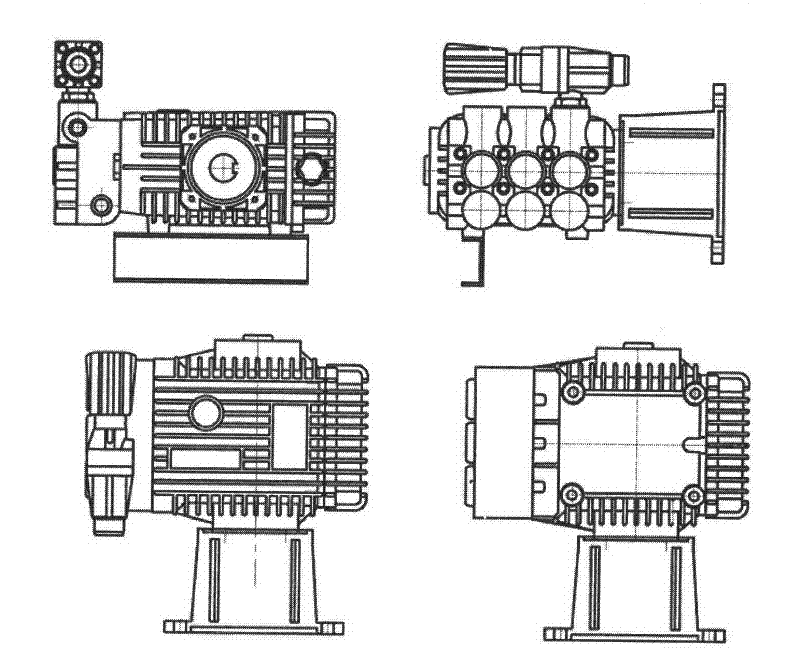

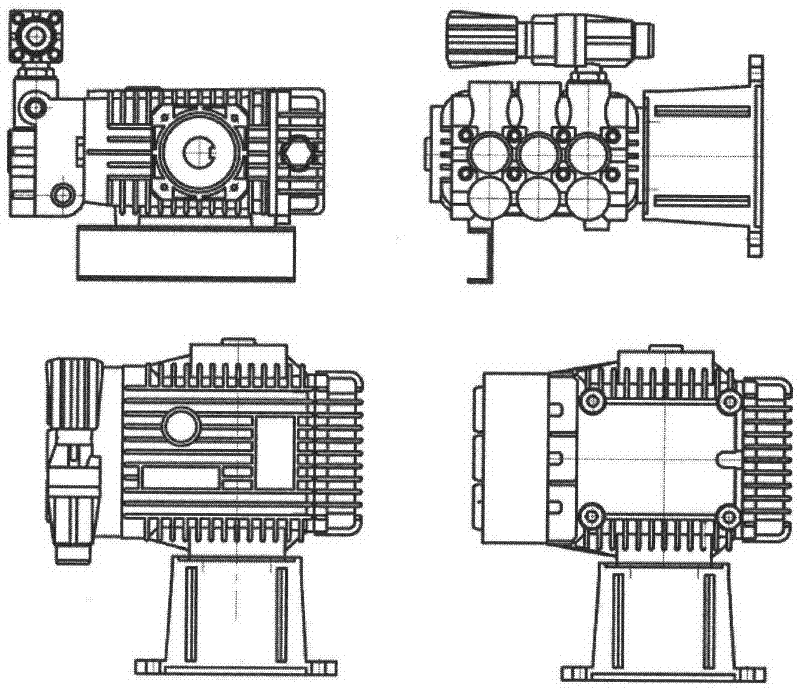

High-efficiency three-cylinder fine ceramic plunger pump

A fine ceramic, high-efficiency technology, used in pumps, pump components, variable capacity pump components, etc., can solve the problems of insufficient output flow of hydraulic pumps, fluctuations in output flow, abnormal output pressure, etc., to achieve light weight, reliable operation, Good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In the following detailed description, specific details are described in order to provide a thorough understanding of the present invention. Those skilled in the art will recognize, however, that the invention may be practiced with other similar details.

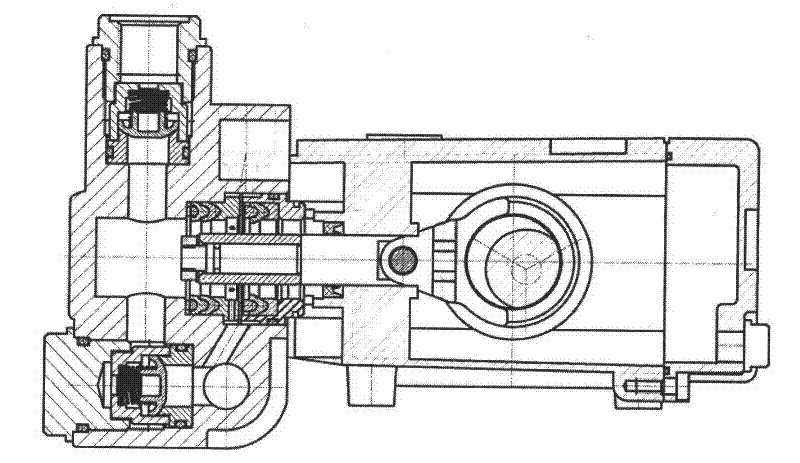

[0016] The high-efficiency three-cylinder fine ceramic plunger pump converts mechanical energy into water flow pressure energy. The power passes through the crank connecting rod mechanism to convert the rotational motion of the crankshaft into the reciprocating motion of the plunger. When the plunger retreats, due to the vacuum suction, the water enters When the valve is opened and the outlet valve is closed, water is sucked into the tank; when the plunger advances, the water inlet valve is closed, the outlet valve is opened, and the high-pressure water is discharged from the outlet valve through the high-pressure pipe due to the increase of the water pressure in the pump. The rotary motion is converted into the linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com