Preparation method of dynamic magnet-coated nano-sized solid-phase open-tubular capillary electric chromatography column

A technology of capillary electrochromatography and stationary phase, which is applied in the field of preparation of dynamic magnetic coating nanometer stationary phase open-tube capillary electrochromatography column, can solve the problems of low column capacity, small column capacity, difficult regeneration, etc. Improved column capacity and smaller nanoparticle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a dynamic magnetically coated nanometer stationary phase open-tube capillary electrochromatographic column, the specific steps of which are as follows:

[0035] 1. Functionalization of magnetic nanomaterials:

[0036] core-shell Fe 3 o 4 SiO 2 Magnetic nanomaterials react with silylating reagents to introduce specific functional groups on their surface to prepare the stationary phase required for sample separation;

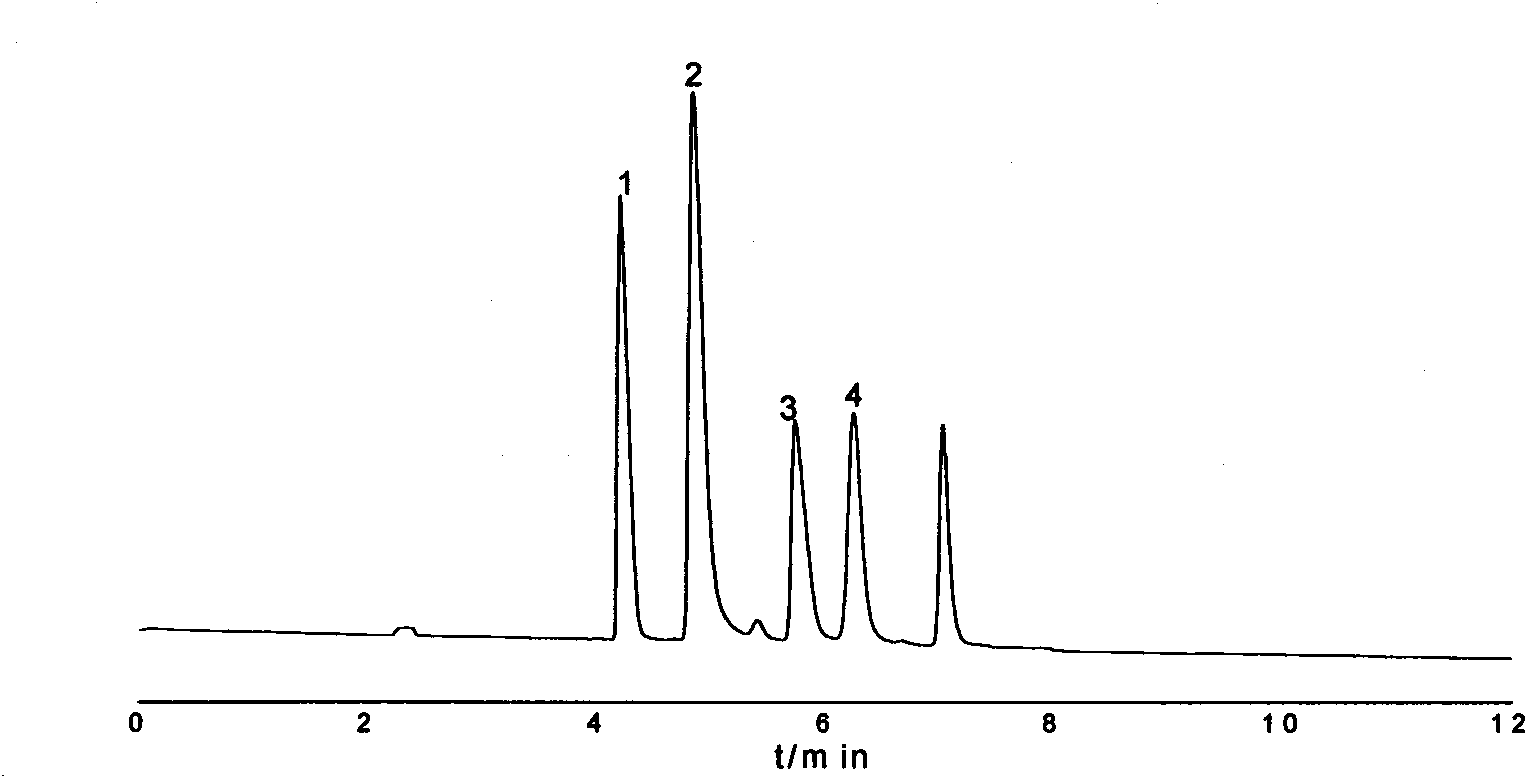

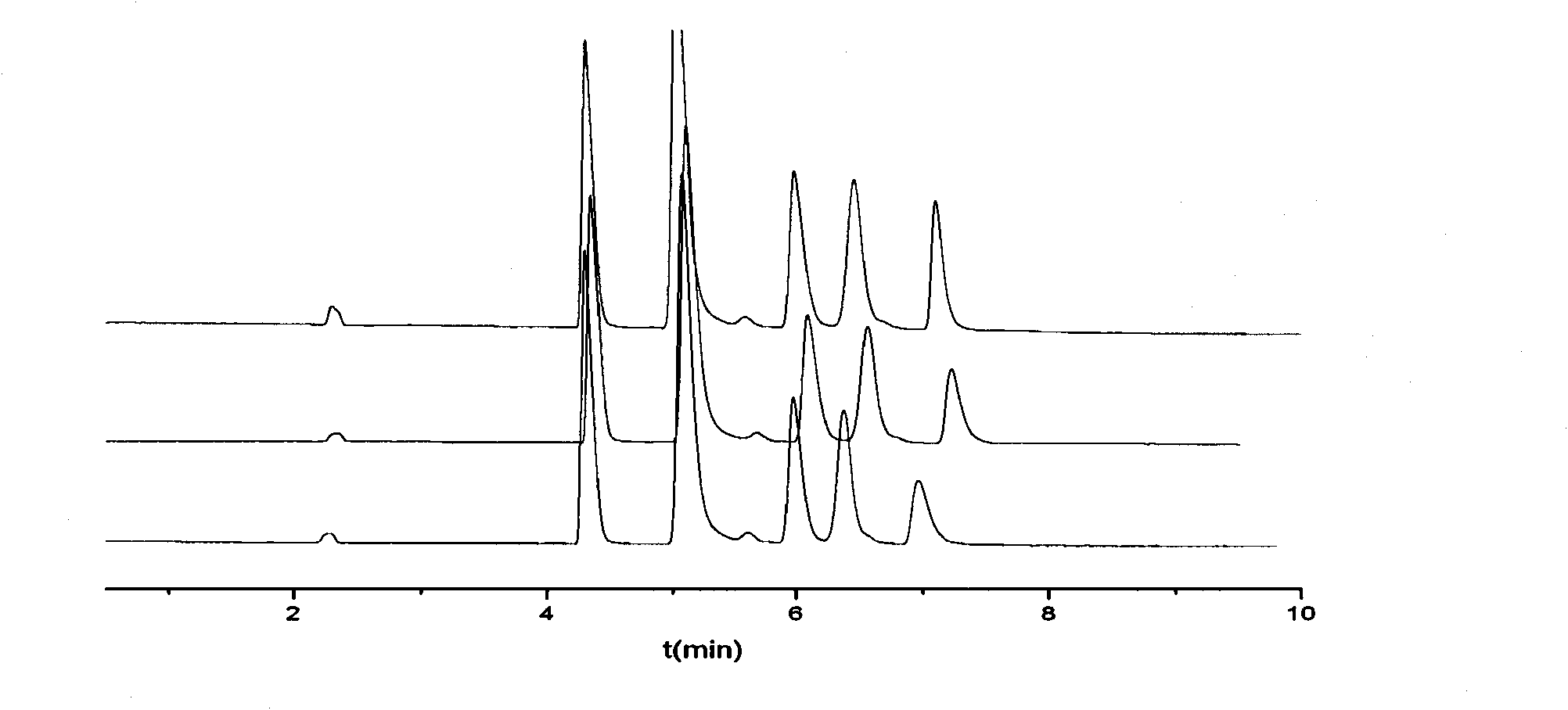

[0037] 2. Preparation of dynamic magnetically coated nano-stationary phase open-tube capillary electrochromatographic column:

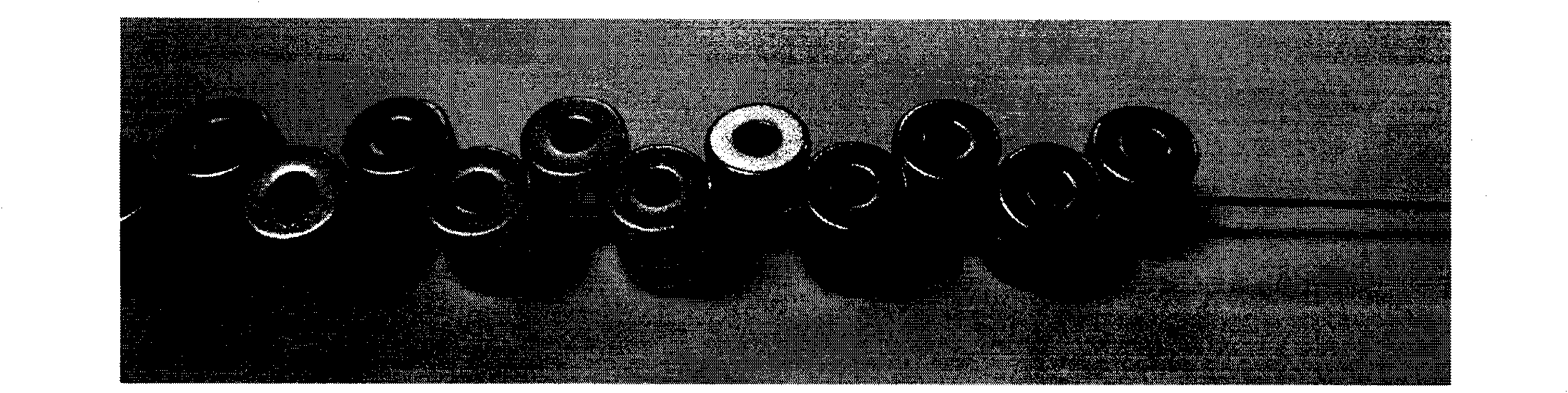

[0038] (1) Selection of permanent magnets

[0039] Permanent magnets are used to provide a stable magnetic field;

[0040] The permanent magnets are cuboids, cubes, cylinders, concentric cylinder magnets, etc.;

[0041] (2) Selection of magnetic field direction

[0042] Clamp 23~50 pairs of permanent magnets as described in (1) on the capillary to provide a locally stable magnetic field in the directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com