Method for preparing hydrophobic Cr-Ce-based catalyst through ultrasound-hydrogen reduction

A hydrophobicity and catalyst technology, applied in the field of catalytic chemistry, can solve the problems of increasing operating costs, decreasing the activity of catalysts for catalytic oxidation of CVOCs, and reducing the content of surface active species, achieving high catalytic activity, good practical application prospects, and strong hydrophobicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

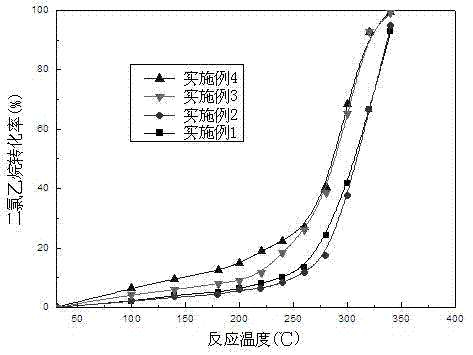

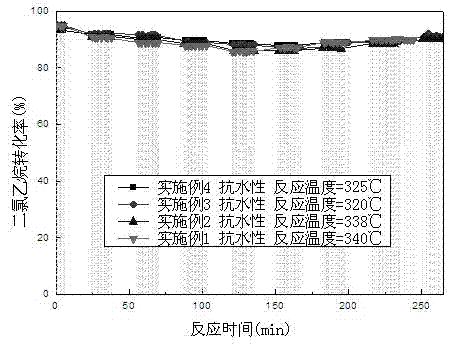

Embodiment 1

[0028] 1.9207g Cr(NO 3 ) 3 ·9H 2 O and 0.5211g Ce(NO 3 ) 3 ·6H 2 O was dissolved together in 10mL deionized water to prepare Cr(NO 3 ) 3 And Ce(NO 3 ) 3 Mixed solution; add 0.05g 60 mesh Al to the mixed solution 2 O 3 The particles were oscillated at a constant temperature of 50°C and immersed in 300W ultrasonic for 5 minutes, dried at 120°C for 12 hours, and calcined at 550°C for 5 hours to obtain solid particles. min's H 2 Purge for 60 minutes. The solid particles after the reduction treatment were then placed in the air and calcined at 350°C for 60 minutes to prepare a hydrophobic Cr-Ce-based catalyst.

Embodiment 2

[0030] 2.881g Cr(NO 3 ) 3 ·9H 2 O and 0.7816g Ce(NO 3 ) 3 ·6H 2 O was dissolved together in 10mL deionized water to prepare Cr(NO 3 ) 3 And Ce(NO 3 ) 3 Mixed solution; add 0.05g 80 mesh Al to the mixed solution 2 O 3 The particles were oscillated at a constant temperature of 30°C and immersed in 250W ultrasonic for 20 minutes, dried at 120°C for 12 hours, and calcined at 550°C for 5 hours to obtain solid particles; the solid particles were placed in a fixed bed, the bed was heated to 350°C, and the volume flow rate was 30mL / min's H 2 Purge for 50 min. The solid particles after the reduction treatment were then placed in the air and calcined at 350°C for 60 minutes to prepare a hydrophobic Cr-Ce-based catalyst.

Embodiment 3

[0032] 3.841g Cr(NO 3 ) 3 ·9H 2 O and 1.0422g Ce(NO 3 ) 3 ·6H 2 O was dissolved together in 10mL deionized water to prepare Cr(NO 3 ) 3 And Ce(NO 3 ) 3 Mixed solution; add 0.05g 80 mesh Al to the mixed solution 2 O 3 The particles were oscillated at a constant temperature of 40°C and immersed in 150W ultrasonic for 40 minutes, dried at 120°C for 12 hours, and calcined at 550°C for 5 hours to obtain solid particles; the solid particles were placed in a fixed bed, the bed was heated to 350°C, and the volume flow rate was 40mL / min's H 2 Purge for 30 minutes. The solid particles after the reduction treatment were then placed in the air and calcined at 350°C for 60 minutes to prepare a hydrophobic Cr-Ce-based catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com