Manufacturing method of phase change memory storage unit

A technology of phase-change memory and storage unit, which is applied in the direction of electrical components, semiconductor devices, electric solid-state devices, etc., and can solve the problems of reducing the yield rate of phase-change memory, increasing the poor contact between the bottom electrode and the phase-change layer, and damage to the storage unit of the phase-change memory and other issues to achieve the effect of avoiding partial discharge phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

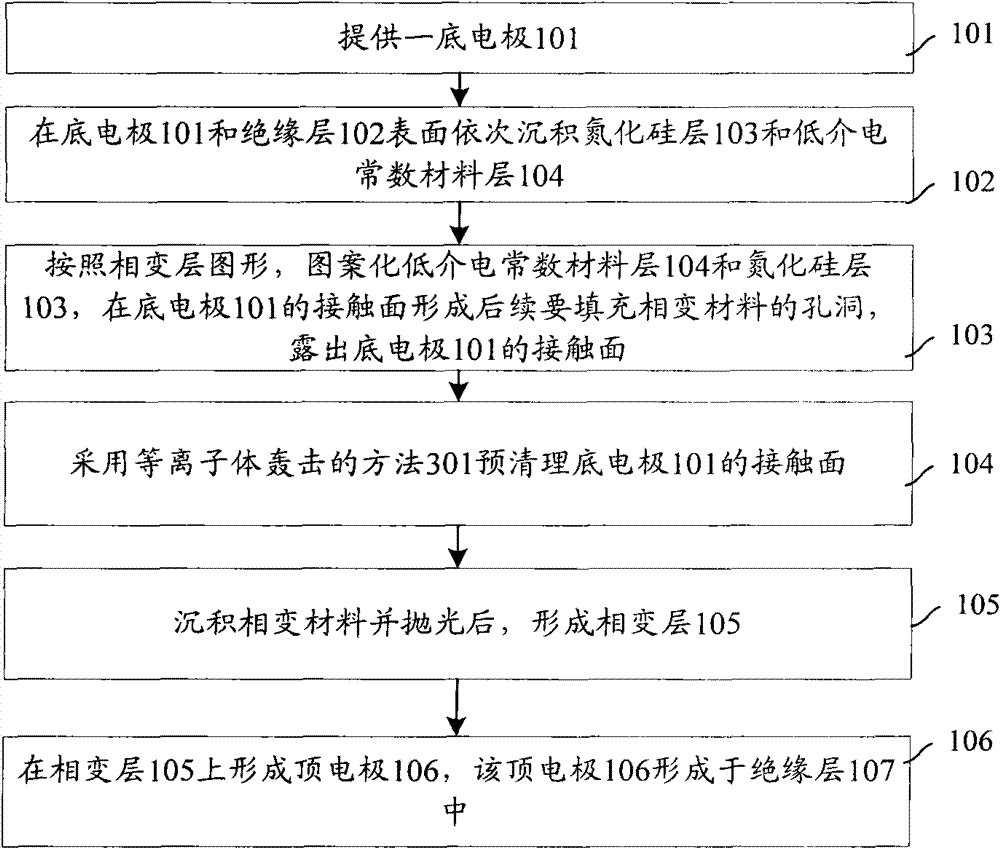

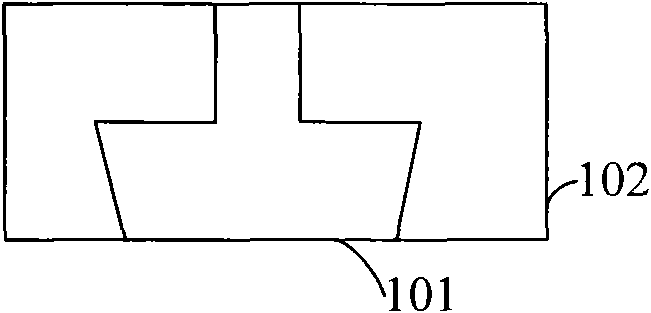

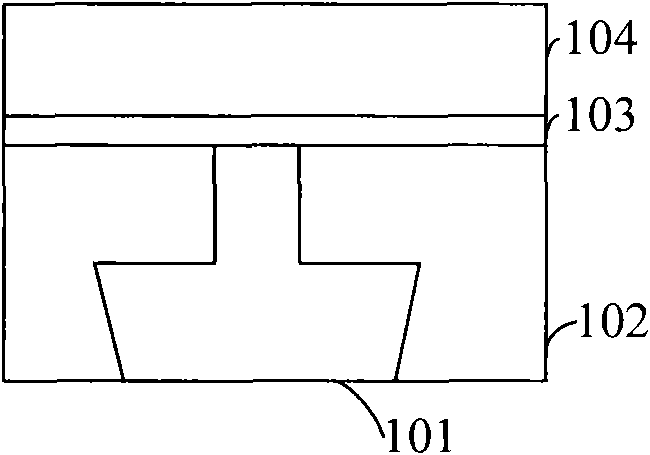

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0038] In the present invention, in order to avoid the partial discharge phenomenon in the pre-cleaning process when making the phase change memory storage unit, and to prevent the final phase change memory storage unit from being damaged, the gas phase deposition method is used to be affected by the holes to form the phase change layer. Obviously, while the method of plasma bombardment is affected by the small characteristics of the holes to form the phase change layer, the following method is adopted:

[0039] Before the contact surface of the bottom electrode 101 is pre-cleaned by plasma bombardment, a layer of phase change material is deposited as a sacrificial layer and a protective layer for cleaning the bottom electrode 101 . Because the aspect r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com