Pigment dispersion composition

A pigment dispersion and composition technology, applied in the directions of pigment paste, azine dyes, azo dyes, etc., can solve the problems of color filter chromaticity or dimensional accuracy decline, contrast deterioration, etc., and achieve high dispersion stability and high contrast. , the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

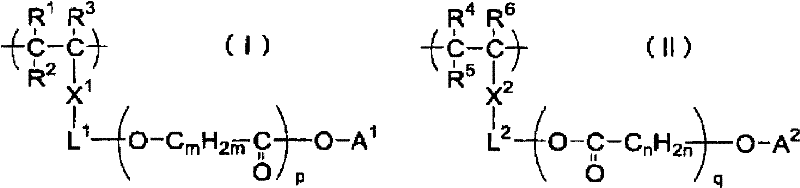

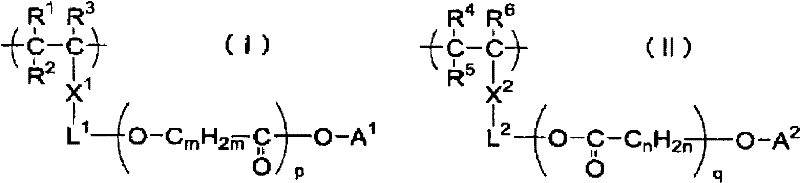

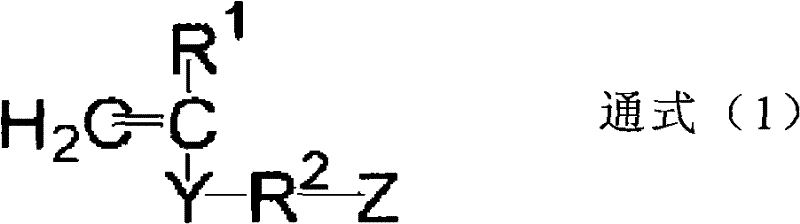

Method used

Image

Examples

Embodiment

[0348] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited thereto.

Synthetic example 1

[0350] (Synthesis of P-1 of Polymer A)

[0351] 27.0 g of the aforementioned M-6, 126.0 g of MMA, 27.0 g of MAA, and 420.0 g of 1-methoxy-2-propanol were introduced into a three-necked flask replaced with nitrogen, and were mixed with a stirrer (Shinto Scientific Co., Ltd.: three- one motor) and heated while blowing nitrogen into the flask to raise the temperature to 90°C. 1.80 g of 2,2-azobis(2,4-dimethylvaleronitrile) (V-65 manufactured by Wako Pure Chemical Industries, Ltd.) was added to the flask, followed by heating and stirring at 90° C. for 2 hours. After 2 hours, 1.80 g of V-65 was further added, and after heating and stirring for 3 hours, a 30% by mass solution of polymer P-1 was obtained. Measurement was performed by gel permeation chromatography (GPC) under the following conditions using polystyrene as a standard substance. Moreover, it titrated using sodium hydroxide, and the acid value with respect to solid content was 99 mgKOH / g. These measurement methods are ...

Synthetic example 2

[0370] (Synthesis of P-2 and P-3 of Polymer B)

[0371] Into a 500 mL three-necked flask, 160.0 g of ε-caprolactone and 18.3 g of 2-ethyl-1-hexanol were introduced, stirred and dissolved while purging with nitrogen. Add 0.1 g of monobutyltin oxide and heat to 100°C. Eight hours later, after confirming the disappearance of the raw materials by gas chromatography, it was cooled to 80°C. After adding 0.1 g of 2,6-di-t-butyl-4-methylphenol, 22.2 g of 2-methacryloyloxyethyl isocyanate was added. After 5 hours, the disappearance of the raw material was confirmed by H NMR, and then cooled to room temperature to obtain 200 g of a solid monomer (A-5). Monomer (A-5) was confirmed by H NMR, IR, and mass analysis.

[0372] The obtained monomer (A-5) is a monomer mentioned as a preferable specific example of the monomer represented by the said general formula (i), (ii) or (i)-2.

[0373] 37.5 g of monomer (A-5), 5.0 g of monomer M-11, 7.5 g of methacrylic acid, 1.3 g of dodecyl mercaptan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com