Preparation methods of neodymium and nickel co-doped bismuth ferrite photocatalyst and composite catalyst thereof

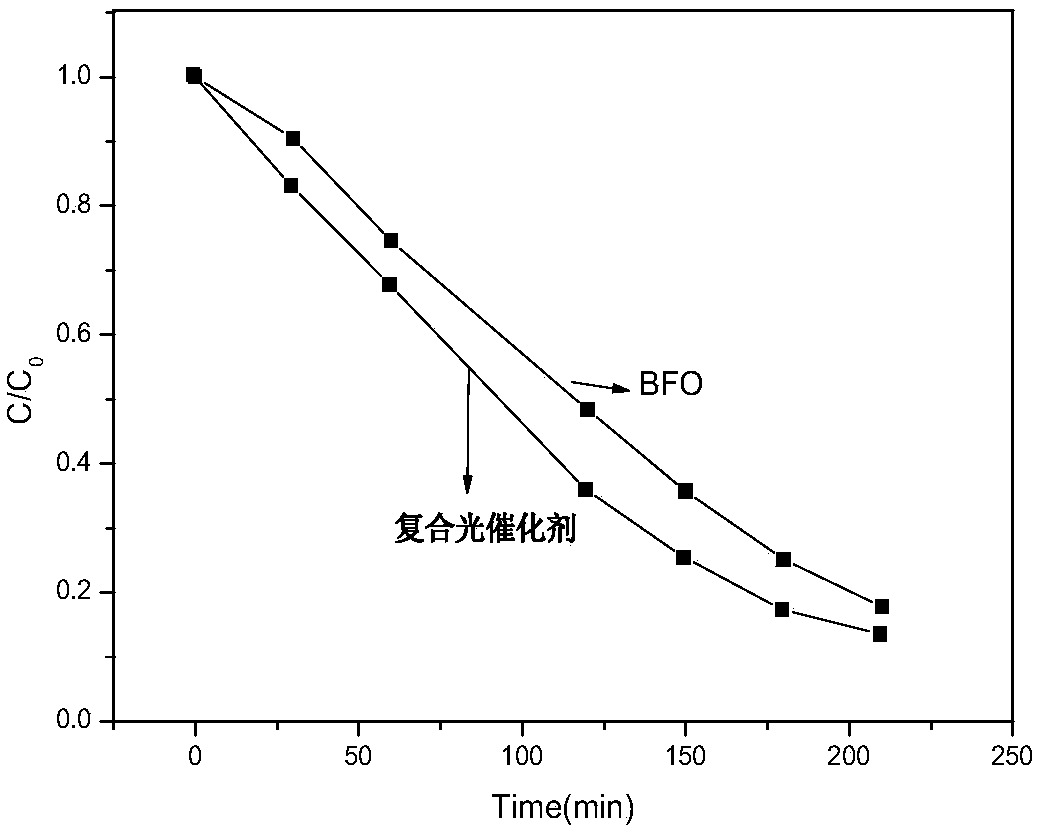

A technology of photocatalyst and bismuth ferrite, which is applied in the field of photocatalysis, can solve the problems of difficult recycling, weak magnetism, and insufficient catalytic activity, and achieve the effects of easy recycling, good magnetism, and optimized hydrothermal process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Prepare a KOH solution with a molar concentration of 7mol / L;

[0033] (2) Measure the KOH solution, then weigh the Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O, Nd(NO 3 ) 3 ·6H 2 O and Ni(NO 3 ) 2 ·6H 2 O, dissolve them in the above-mentioned KOH solution, stir for 1 h after ultrasonication for 10 min to obtain a uniform suspension;

[0034] (3) Control the temperature of the suspension obtained in step (2) to 190° C. for hydrothermal reaction for 10 h, and then naturally cool to room temperature to obtain a reaction solution;

[0035] (4) Ultrasonic wash the reaction solution obtained in step (3) with deionized water, let it stand until the upper and lower layers are clearly separated, pour off the supernatant, and dry the resulting precipitate at a temperature of 60°C to obtain neodymium and nickel co-doped Bismuth ferrite photocatalyst.

