Polyanion composite material, its preparation method and application

A composite material, polyanion technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of low electronic and ionic conductivity, cannot improve the rate performance and cycle performance of materials at the same time, and improve the electronic conductivity. efficiency, improve interface stability, and achieve the effect of simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

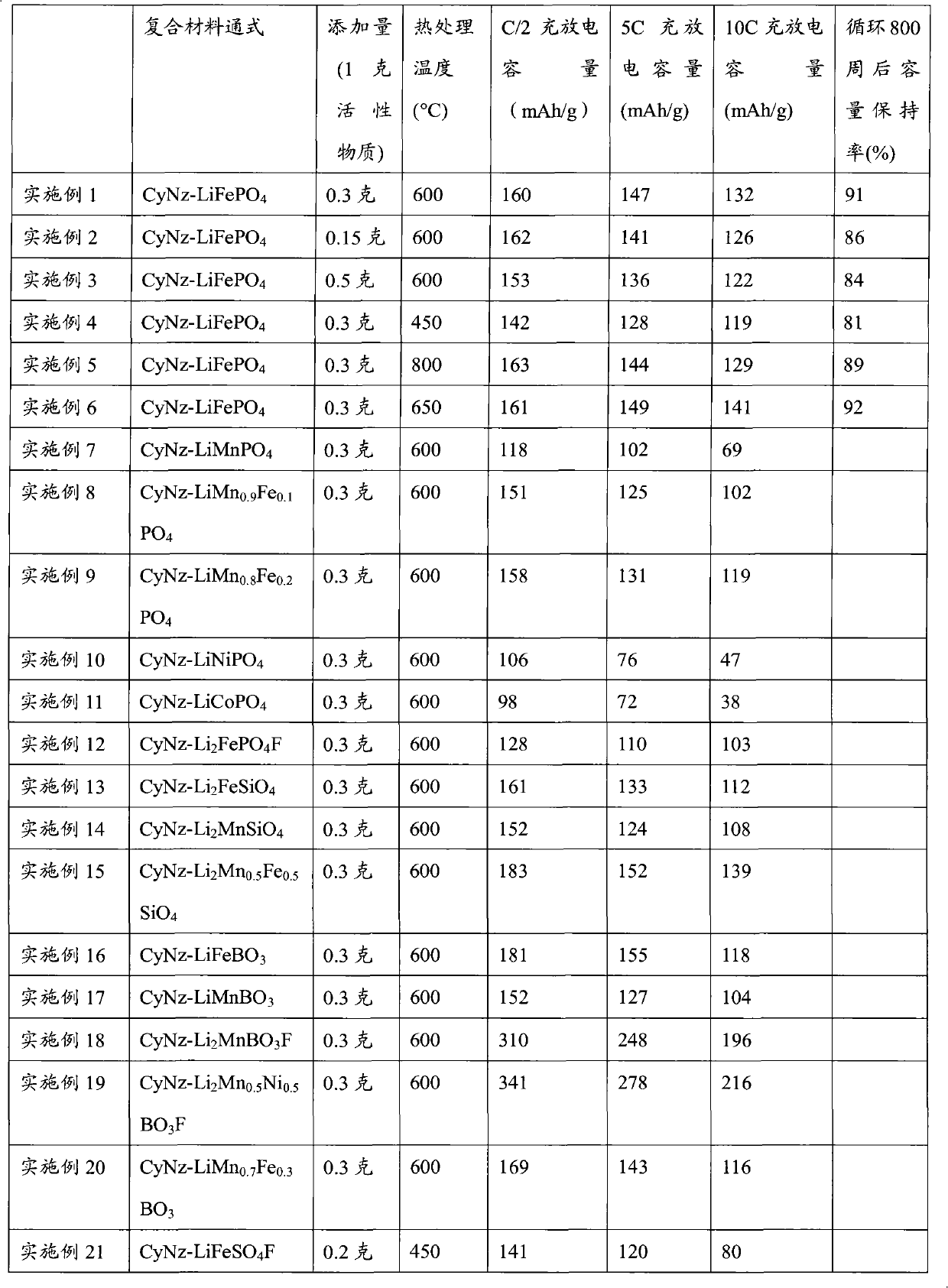

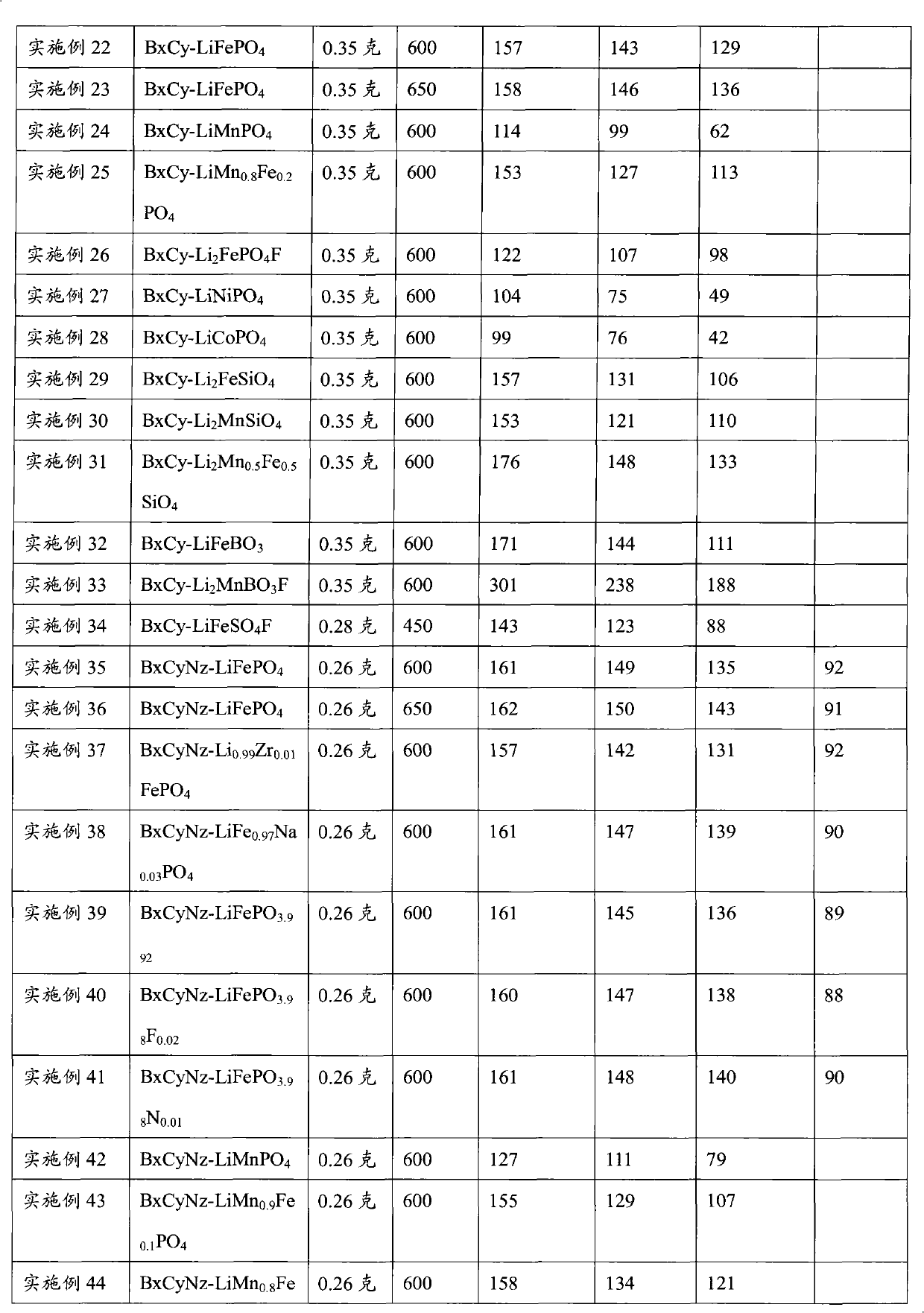

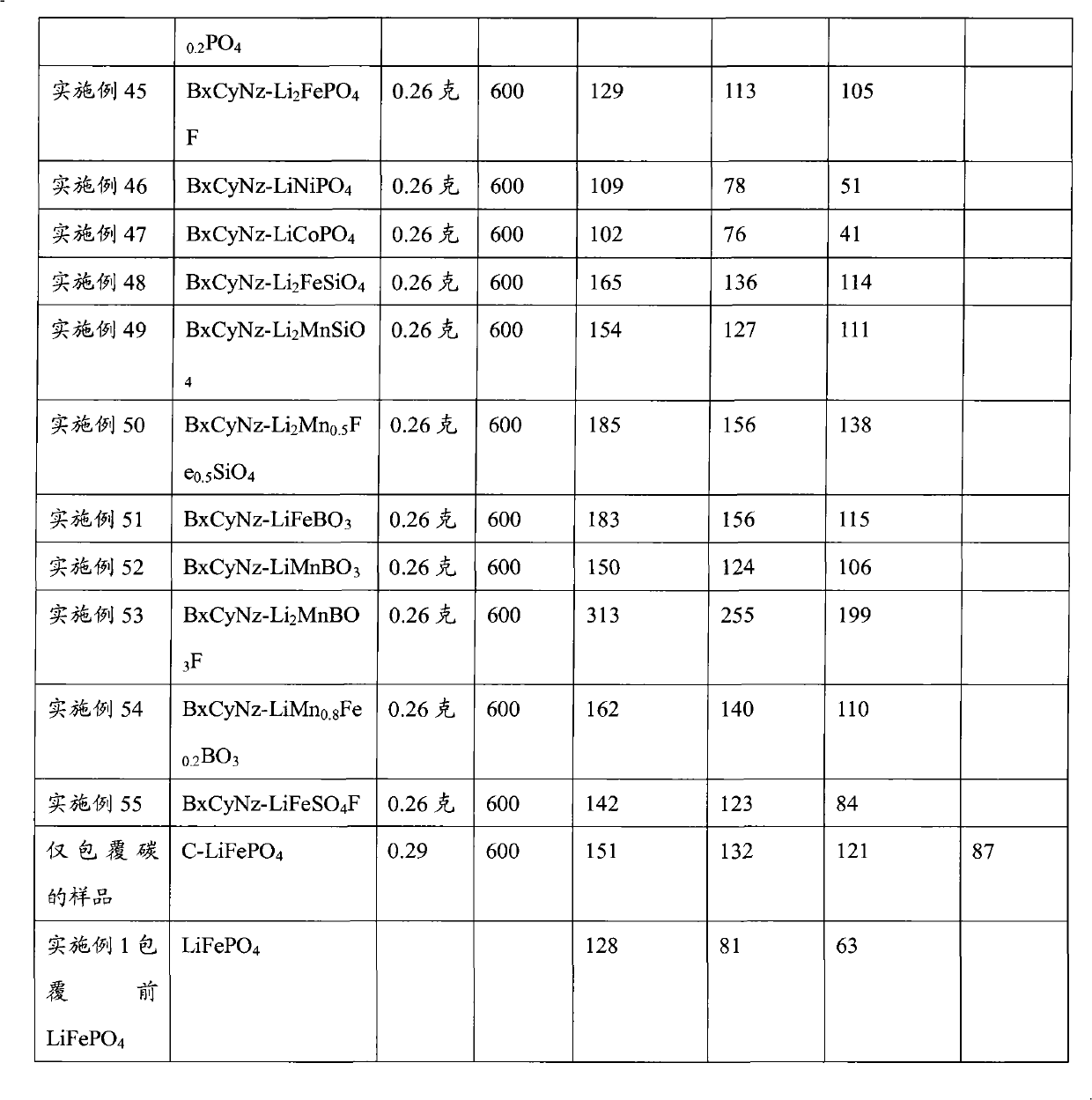

[0083] In a dry atmosphere, the carbon-nitrogen-containing ionic liquid [EMIm][N(CN) 2 ]0.3g add 1gLiFePO 4 powder and shake in a shaker mixer for 30 minutes to obtain a gritty mixture. Transfer this mixture to an alumina crucible and place in a tube furnace with argon or nitrogen. Raise the temperature from room temperature