Method for seeking quality control index of raw material corn steep liquor for fermentation

A technology for controlling indicators and corn steep liquor, which is applied in the direction of measuring devices, material separation, and analysis of materials, etc., can solve the problems of inability to judge the quality of raw materials scientifically and accurately, and achieve good reproducibility and stability, high resolution and sensitivity, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

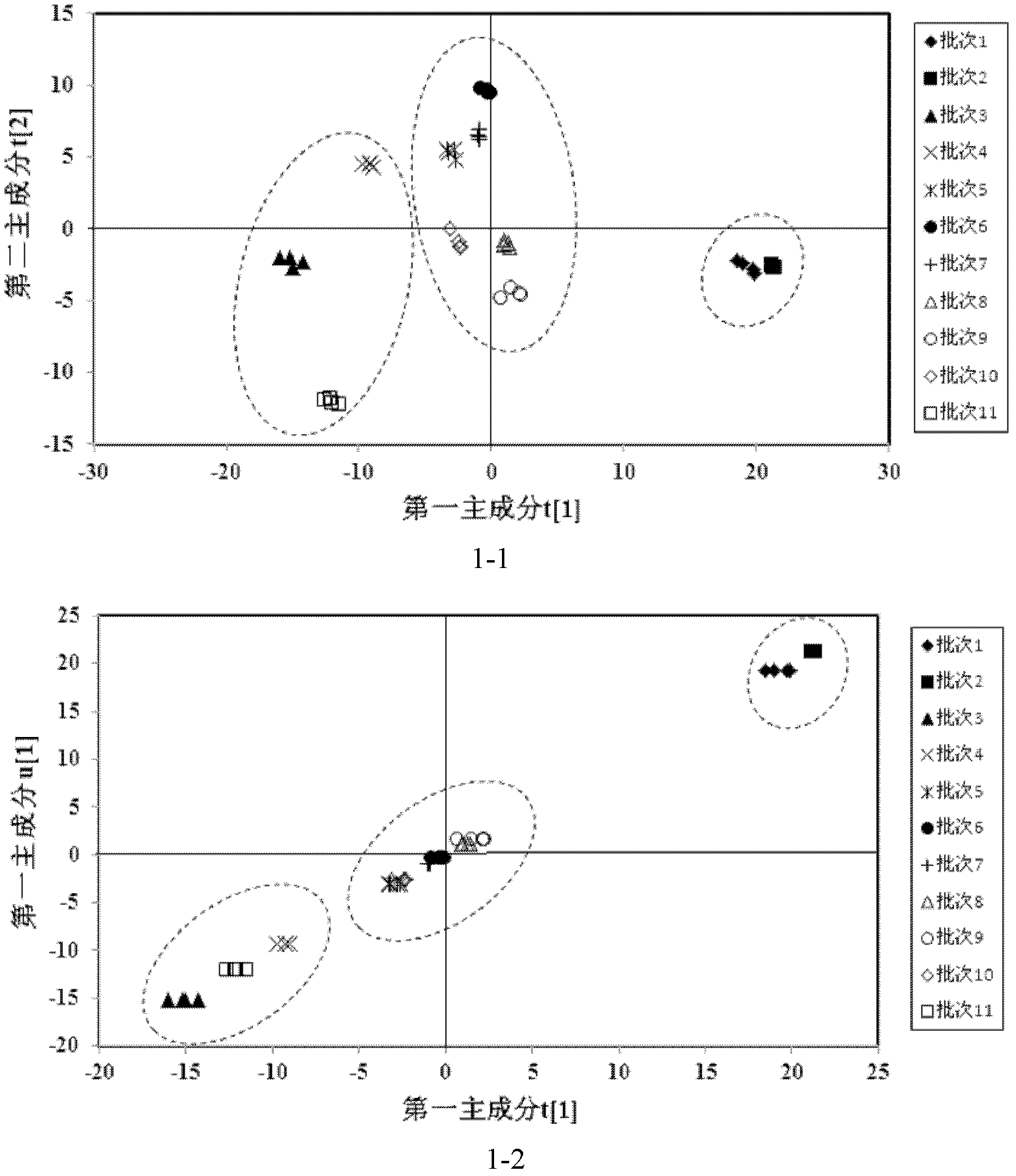

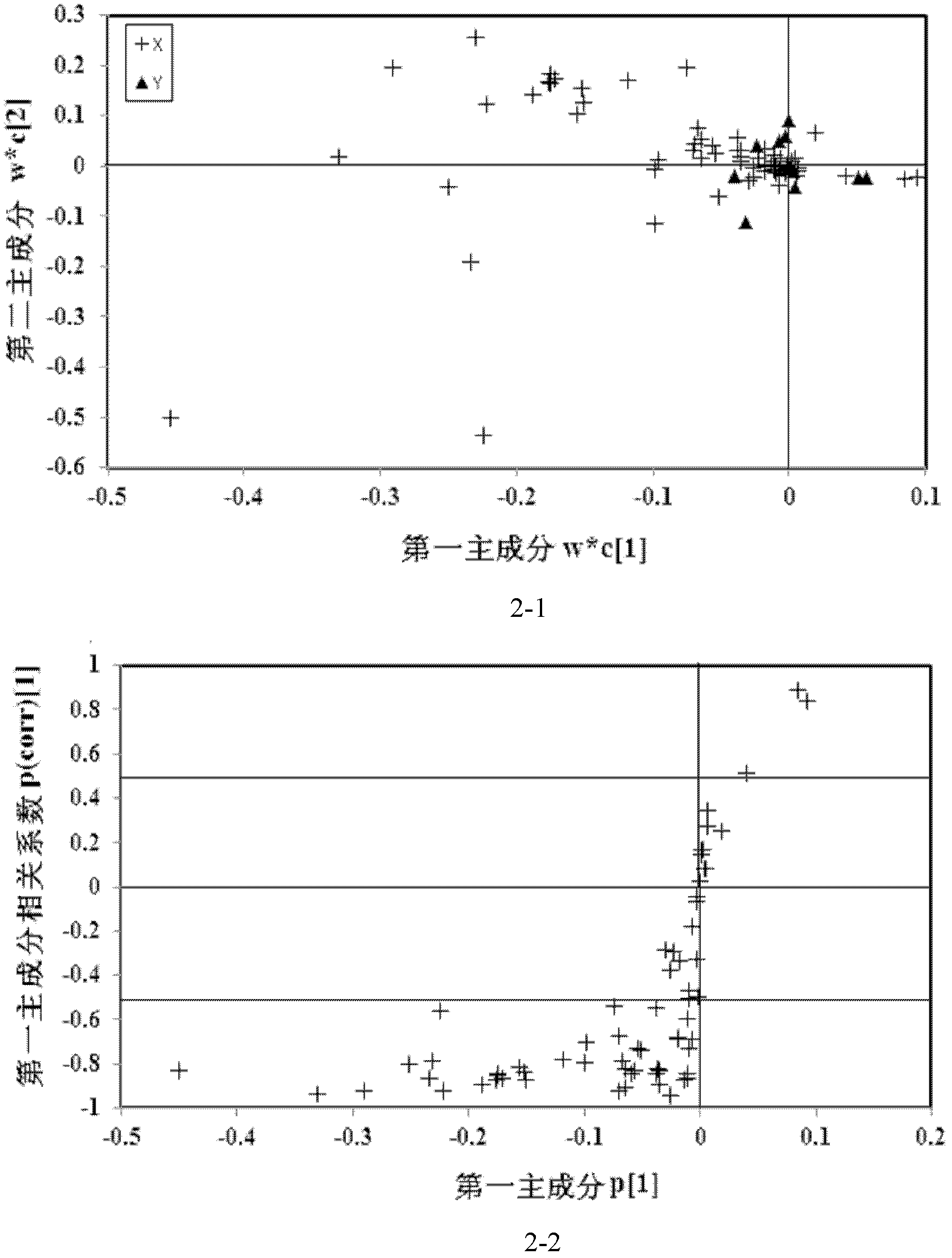

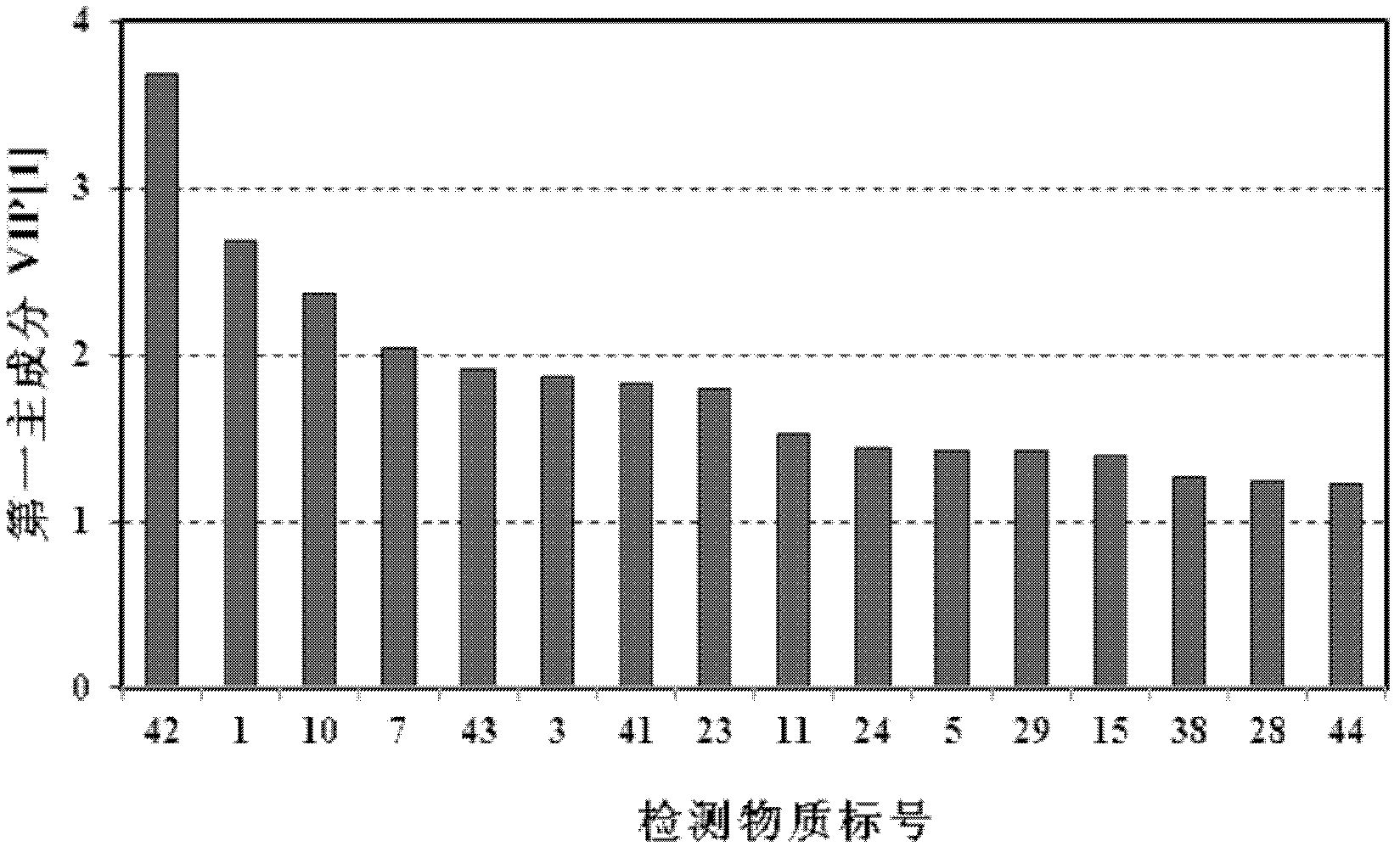

[0022] The method for seeking the quality control index of raw material corn steep liquor for fermentation comprises the following steps:

[0023] (1) Carry out chemical composition determination to 11 batches of different corn steep liquors:

[0024] ① Preparation of samples:

[0025] Put 1 g of uniform corn steep liquor sample in a centrifuge tube, centrifuge to collect the supernatant; dilute the obtained supernatant 20 times with ultrapure water, take 20 μL and put it in another centrifuge tube, add 30 μL of 0.040 mg / mL deuterium Marked methanolic succinic acid was used as internal