High-spreadability tin-antimony-rare earth lead-free solder alloy and preparation method thereof

A lead-free solder alloy and spreadability technology, applied in welding equipment, metal processing equipment, welding/cutting media/materials, etc., can solve the problems of high melting point, limited spreading performance, and restrictions on the wide use of materials, and achieve low melting point, Guarantee the performance of welding process and facilitate the effect of industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

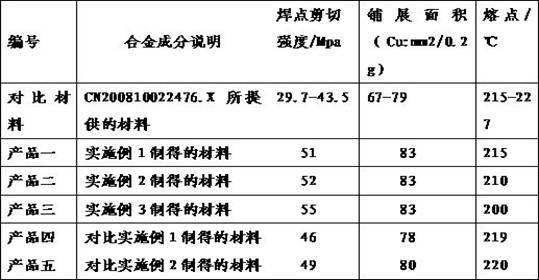

Embodiment 1

[0020] The raw materials are formulated according to the following mass percentages: Sb7wt%, In0.01wt%, Bi1wt%, Cd0.01wt%, Sm0.01wt%, Nd0.01wt%, and the balance is Sn.

[0021] The above raw materials are melted in a vacuum induction furnace at a melting temperature of 520°C to obtain a master alloy, and then put into a remelting tubular crucible in a vacuum induction quenching furnace for remelting at a remelting temperature of 360°C. The bottom of the tubular crucible is placed 2-4mm above the rim of the runner of the quenching furnace. The above-mentioned master alloy is placed in the tubular crucible and melted. The spray is in contact with the edge of the rotating runner to form an alloy strip with a thickness of 200-250 microns and a width of 3-6 mm; the rotational speed of the rim of the runner is 12m / s; then the alloy strip is pulverized and then placed After grinding in a ball mill for 20 minutes, take out and sieve, and take and sieve to obtain alloy particles with a...

Embodiment 2

[0023] The raw materials are formulated according to the following mass percentages: Sb9wt%, In0.03wt%, Bi3wt%, Cd0.03wt%, Sm0.03wt%, Nd0.03wt%, and the balance is Sn.

[0024] The above raw materials are melted in a vacuum induction furnace at a melting temperature of 510°C to obtain a master alloy, and then put into a remelting tubular crucible in a vacuum induction quenching furnace for remelting at a remelting temperature of 370°C. The bottom of the tubular crucible is placed 2-4mm above the rim of the runner of the quenching furnace. The above-mentioned master alloy is placed in the tubular crucible and melted. The spray is in contact with the edge of the rotating runner to form an alloy strip with a thickness of 200-250 microns and a width of 3-6 mm; the rotational speed of the rim of the runner is 12m / s; then the alloy strip is pulverized and then placed After grinding in a ball mill for 20 minutes, take out and sieve, and take and sieve to obtain alloy particles with a...

Embodiment 3

[0026] The raw materials are formulated according to the following mass percentages: Sb8wt%, In0.02wt%, Bi2wt%, Cd0.02wt%, Sm0.02wt%, Nd0.02wt%, and the balance is Sn.

[0027] The above raw materials are melted in a vacuum induction furnace at a melting temperature of 520°C to obtain a master alloy, and then put into a remelting tubular crucible in a vacuum induction quenching furnace for remelting at a remelting temperature of 360°C. The bottom of the tubular crucible is placed 2-4mm above the rim of the runner of the quenching furnace. The above-mentioned master alloy is placed in the tubular crucible and melted. The spray is in contact with the edge of the rotating runner to form an alloy strip with a thickness of 200-250 microns and a width of 3-6 mm; the rotational speed of the rim of the runner is 13m / s; then the alloy strip is pulverized and then placed After grinding in a ball mill for 15 minutes, take out and sieve, and take and sieve to obtain alloy particles with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com