Method for biologic pretreatment of lignocellulose and hydrogen production through simultaneous saccharification and fermentation

A simultaneous saccharification and fermentation, lignocellulose technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of fermentation inhibitors, pollute the environment, and high energy demand, and achieve cost reduction and equipment reduction Investment, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

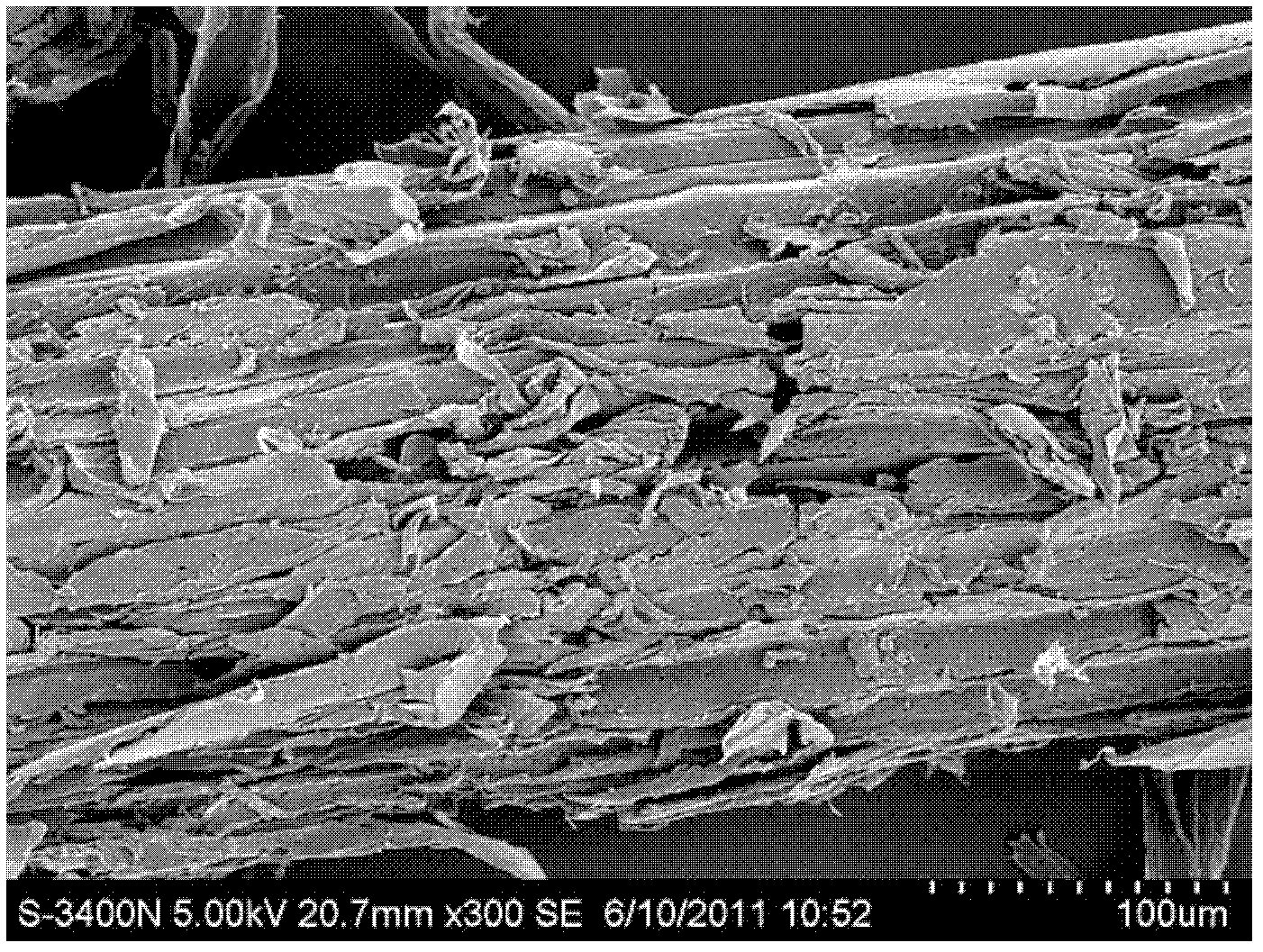

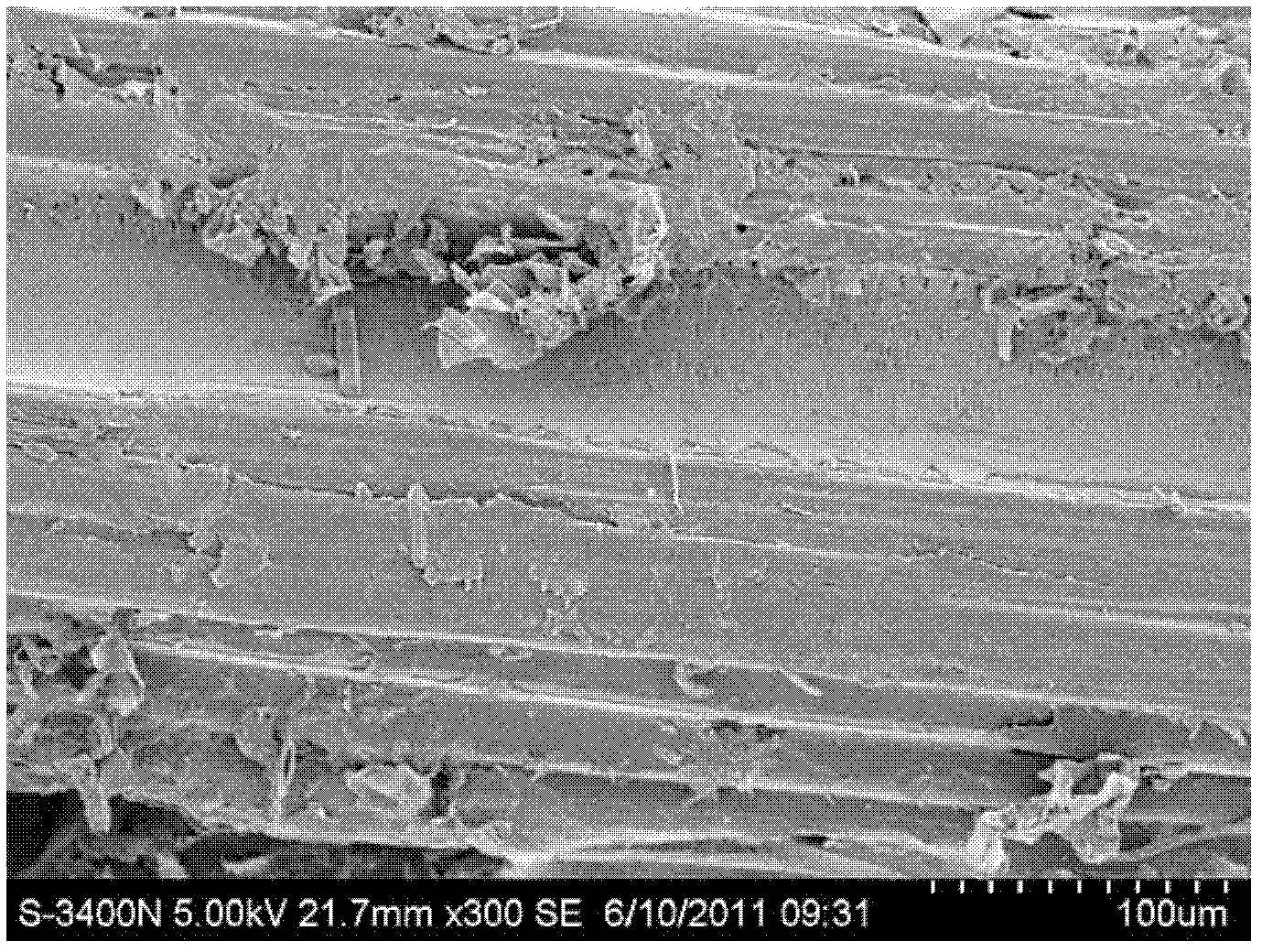

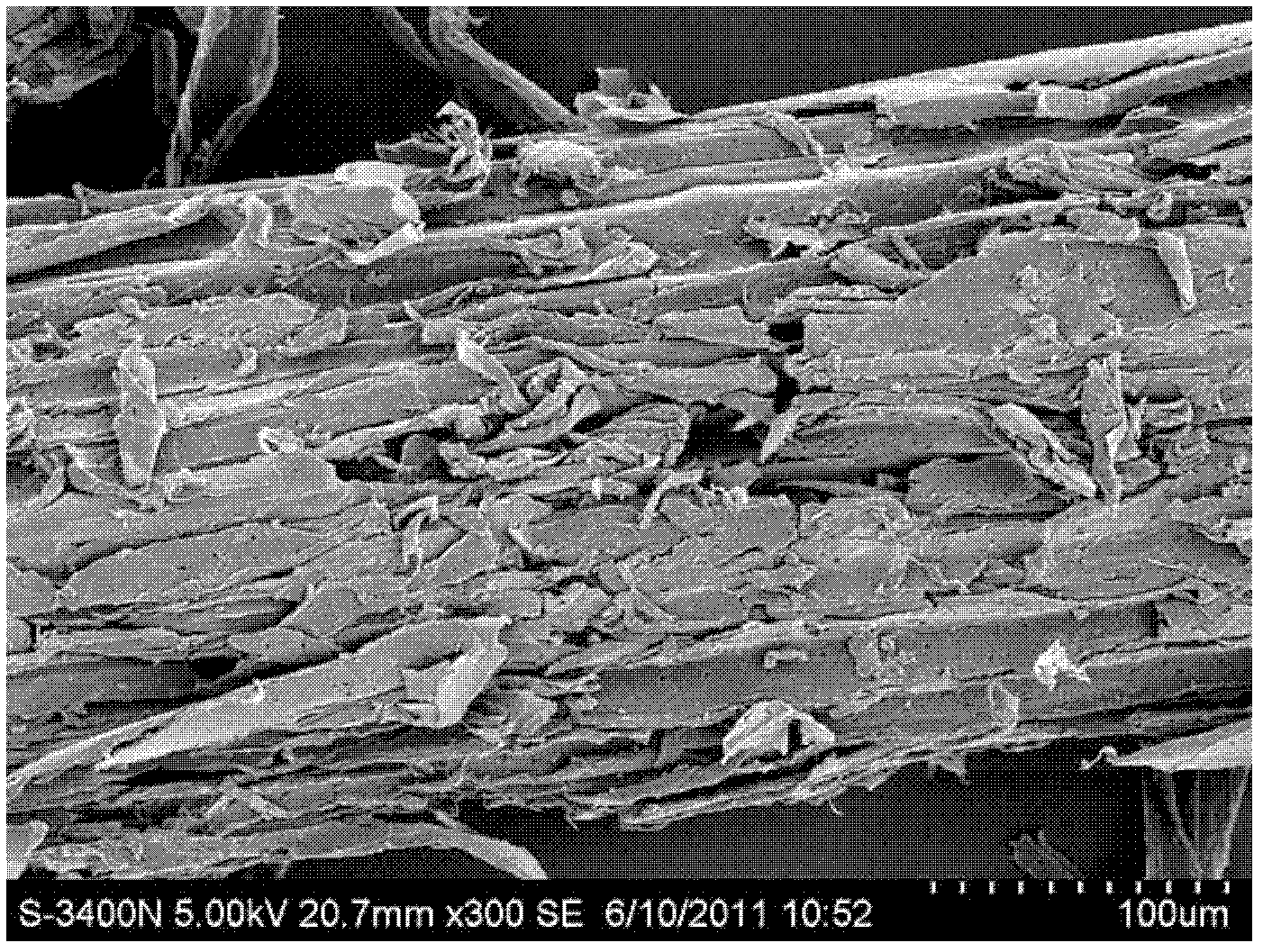

[0014] Specific Embodiment 1: In this embodiment, the method for biological pretreatment of lignocellulose and synchronous saccharification and fermentation for hydrogen production is realized according to the following steps:

