Processing method of charbroiled dried meat slices

A processing method and technology of jerky, applied in the field of processing barbecue meat products, can solve the problems of poor food hygiene and food safety, complex formula, high requirements, etc., and achieve industrial scale production, high degree of mechanized operation, and improved The effect of tissue softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

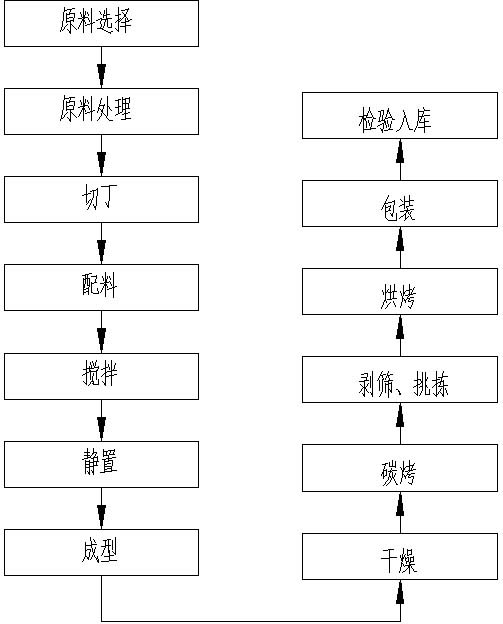

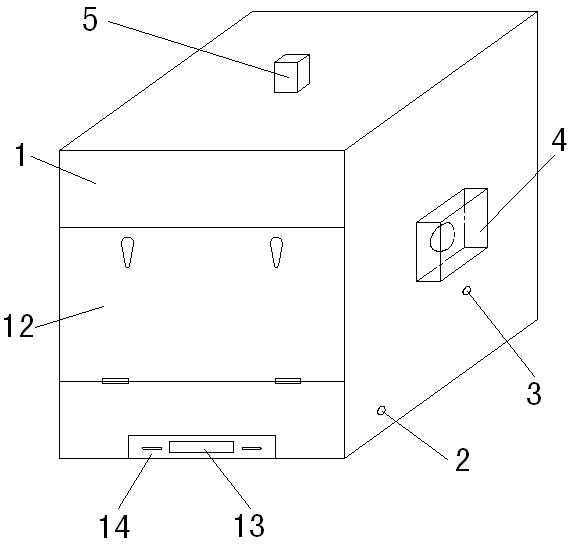

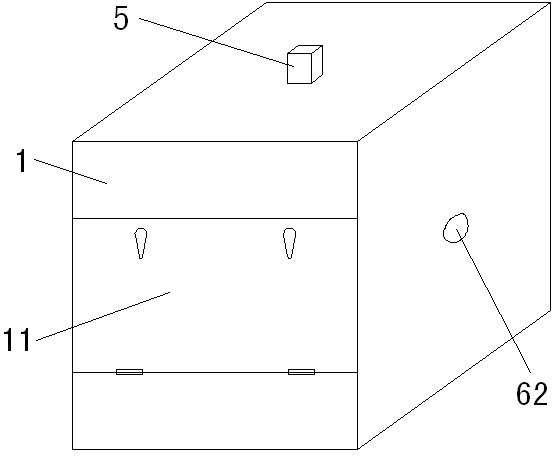

[0042] see Figure 1 to Figure 6 The raw materials used in the processing method of charcoal-grilled jerky in this embodiment include raw meat, sugar, fish sauce, white pepper, soy sauce and licorice powder. The weight ratio of fat is 94:(5-8), preferably 94:6, and the weight ratio of raw meat, sugar, fish sauce, white pepper, light soy sauce and licorice powder is 100:(25-35):( 6-10):(0.08-0.12):(1.5-2.5):(0.03-0.08), preferably 100:30:8:0.1:2:0.05.

[0043] In this embodiment, pre-cooled fresh pork hind legs and spine fat are selected as raw meat, and the hind legs have no congestion, lymph, broken bones and bad smell; the spine fat has no pig skin and bruises. To process the raw meat, first put the raw meat into flowing water to clean the pig hair and other impurities on the surface of the meat, and put the cleaned raw meat into the turnover basket to drain the water. Following the lean meat texture of the pig, cut off blood congestion, broken bones, tendons, fascia and f...

Embodiment 2

[0063] see Figure 1 to Figure 6 , the present invention also can make beef jerky, and technology is specifically as follows.

[0064] 1. Raw material selection.

[0065] Raw materials include raw meat, sugar, fish sauce, white pepper, oyster sauce, light soy sauce and licorice powder. Among them, lean beef and butter are used as raw meat, and lean beef:butter=9:1, raw meat, sugar, The weight ratios of fish sauce, white pepper, oyster sauce, light soy sauce and licorice powder are 100:30:10:0.1:0.2:2:0.05, respectively.

[0066] The beef lean meat is frozen beef hind legs that have undergone deacidification, and the butter is the belly fat of the beef. It is required that the butter has no congestion, lymph, bone fragments and bad smell.

[0067] 2. Raw material processing.

[0068] Follow the texture of the beef, cut off the tendons and large pieces of fat, and cut the meat into natural pieces. Tear off the oil film on the surface of the butter, repair the residual blood ...

Embodiment 3

[0098] see Figure 1 to Figure 6 , the present invention also can make dried chicken, and technology is specifically as follows.

[0099] 1. Raw material selection.

[0100] Raw materials include raw meat, sugar, fish sauce, white pepper, light soy sauce and licorice powder. Among them, skinless chicken breast and skinned chicken thigh are used as raw meat, and chicken thigh: chicken breast=3:2, raw meat, sugar The weight ratios of fish sauce, white pepper, soy sauce and licorice powder are 100:28:7.5:0.1:2:0.05, respectively.

[0101] Choose frozen skinless chicken breasts and skinned chicken legs; the color of skinless chicken breasts is light yellow or milky white, and the muscles are elastic. Bad smell. Thawing water loss rate ≤ 6%.

[0102] 2. Raw material processing.

[0103] Rinse the chicken breast and leg meat in clean water once, put them into a perforated turnover basket to drain the water, trim the chicken leg meat piece by piece to remove impurities such as i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com