Preparation method for LED (Light Emitting Diode) fluorescent powder

A technology of phosphor powder and alkaline earth metal, applied in the field of phosphor powder, can solve the problems that the color rendering index of the device is difficult to reach more than 80, hindering the development of white LED light-emitting devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

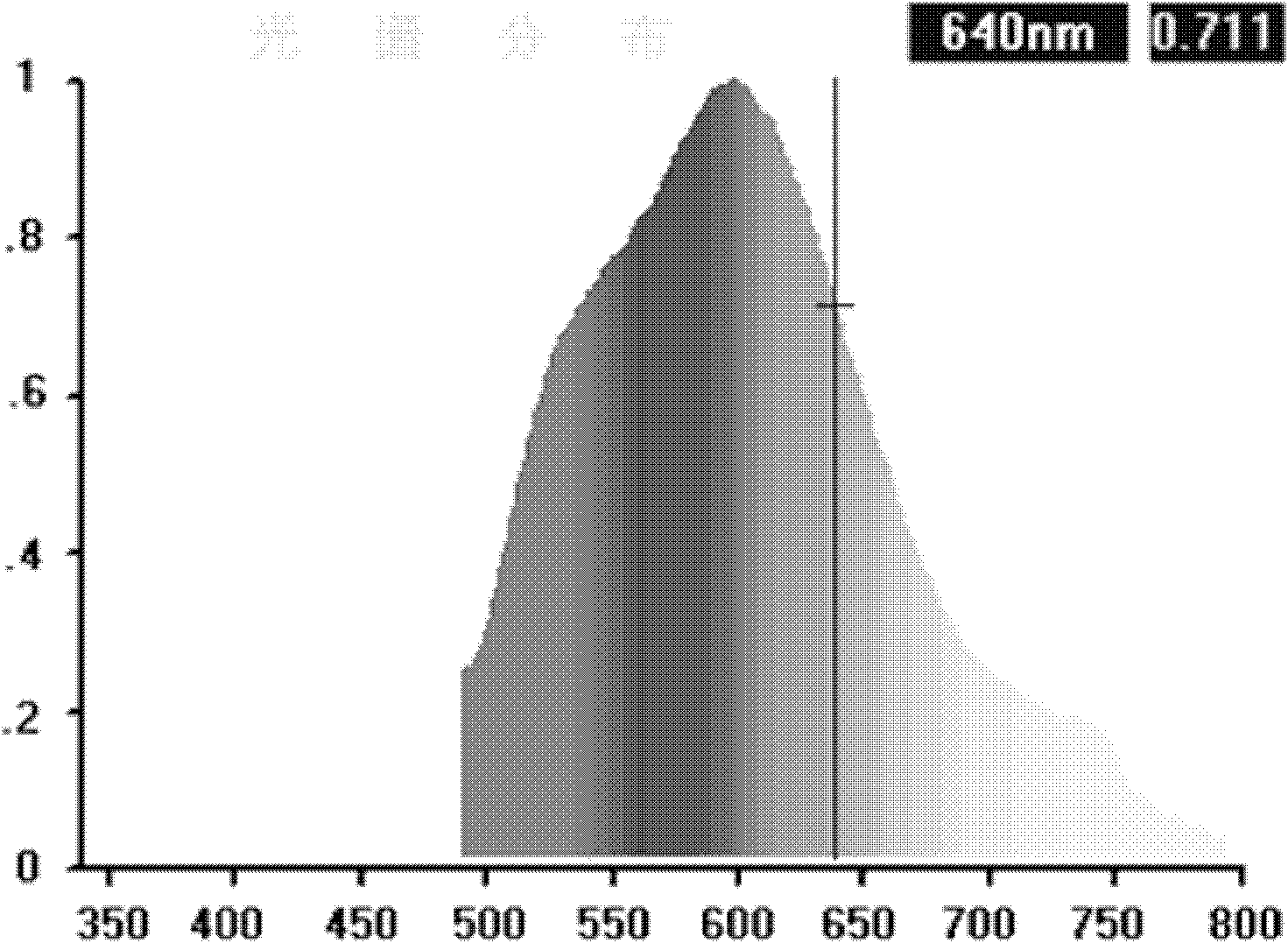

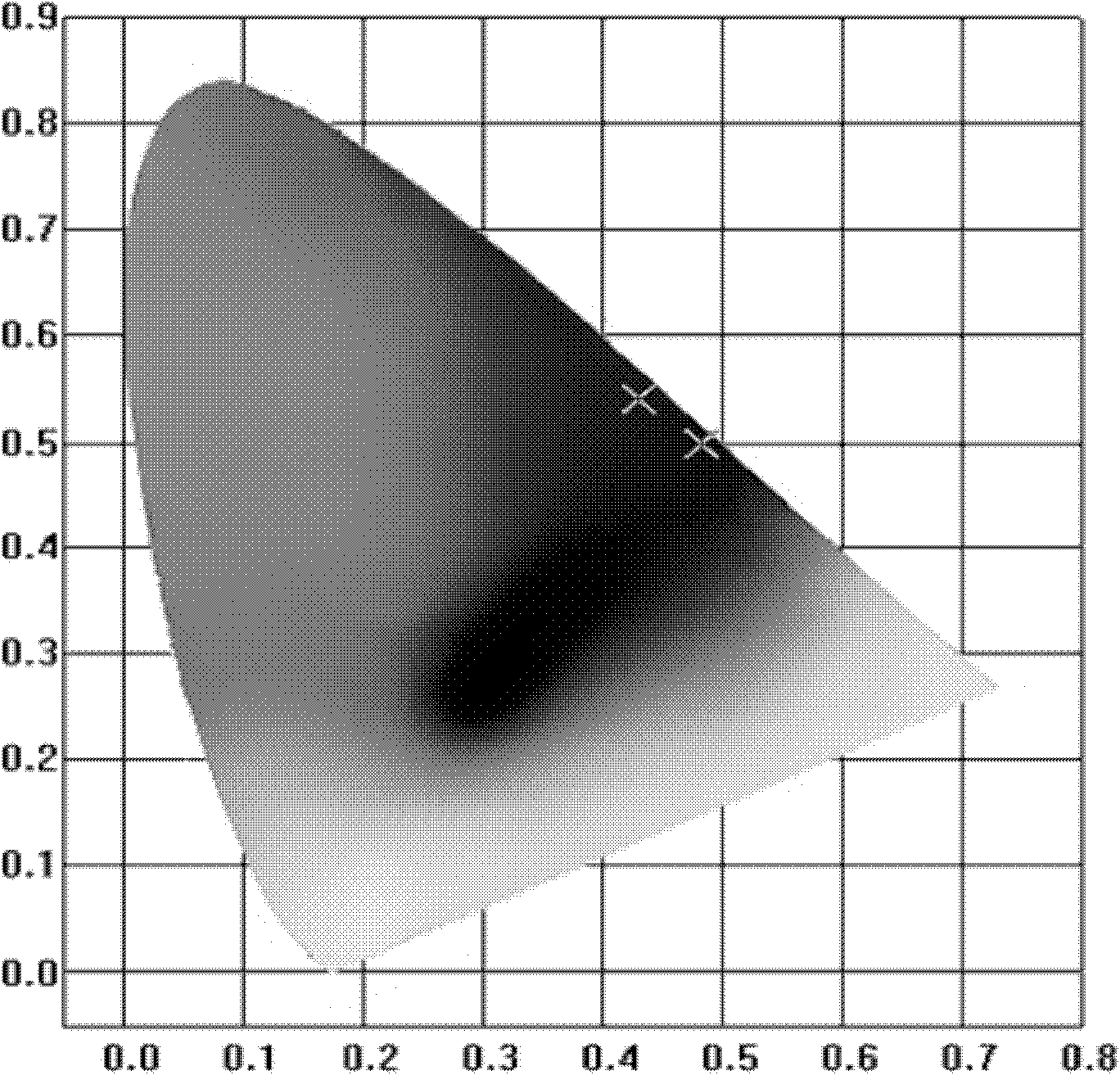

[0025] The present invention Y 3.93 GdGa 5 CaO 16 : Ce 3+ 0.04 Eu 2+ 0.03 Phosphor powder can be prepared using the following methods:

