Metal film resistor structure and manufacturing method thereof

一种金属薄膜电阻、制造方法的技术,应用在电阻器、半导体/固态器件制造、电路等方向,能够解决金属薄膜电阻易于损伤等问题,达到提高可靠性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

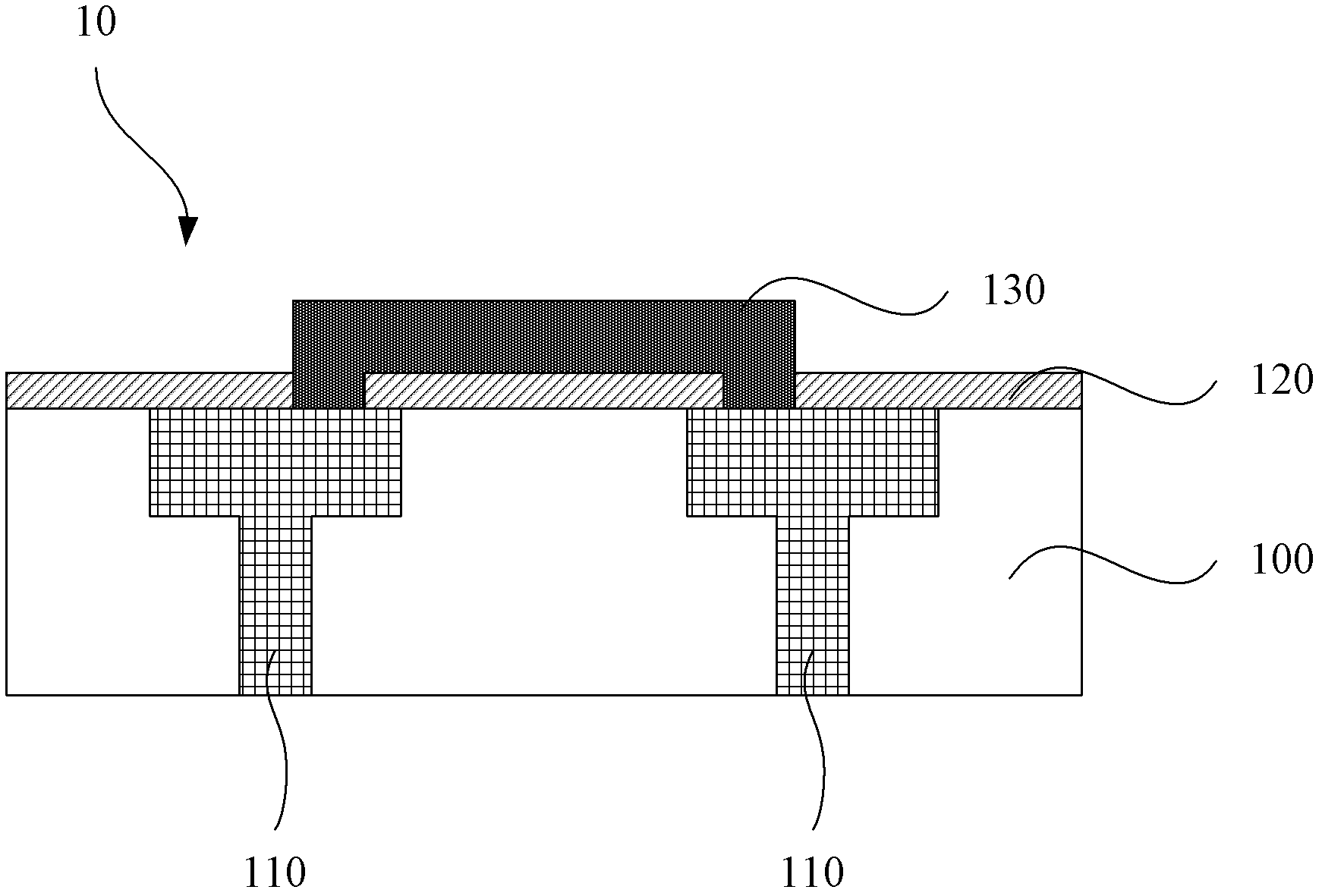

[0052] Please refer to Figure 3a ~ 3f , which is a schematic cross-sectional view of the manufacturing method of the metal thin film resistor structure according to Embodiment 1 of the present invention.

[0053] Such as Figure 3a As shown, firstly, an insulating layer 300 is provided, and an underlying metal copper interconnection line 310 is formed in the insulating layer 300 . The material of the insulating layer 300 can be SiO 2 , FSG (fluorine-doped silicon dioxide, SiOF) and other low-K dielectric materials.