standard. After freeze-drying, 50 μL of pyridine with a concentration of 20 mg / mL methoxyamine hydrochloride was added and dissolved in a 30° C. water bath for oximation reaction for 90 minutes. After the reaction was completed, 80 μL of N-methyl-N-trimethylsilane trifluoroacetamide was added and the silanization reaction was carried out in a water bath at 37°C for 30 minutes;

[0026] ②Gas c...

Embodiment 2

[0036] The method for seeking the quality control index of raw material corn steep liquor for fermentation comprises the following steps:

[0037] (1) Carry out chemical composition determination to 11 batches of different corn steep liquors:

[0038] ① Preparation of samples:

[0039] Put 2 g of uniform corn steep liquor sample in a centrifuge tube, centrifuge to collect the supernatant; dilute the obtained supernatant 40 times with ultrapure water, take 20 μL and put it in another centrifuge tube, add 40 μL of 0.040 mg / mL deuterium Marked methanolic succinic acid was used as internal standard. After lyophilization, 50 μL of 20 mg / mL methoxyamine hydrochloride in pyridine was added and dissolved in a water bath at 35° C. for oximation reaction for 120 min. After the reaction, add 70 μL of N-methyl-N-trimethylsilane trifluoroacetamide in a water bath at 35°C for silylation for 50 minutes;

[0040] ②Gas chromatography-time-of-flight mass spectrometer determination method:

...

Embodiment 3

[0047] The method for seeking the quality control index of raw material corn steep liquor for fermentation comprises the following steps:

[0048] (1) Carry out chemical composition determination to 11 batches of different corn steep liquors:

[0049] ① Preparation of samples:

[0050] Put 0.5 g uniform corn steep liquor sample in a centrifuge tube, centrifuge to collect the supernatant; dilute the obtained supernatant 20 times with ultrapure water, take 40 μL and put it in another centrifuge tube, add 30 μL of 0.040 mg / mL Deuterium-labeled succinic acid in methanol was used as the internal standard. After lyophilization, 70 μL of pyridine with a concentration of 20 mg / mL methoxyamine hydrochloride was added and dissolved in a water bath at 37° C. for oximation reaction for 60 min. After the reaction, add 100 μL of N-methyl-N-trimethylsilane trifluoroacetamide in a water bath at 40°C for silanization for 20 minutes;

[0051] ②Gas chromatography-time-of-flight mass spectrome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com