Method for removing and recovering copper and zinc in wastewater of copper-zinc catalysts

A catalyst, copper-zinc technology, applied in the field of industrial wastewater treatment, can solve the problems of excessive discharge of copper and zinc, achieve high purity, prolong the cleaning cycle, and avoid frequent shutdowns for cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

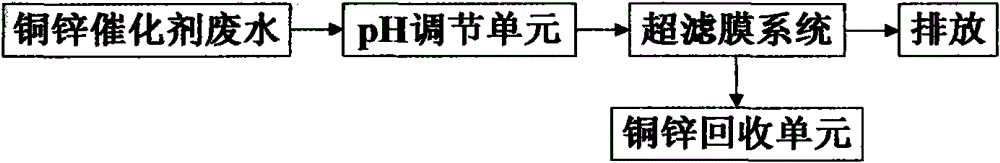

[0033] The water quality characteristics of the copper-zinc catalyst wastewater are: wastewater pH 8, COD cr 40mg / L, SS 20mg / L, Cu 20mg / L, Zn 30mg / L, NH 4 -N2 mg / L. The processing flow is attached figure 1 shown.

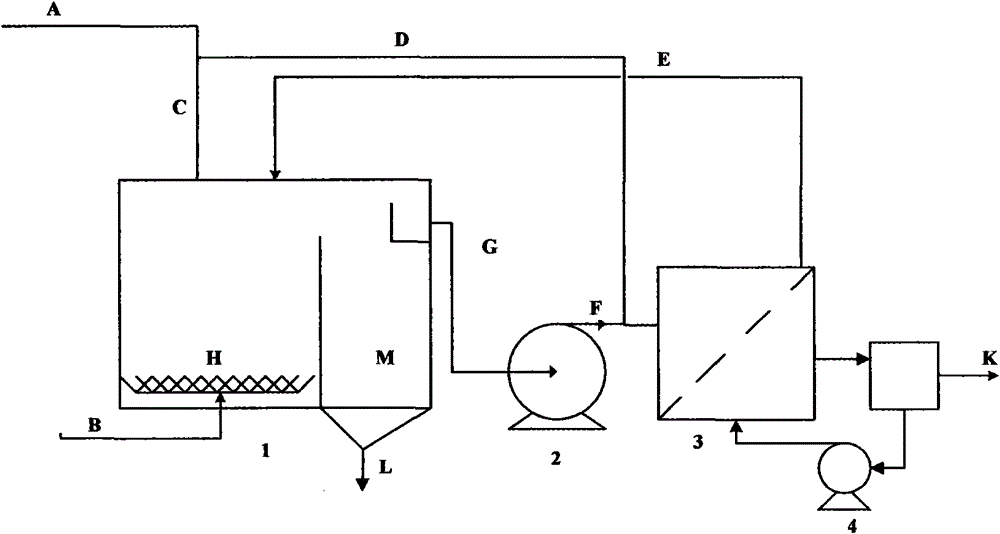

[0034] Copper-zinc catalyst waste water A directly enters the clarification and separation tank through route D, and the upper clarified liquid enters ultrafiltration pump 2 through route G to be pressurized and then undergoes ultrafiltration membrane system 3 for cross-flow filtration to separate copper-zinc colloids. The produced water meets the discharge standard and is concentrated The final copper-zinc-containing colloid is returned to the clarification separation unit for sedimentation and separation to recover copper and zinc. In this process, PPESK hollow fiber ultrafiltration membrane with a pore size of 0.01 μm is used, and the operating flux of the ultrafiltration membrane is 300L / m 2 h, after the time interval of alternating water inflow at both end...

Embodiment 2

[0037] Water quality characteristics of wastewater containing copper and zinc catalysts: wastewater pH5, COD cr 15mg / L, Cu 200mg / L, Zn 50mg / L, NH 4 -N 10mg / L, the treatment process is attached figure 1 shown.

[0038] Copper-zinc catalyst wastewater A enters the pH adjustment tank through route C to adjust the pH of the wastewater to 9 and directly enters the clarification and separation tank, and the upper clarified liquid enters the ultrafiltration pump 2 through route G. After pressurization, the ultrafiltration membrane system 3 is used for cross-flow filtration to separate copper and zinc. Colloid, the product water reaches the discharge standard, and the concentrated copper-zinc-containing colloid is returned to the clarification separation unit for sedimentation and separation to recover copper and zinc. In this process, a PTFE hollow fiber ultrafiltration membrane with a pore size of 0.01 μm is used, and the operating flux of the ultrafiltration membrane is 500L / m ...

Embodiment 3

[0041] Water quality characteristics of wastewater containing copper and zinc catalysts: wastewater pH 12, COD cr 60mg / L, Cu 200mg / L, Zn 50mg / L, NH 4 -N 5mg / L, the treatment process is attached figure 1 shown.

[0042] Copper-zinc catalyst waste water A enters the pH adjustment tank through route C to adjust the pH of the waste water to 7-11 and directly enters the clarification and separation tank, and the upper clarified liquid enters the ultrafiltration pump 2 through route G to pressurize and then proceed to the ultrafiltration membrane system 3 for cross-flow filtration and separation Copper-zinc colloid, the produced water meets the discharge standard, and the concentrated copper-zinc-containing colloid is returned to the clarification separation unit for sedimentation and separation to recover copper and zinc. In this process, a PVDF hollow fiber ultrafiltration membrane with a pore size of 0.015 μm is used, and the operating flux of the ultrafiltration membrane is 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com