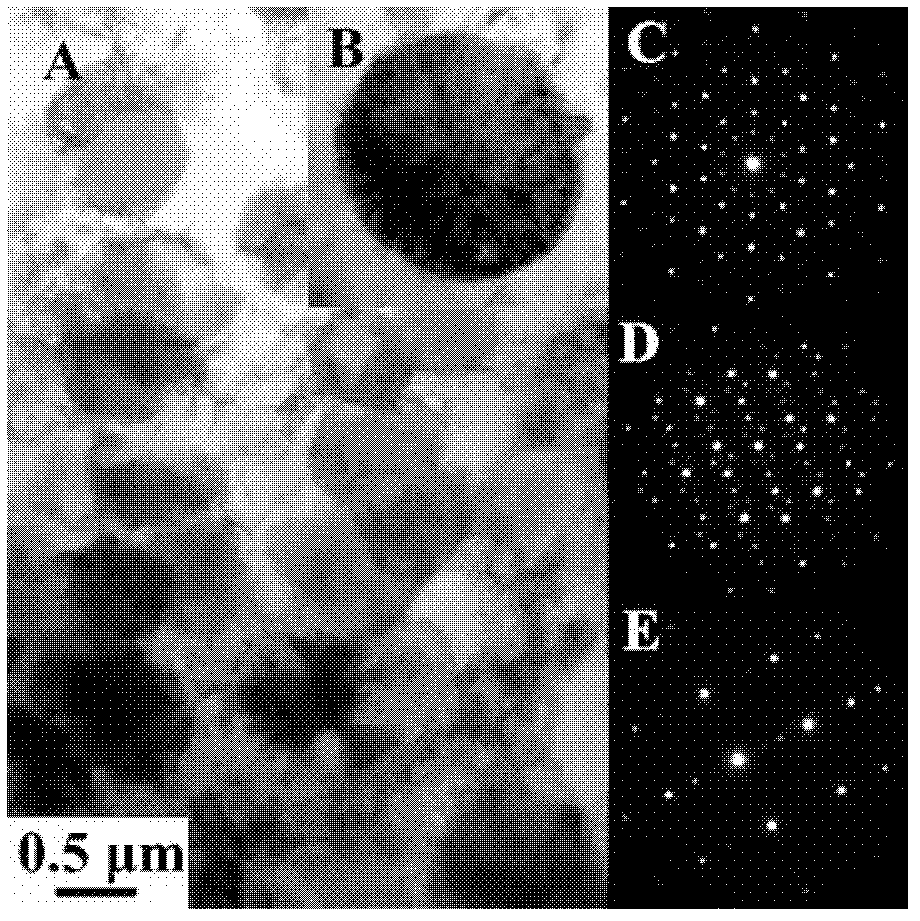

[0027] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the Al-Fe-X alloy powder described in step 3 is prepared by gas atomization method with a particle size of 1-40 μm alloy powder. - The atomic percentage of Al in the Fe-X alloy powder is 90-96%, the atomic percentage of Fe is 1-5%, and the atomic percentage of X is 1-7%, wherein the X is a transition One of group elements and rare earth elements or a combination of the two at an atomic percentage of 1:1. Others are the same as in the first embodiment.

specific Embodiment approach 3

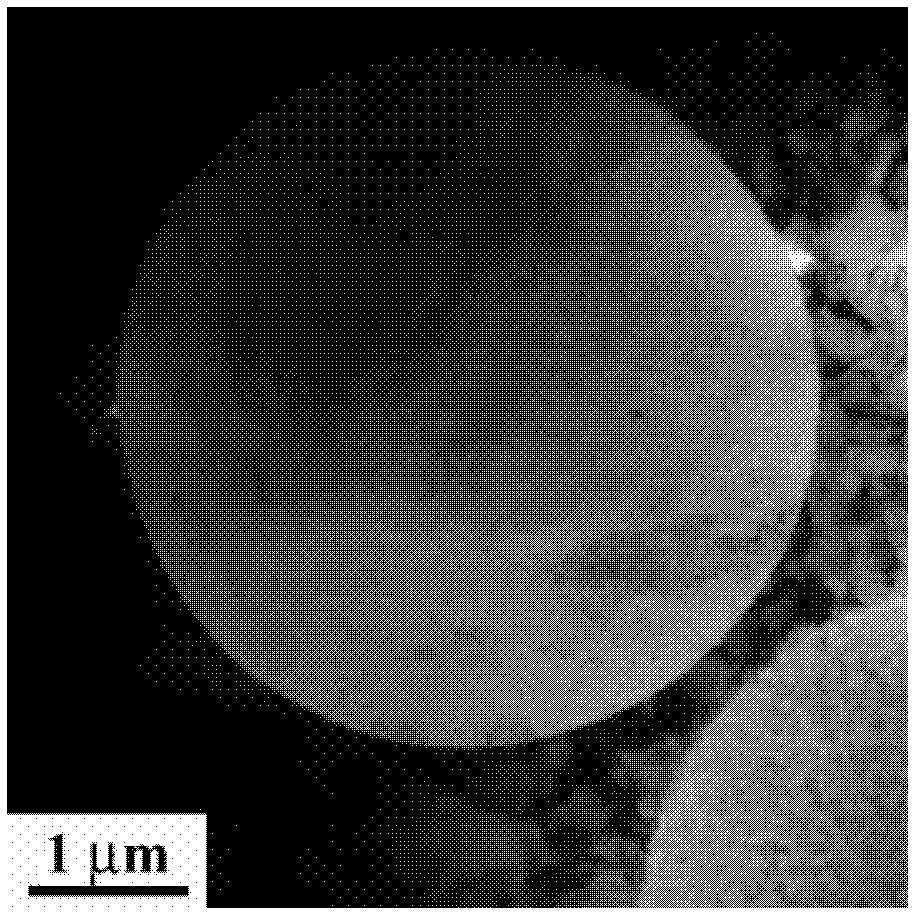

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the mechanical pre-thinning described in step three is performed as follows: the cathode obtains the copper on the rough product of the transmission electron microscope film of the rapidly solidified aluminum alloy powder The foil is completely removed, and then both sides are evenly polished until the thickness is 50±5μm. Finally, the crude transmission electron microscope film with a thickness of 50±5μm is immersed in a NaOH aqueous solution with a mass fraction of 10%, and the Al -Punching the area where the Fe-X alloy powder is concentrated, the diameter of the hole is 3mm, that is, the mechanical pre-thinning is completed, and the transmission electron microscope film sample of the fast solidified aluminum alloy powder after mechanical pre-thinning is obtained. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com