[0026] According to the above-mentioned general formula, weigh the yttrium oxide Y respectively according to the molar ratio 2 o 3 372.9g, gallium oxide Ga 2 o 3 468.5g, gadolinium oxide Gd 2 o 3 181.2g, calcium oxide CaO 88.0g, cerium oxide Ce 2 o 4 6.88g, europium oxide Eu 2 o 3 10.55g, add 3wt% of the above total amount of yttrium fluoride, cerium fluoride mixed flux according to the mass ratio of 2:3, mix and grind the mixture in the forced mixer for 30min, then put it into an alumina crucible and put it in a high-temperature furnace The volume ratio of nitrogen-hydrogen mixed gas into the inner 2 :H 2 = 3:1 reducing atmosphere, heat preservation at 1300°C for 2 hours, then heat up to 1650°C for 5 hours, keep the reducing atmosphere until natural cooling, and obtain phosphor. After high-temperature roasting and cooli...

Embodiment 2

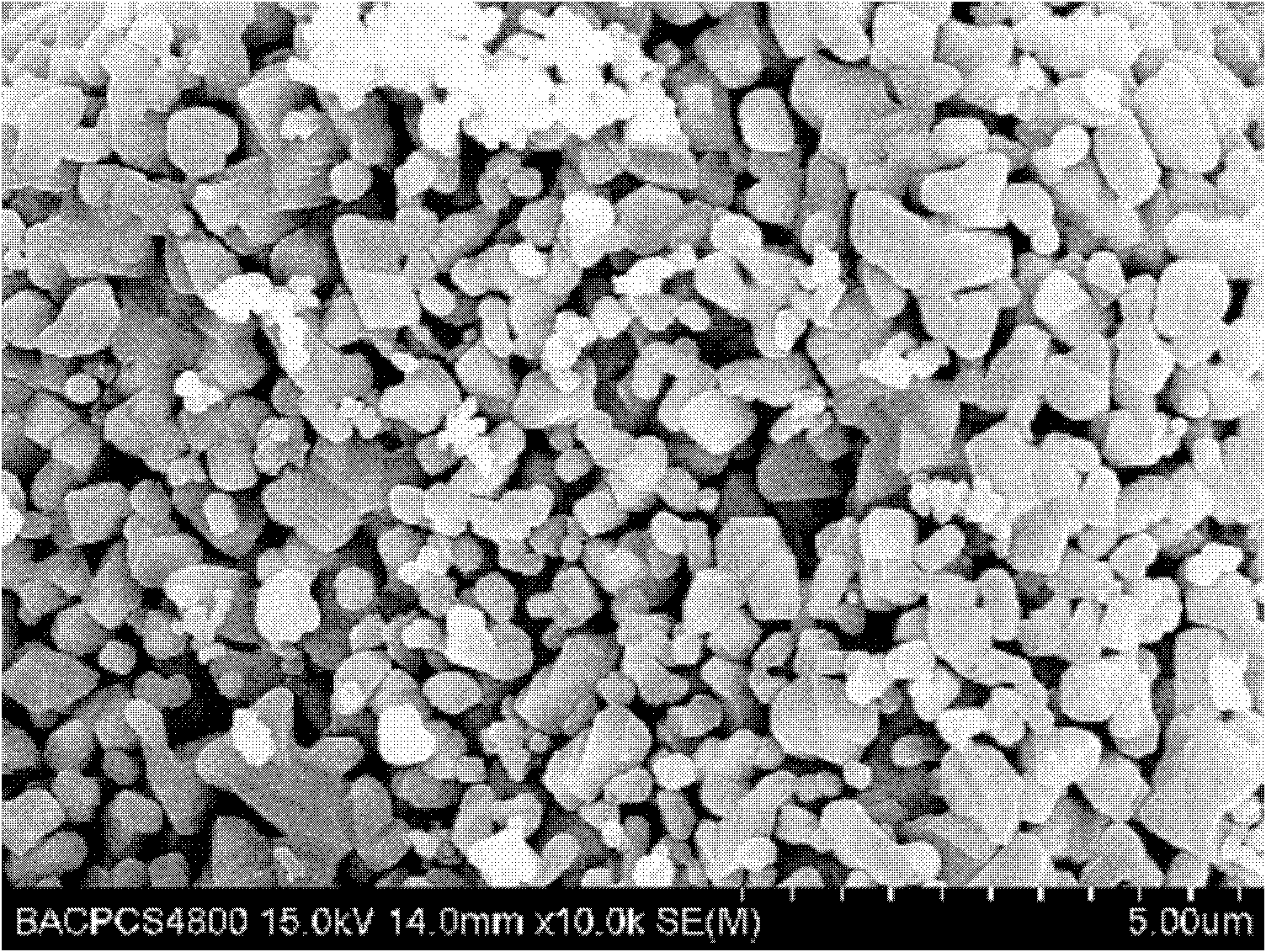

[0029] The present invention Y 3.93 GdGa 5 CaO 16 : Ce 3+ 0.04 Eu 2+ 0.03 Small particle phosphors can be prepared using the following methods:

[0030] According to the above-mentioned general formula, weigh the yttrium oxide Y respectively according to the molar ratio 2 o 3 372.9g, gallium oxide Ga 2 o 3 468.5g, gadolinium oxide Gd 2 o 3 181.2g, calcium oxide CaO 88.0g, cerium oxide Ce 2 o 4 6.88g, europium oxide Eu 2 o 3 10.55g, add the above-mentioned yttrium fluoride, barium fluoride and cerium fluoride in a total amount of 8wt%, distribute the above three fluxes according to the