Modified titanium dioxide grain, super-hydrophilic transparent thin film and preparation method thereof

A titanium dioxide and transparent film technology, which is applied in epoxy resin coatings, dyed low-molecular organic compound treatment, fibrous fillers, etc., can solve problems such as lack of industrial application prospects, poor operability, and limited hydrophilicity. Achieve the effects of good application and industrialization prospects, easy access to reaction raw materials, and good UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

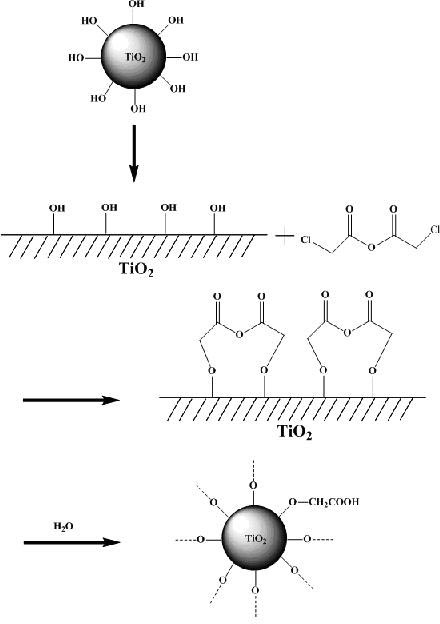

Method used

Image

Examples

Embodiment 1

[0025] Using a ball mill as a modification tool, add 1g of titanium dioxide particles to the ball mill jar, then add 1g of chloroacetic anhydride to the ball mill jar, add ball mill beads, seal the ball mill jar and fix it in the ball mill, and control the speed of the ball mill to 400 r / min , the ball milling time is 6h, take 1g of the particles prepared under this condition, add 25ml of water, continue the ball milling for 4h, and finally obtain carboxy-modified titanium dioxide particles.

[0026] Take 0.05 g of carboxy-modified titanium dioxide particles and disperse them in 1 g of epoxy resin (the epoxy resin has been dissolved in 10 g of ethanol under the conditions of heating and magnetic stirring) by ball milling to obtain a suspension with a concentration of 5 wt.%. The suspension was smeared on a glass slide and cured at 100°C for 3 hours to obtain a super-hydrophilic transparent film. The film is transparent in appearance, has the characteristics of certain UV prote...

Embodiment 2

[0028] Using a ball mill as a modification tool, add 1g of titanium dioxide particles to the ball mill jar, then add 1g of chloroacetic anhydride to the ball mill jar, add ball mill beads, seal the ball mill jar and fix it in the ball mill, and control the speed of the ball mill to 400 r / min , the ball milling time is 6h, take 1g of the particles prepared under this condition, add 25ml of water, continue the ball milling for 4h, and finally obtain carboxy-modified titanium dioxide particles.

[0029] Take 0.1 g of carboxy-modified titanium dioxide particles and disperse them in 1 g of epoxy resin (the epoxy resin has been dissolved in 10 g of ethanol under the conditions of heating and magnetic stirring) by ball milling to prepare a suspension with a concentration of 10 wt.%. The suspension was smeared on a glass slide and cured at 100°C for 3 hours to obtain a super-hydrophilic transparent film. The film is transparent in appearance, has the characteristics of certain UV prot...

Embodiment 3

[0031] Using a ball mill as a modification tool, add 1g of titanium dioxide particles to the ball mill jar, then add 1g of chloroacetic anhydride to the ball mill jar, add ball mill beads, seal the ball mill jar and fix it in the ball mill, and control the speed of the ball mill to 400 r / min , the ball milling time is 6h, take 1g of the particles prepared under this condition, add 25ml of water, continue the ball milling for 4h, and finally obtain carboxy-modified titanium dioxide particles.

[0032] Take 0.05 g of carboxy-modified titanium dioxide particles and disperse them in 1 g of epoxy resin (the epoxy resin has been dissolved in 10 g of ethanol under the conditions of heating and magnetic stirring) by ball milling to obtain a suspension with a concentration of 5 wt.%. The suspension was smeared on a glass slide and cured at 100°C for 3 hours to obtain a super-hydrophilic transparent film. The film is transparent in appearance, has the characteristics of certain UV prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com