[0015] 1. Inoculate white rot fungi in lignocellulose liquid medium, culture in suspension under aerobic conditions at 29°C for 10 to 20 days, then wash with water, and dry in an oven at 105°C to constant weight to obtain pretreatment cellulose; 2. Mix 3L hydrogen-producing bacteria nutrient salt solution with 7L Trichoderma viride crude enzyme solution, add 150-350g pretreated cellulose to obtain synchronous saccharification and fermentation hydrogen production medium, and then pass it into % nitrogen, then inoculate the seed solution of hydrogen-producing bacteria, and carry out anaerobic fermentation to produce hydrogen for 24-72 hours under the conditions of initial pH value of 6.5, temperature of 60°C, and stirring speed of 150r / min; that is, the b...

specific Embodiment approach 2

[0026] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: in step 1, the inoculation of white rot fungi adopts a concentration of 2×10 6 spores / ml of spore suspension, the inoculation volume of each bottle is 2×10 7 spores. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0027] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the hydrogen-producing bacteria in the seed liquid of hydrogen-producing bacteria in step 2 is thermosaccharolyticum anaerobic bacillus W16 (Thermoanaerobacterium thermosaccharolyticum W16), and Thermoanaerobacterium thermosaccharolyticum W16 was established in 2008 It is disclosed in an article titled "Dark fermentation of xylose and glucose mix using isolated Thermoanaerobacterium thermosaccharolyticum W16" published in "International Journal of Hydrogen Energy", No. 33, pages 6124-6132. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com