Weeding composition

A herbicidal composition and composition technology, applied in the direction of herbicides, algicides, biocides, animal repellents, etc., to achieve the effects of expanding the weeding spectrum, improving the control effect, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 (10% oxadifen·Penoxsulam·Pyrimsulfuron oil suspension concentrate).

[0033] Oxfentrazone 6%, Penoxsulam 2%, Pyrimsulfuron 2%, Phenol polyoxyethylene ether 5%, Sodium lignosulfonate 8%, Epoxy soybean oil 5%, Organic bentonite 5%, the rest is refined soybean oil and add to 100%.

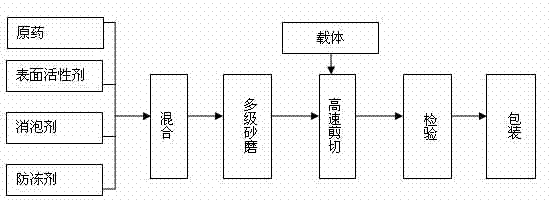

[0034] Add the above-mentioned materials (except organic bentonite) to the reactor mixer, stir for 2 hours, open the feed valve at the bottom of the kettle, and inject the materials into the multi-stage sand mill for grinding. The fineness of the ground materials is 98% through 1- After 5um, the material is discharged, and the material is put into the high-shear emulsification kettle together with the organic bentonite dissolved in advance. After emulsification, it can be made into 10% oxadifen·Penoxsulam·pyrimethamine with good flowability. Susulfuron oil suspension agent. See the specific process figure 1 .

[0035] This example is used to control annual weeds in direct-seeded rice fie...

Embodiment 2

[0038] Example 2 (45% oxfentrazone·Penoxsulam·Pyrimsulfuron-methyl water dispersible granules).

[0039] Oxfentrazone 30%, Penoxsulam 8%, Pyrimsulfuron 7%, Sodium Lauryl Sulfate 4%, Polycarboxylic Acids 5%, Urea 40%, and the rest is kaolin to 100% .

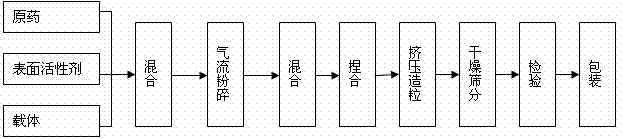

[0040] Add the above-mentioned materials to the cone mixer and mix them evenly, and then pulverize by the jet mill. The pulverized materials are then mixed by the cone mixer. The fineness of the mixed material is 98% through the 325 mesh standard sieve and added to the kneader. Kneaded into plastic materials, and finally put the materials into an extrusion granulator to extrude and granulate. After granulation, they were dried and sieved to obtain 45% oxadifen·Penoxsulam·Pyramsulfuron Long water dispersible granules. See the specific process figure 2 .

[0041] This example is used to control annual weeds in rice seedling throwing fields: the experiment was carried out in rice throwing seedling fields with more cedar, barnyardgrass...

Embodiment 3

[0044] Example 3 (25% oxfentrazone, penoxsulam, pyrazosulfuron-methyl wettable powder).

[0045] Oxfentrazone 16%, Penoxsulam 5%, Pyrimsulfuron 4%, Sodium Lauryl Sulfate 2%,

[0046] Sodium butyl naphthalene sulfonate 3%, calcium lignosulfonate 5%, white carbon black 5%, and the rest is kaolin to 100%.

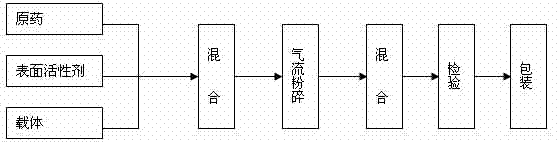

[0047] Add the above materials to the cone mixer and mix them evenly, and then pulverize by the jet mill. The pulverized materials are then mixed by the cone mixer. The fineness of the mixed materials is 98% and passes through the 325 mesh standard sieve, which is 25%. Oxfentrazone, Penoxsulam, Pyrimsulfuron-methyl WP. See the specific process image 3 .

[0048] This example is used to control annual weeds in rice seedling throwing fields: the experiment was carried out on rice transplanting fields with more cedar, barnyardgrass and broadleaf weeds. There were 5 treatments in the experiment, and treatment 1 was 25% oxazole grass. Amine·Penoxsulam·Pyrimsulfuron-methyl wettable powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com