to 600°C at a rate of 2°C / min, and keep at 600°C for 2 hours to fully crack the ionic liquid. After the tube furnace cools down, take out the sample and grind it into a black powder, which is the composite material of the present invention. Wherein, the weight percent content of nitrogen in the carbonitride compound is about 28%, and the weight percent content of the carbonitride compound in the composite material is about 5%.

[0084] Make samples to simulate batteries. LiFePO before and after coating 4 : Acetylene black: PVdF binding agent=85%: 10%: 5% ratio is mixed under normal temperature and pressure to form slurry, evenly coated on the aluminum ...

Embodiment 2-3

[0086] Prepare the polyanion composite material for secondary lithium battery of the present invention that forms by the method for embodiment 1 by table 1, difference is, the content of ionic liquid and active material is not the same, obtains different carbonitride weight percents The content of composite materials is about 2% and 12%, respectively.

[0087] The assembly of the positive electrode, negative electrode, electrolyte and battery of the simulated battery is the same as in Example 1, and the test results are listed in Table 1.

Embodiment 4-5

[0089] The method for preparing by the embodiment 1 is used for the polyanion composite material of the present invention of the composition of table 1, and difference is, heat treatment temperature is not the same, obtains the weight percent content of different nitrogen in carbonitride The composite materials are about 38% and 7%, respectively.

[0090] The assembly of the positive electrode, negative electrode, electrolyte and battery of the simulated battery is the same as in Example 1, and the test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com