[0054] Such as Figure 3b As shown, secondly, a capping layer 320 is formed on the insulating layer 300 and the underlying metal copper interconnection 310 . In this embodiment, the capping layer 320 includes: a diffusion barrier layer 321 and a thickened layer 322 . The diffusion barrier layer 321 can prevent the copper diffusion in the lower metal copper interconnection line 310 , the material of which can be silicon nitride or silicon carbide, and the thi...

Embodiment 2

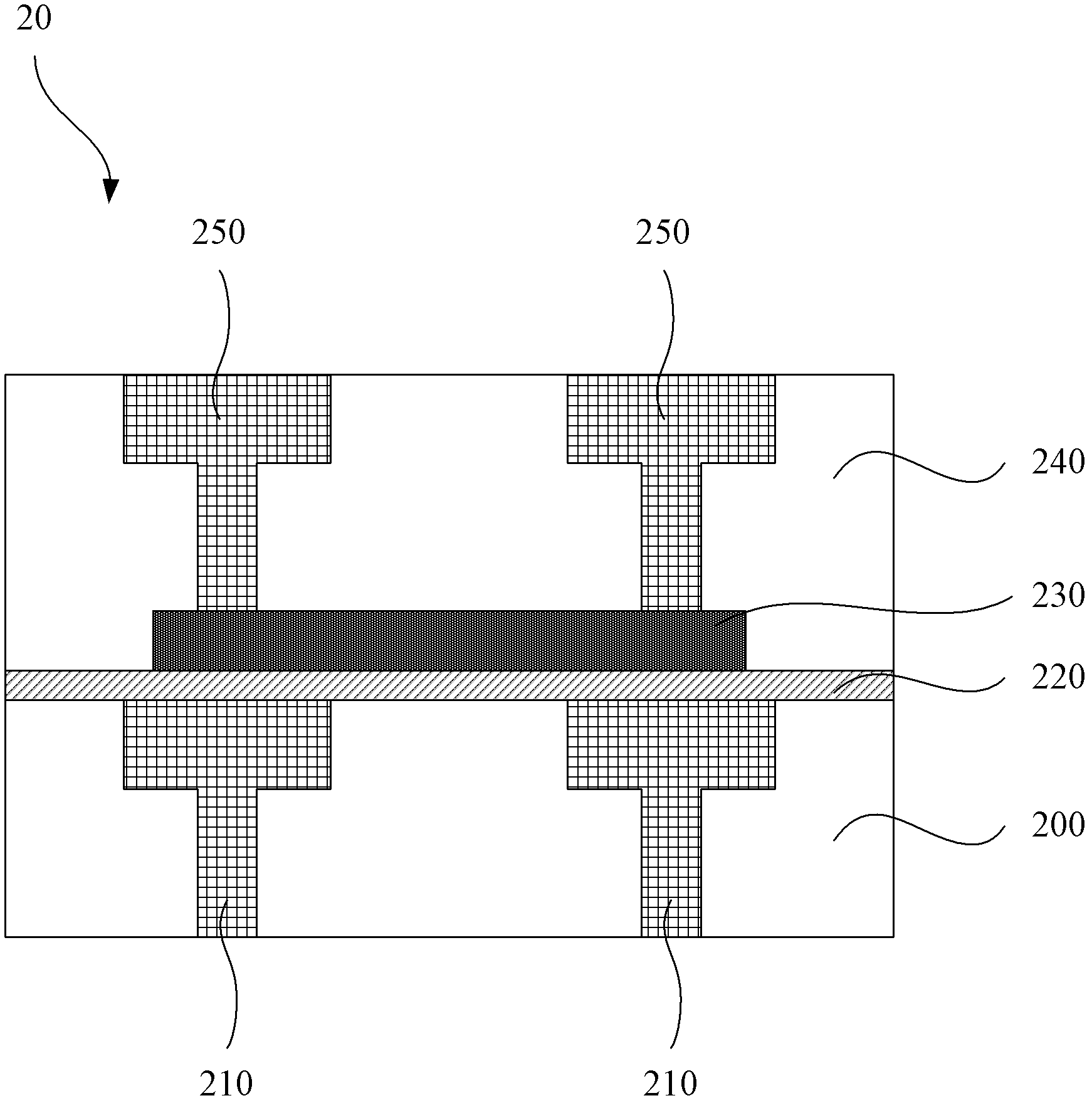

[0062] Please refer to Figure 5a-5f , which is a schematic cross-sectional view of the manufacturing method of the metal thin film resistor structure according to the second embodiment of the present invention.

