Trimetazidine hydrochloride sustained release tablet and preparation method thereof

A technology for trimetazidine hydrochloride and sustained-release tablets, which is applied in the direction of pharmaceutical formulas, medical preparations containing no active ingredients, medical preparations containing active ingredients, etc., which can solve the problem of large side effects, short effective blood drug concentration maintenance time, The effect of medicine can not be exerted smoothly and other problems, so as to achieve the effect of easy operation, reducing the frequency of taking medicine and improving compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

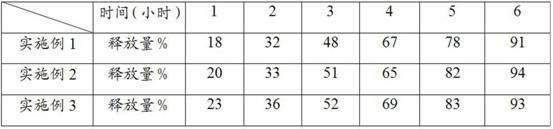

Examples

preparation example Construction

[0031] A preparation method of trimetazidine hydrochloride sustained-release tablet, which comprises the following steps:

[0032] (1) Mixing: Stir and mix trimetazidine hydrochloride, polyoxyethylene, and dextrin in a mixer according to the formula amount;

[0033] (2) Making soft material: add ethyl cellulose liquid to the above mixed components and mix evenly to make soft material, and granulate with a 16-mesh sieve in a granulator to obtain soft drug granules;

[0034] (3) Drying: the above-mentioned soft medicine granules are dried in a drying oven;

[0035] (4) Tablet compression: the above-mentioned dried granules are uniformly mixed with magnesium stearate, and compressed into tablets to obtain sustained-release tablets.

Embodiment 1

[0037] The following formula, according to the above-mentioned preparation method, is made into 2000 trimetazidine hydrochloride sustained-release tablets, and each sustained-release tablet finally obtained weighs about 170mg:

[0038] Trimetazidine Hydrochloride 40g

[0039] Polyoxyethylene 100g

[0040] Dextrin 200g

[0041] 3% ethyl cellulose solution 60g

Embodiment 2

[0044] The following formula, according to the above-mentioned preparation method, is made into 2000 trimetazidine hydrochloride sustained-release tablets, and each sustained-release tablet finally obtained weighs about 170mg:

[0045] Trimetazidine Hydrochloride 40g

[0046] Polyoxyethylene 150g

[0047] Dextrin 150g

[0048] 5% ethyl cellulose solution 80g

[0049] Magnesium stearate 3g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com