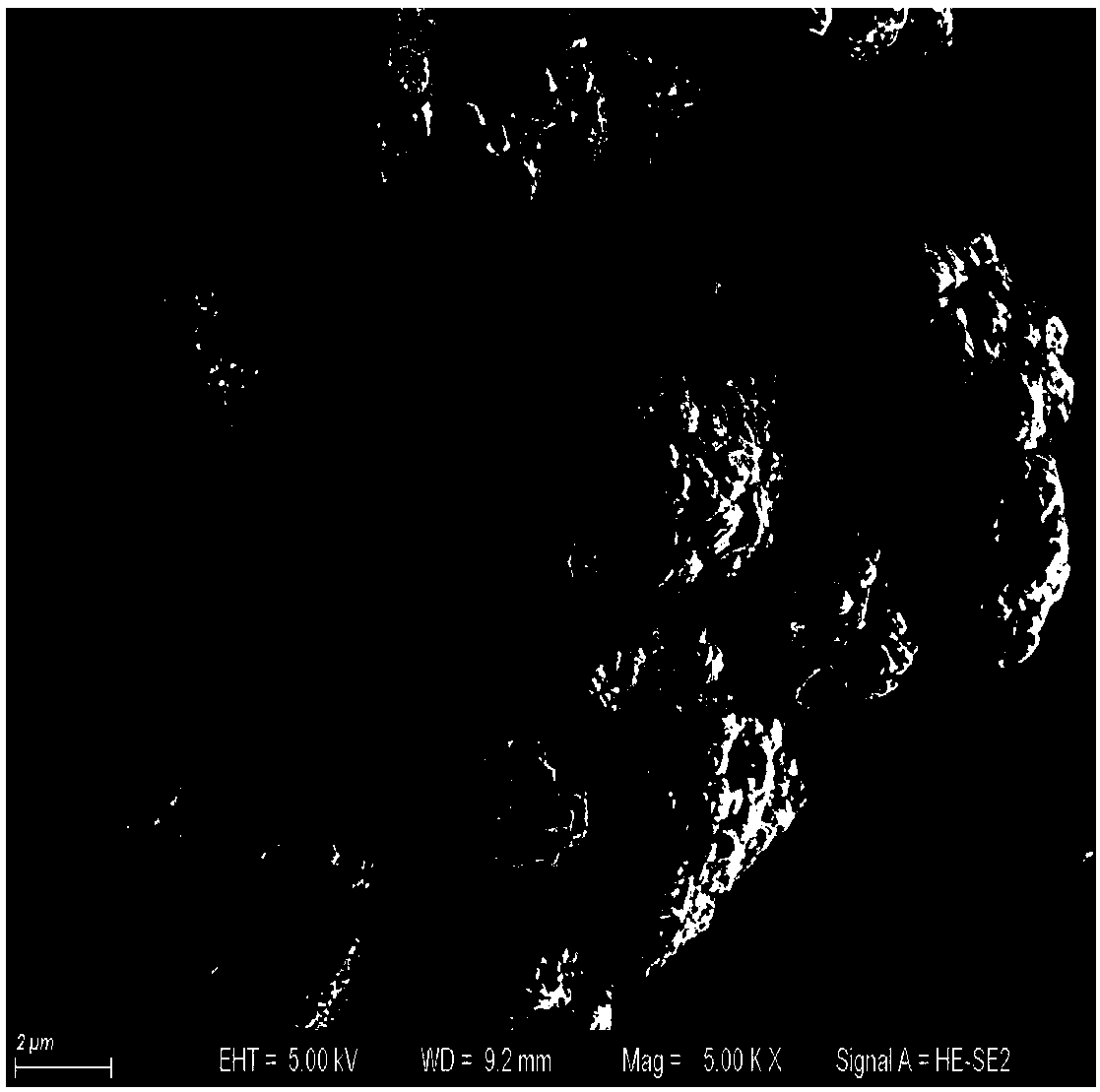

[0036] The XRD diffractometer of model D / MAX 2200PC produced by Hitachi, Japan was used for characterization, and the ...

Embodiment 2

[0038] The difference between this example and Example 1 is that the KOH concentration is 10mol / L, the hydrothermal conditions are reaction temperature 200°C, reaction time 12h, Fe(NO 3 ) 3 9H 2 O: Ni(NO 3 ) 3 ·5H 2 O=0.99:0.01.

[0039] (1) Prepare a KOH solution with a molar concentration of 10mol / L;

[0040] (2) Measure the KOH solution, then weigh the Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O, Nd(NO 3 ) 3 ·6H 2 O and Ni(NO 3 ) 2 ·6H 2 O, dissolve them in the above-mentioned KOH solution, stir for 1 h after ultrasonication for 10 min to obtain a uniform suspension;

[0041] (3) Control the temperature of the suspension obtained in step (2) to 200° C. for hydrothermal reaction for 12 hours, and then naturally cool to room temperature to obtain a reaction solution;

[0042] (4) Ultrasonic wash the reaction solution obtained in step (3) with deionized water, let it stand until the upper and lower layers are clearly separated, pour off the supernatant, and dry t...

Embodiment 3

[0045] The difference between this example and Example 1 is that the raw materials are weighed at a molar ratio of Bi:Nd:Fe:Ni=0.95:0.05:0.925:0.075.

[0046] (1) Prepare a KOH solution with a molar concentration of 7mol / L;

[0047] (2) Measure the KOH solution, then weigh the Bi(NO 3 ) 3 ·5H 2 O, Fe(NO 3 ) 3 9H 2 O, Nd(NO 3 ) 3 ·6H 2 O and Ni(NO 3 ) 2 ·6H 2 O, dissolve them in the above-mentioned KOH solution, stir for 1 h after ultrasonication for 10 min to obtain a uniform suspension;

[0048] (3) Control the temperature of the suspension obtained in step (2) to 190° C. for hydrothermal reaction for 10 h, and then naturally cool to room temperature to obtain a reaction solution;

[0049] (4) Ultrasonic wash the reaction solution obtained in step (3) with deionized water, let it stand until the upper and lower layers are clearly separated, pour off the supernatant, and dry the resulting precipitate at a temperature of 60°C to obtain neodymium and nickel co-doped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com