[0063] Such as Figure 5a As shown, firstly, an insulating layer 500 is provided, and an underlying metal copper interconnection line 510 is formed in the insulating layer 500 . The material of the insulating layer 500 can be SiO 2 , FSG and other low K dielectric materials.

[0064] Such as Figure 5b As shown, secondly, a capping layer 520 is formed on the insulating layer 500 and the underlying metal copper interconnection 510 . In this embodiment, the capping layer 520 is a diffusion barrier layer. The diffusion barrier layer can block the copper diffusion in the lower metal copper interconnection 510 , and its material can be silicon nitride or silicon carbide, and the thickness of the diffusion barrier layer can be 150 angstroms to 700 angstroms.

[0065]...

Embodiment 3

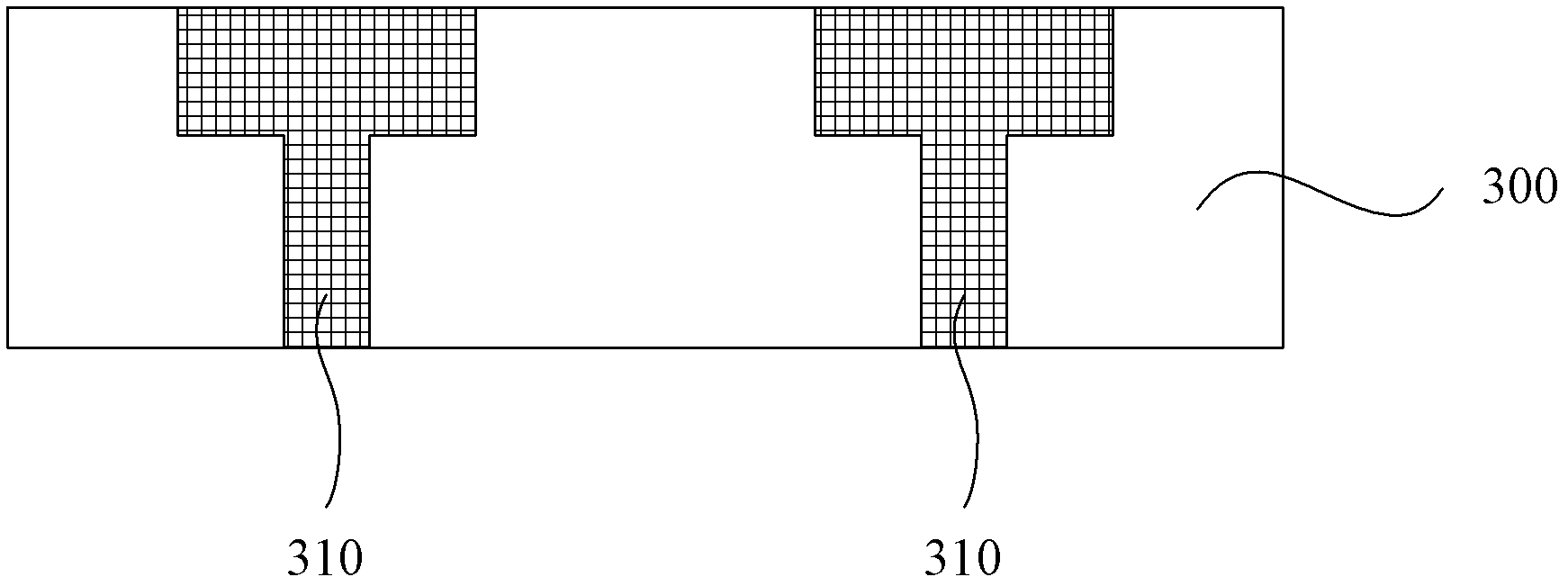

[0071] Please refer to Figure 6a~6c , which is a schematic cross-sectional view of the manufacturing method of the metal thin film resistor structure according to the third embodiment of the present invention.

[0072] Such as Figure 6a As shown, firstly, an insulating layer 600 is provided, and an underlying metal copper interconnection line 610 is formed in the insulating layer 600 . The material of the insulating layer 600 can be SiO 2 , FSG and other low K dielectric materials.

[0073] Such as Figure 6b As shown, next, a metal thin film layer 620 is formed on the insulating layer 600 and the underlying metal copper interconnection 610 . In this embodiment, the metal thin film layer 620 may be formed by a physical vapor deposition process, a chemical vapor deposition process or an atomic layer deposition process, and the thickness of the metal thin film layer 620 may be 50 angstroms to 2000 angstroms. The material of the metal thin film layer 620 can be W, WN x , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com