mass ratio of 2:3:0.5, and mix them uniformly. After the above raw materials and flux are mixed evenly, the mixture is mixed and ground in a forced mixer for 30 minutes; the obtained mixture is put into a corundum crucible, and a nitrogen-hydrogen mixed gas with a volume ratio of N 2 :H 2 = 5:1 reducing atmosphere, heat preservation at 1300°C for 2 hours, then heat up to 1500°...

Embodiment 3

[0033] The present invention Y 3.85 GdGa 5 CaO 16 : Ce 3+ 0.05 Eu 2+ 0.1 Phosphor powder can be prepared using the following methods:

[0034] According to the above-mentioned general formula, weigh the yttrium oxide Y respectively according to the molar ratio 2 o 3 365.15g, gallium oxide Ga 2 o 3 468.5g, gadolinium oxide Gd 2 o 3 181.2g, calcium oxide Ca 2 o 3 88.0g, cerium oxide Ce 2 o 4 8.6g, europium oxide Eu 2 o 3 35.16g, add the above-mentioned yttrium fluoride, barium fluoride and cerium fluoride in an amount of 1wt%, distribute the above three fluxes according to the mass ratio of 2:3:0.5, and mix them evenly. After mixing the above raw materials and flux evenly, put the obtained mixture into a corundum crucible, pass pure hydrogen into a high-temperature furnace as a reducing atmosphere, keep it at 1300°C for 2 hours, and bake it at 1600°C for 7 hours, and keep the reducing atmosphere until After natural cooling, get Y 3.85 GdGa 5 CaO 16 : Ce ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spectroscopy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com