Method for quickly determining gold, palladium, platinum, rhodium, iridium, silver, nickel, copper and iron in rare and precious metal system

A rare and precious metal solution technology, applied in the field of rapid determination of iridium, copper, palladium, platinum, nickel, iron, rhodium, gold and silver in materials rich in precious metals. To achieve the effect of reducing labor intensity and health hazards, stable and reliable analysis results, and avoiding large-scale use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

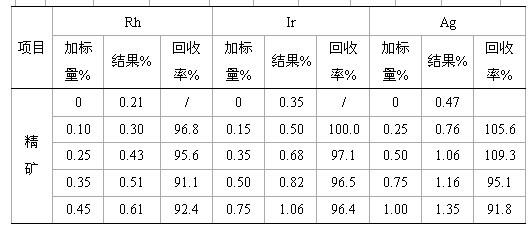

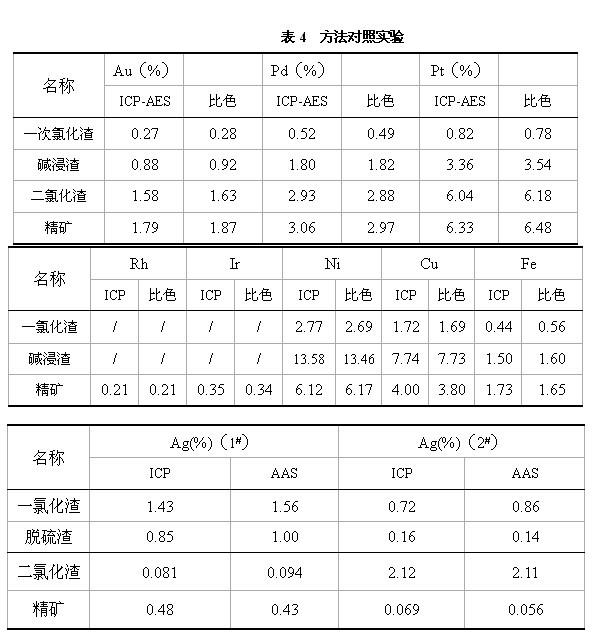

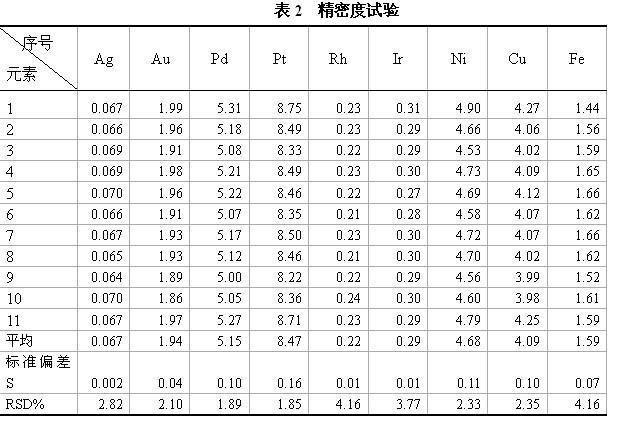

Examples

Embodiment Construction

[0045] The present invention is applicable only to reagents and distilled or deionized water or water of equivalent purity which are confirmed to be analytically pure.

[0046] A rapid determination method for gold, palladium, platinum, rhodium, iridium, silver, nickel, copper and iron in a rare and precious metal system. The determination is based on the detection principle of inductively coupled plasma emission spectrometry. Curve drawing, interference and its elimination, detection limit and accuracy, among which:

[0047] 1. Experimental conditions

[0048] 1) Instrument selection: choose iCAP6300 inductively coupled plasma emission spectrometer, the best parameters for using this instrument are: high frequency generator power: 1150W, auxiliary gas flow: 0.5L / min, pump speed: 50r / min, vertical observation Height: 15mm;

[0049] 2) Selection of analytical spectral lines: The selection of spectral lines follows the principle of high sensitivity and less interference of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com