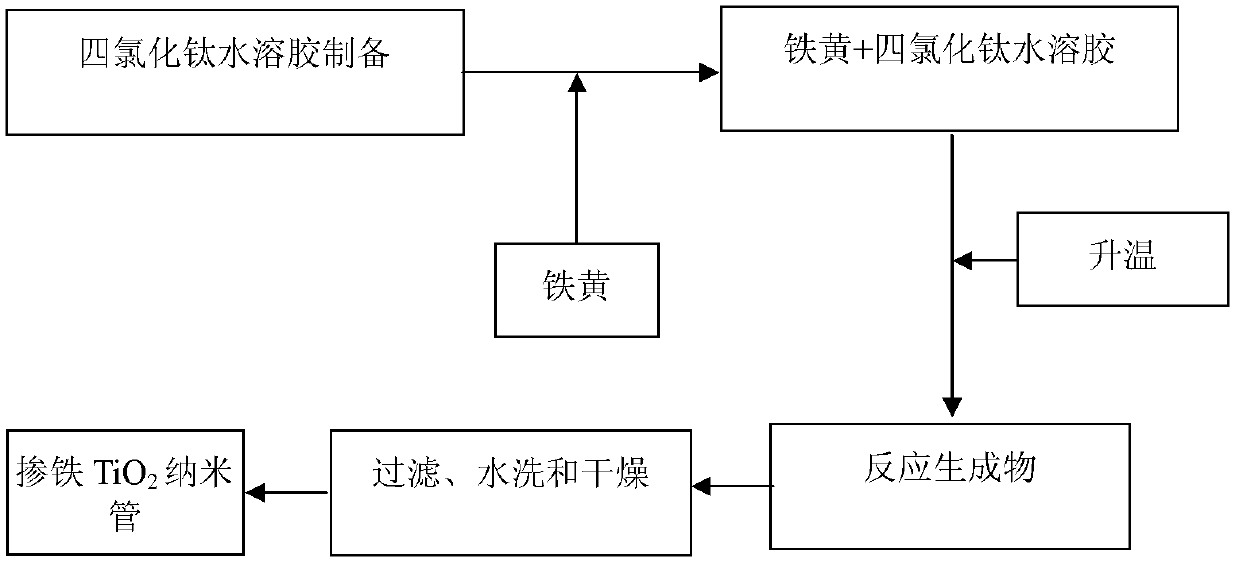

Preparation method of iron-doped TiO2 nanotube

A technology of nanotubes and iron yellow, which is applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc., to achieve the effect of low equipment requirements, superior performance, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

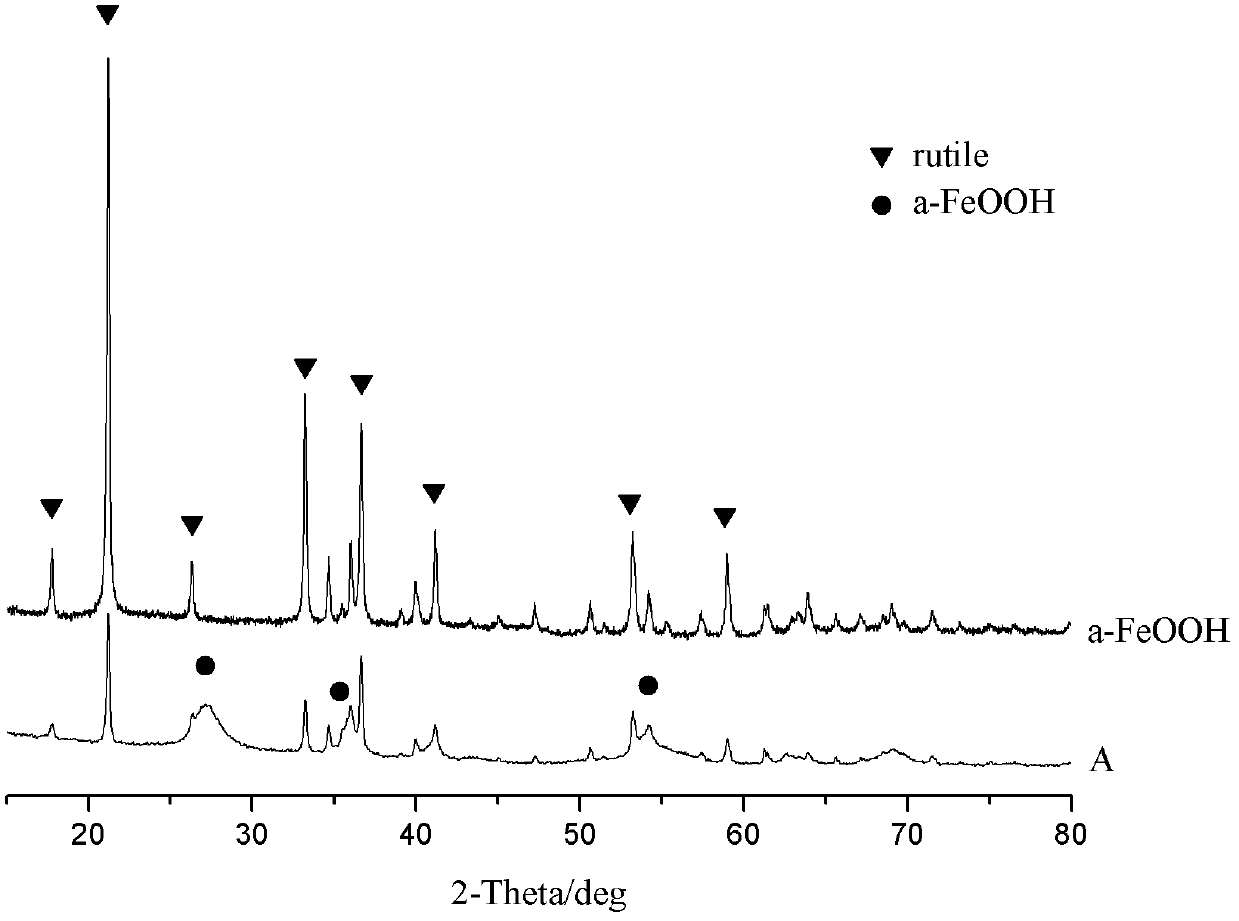

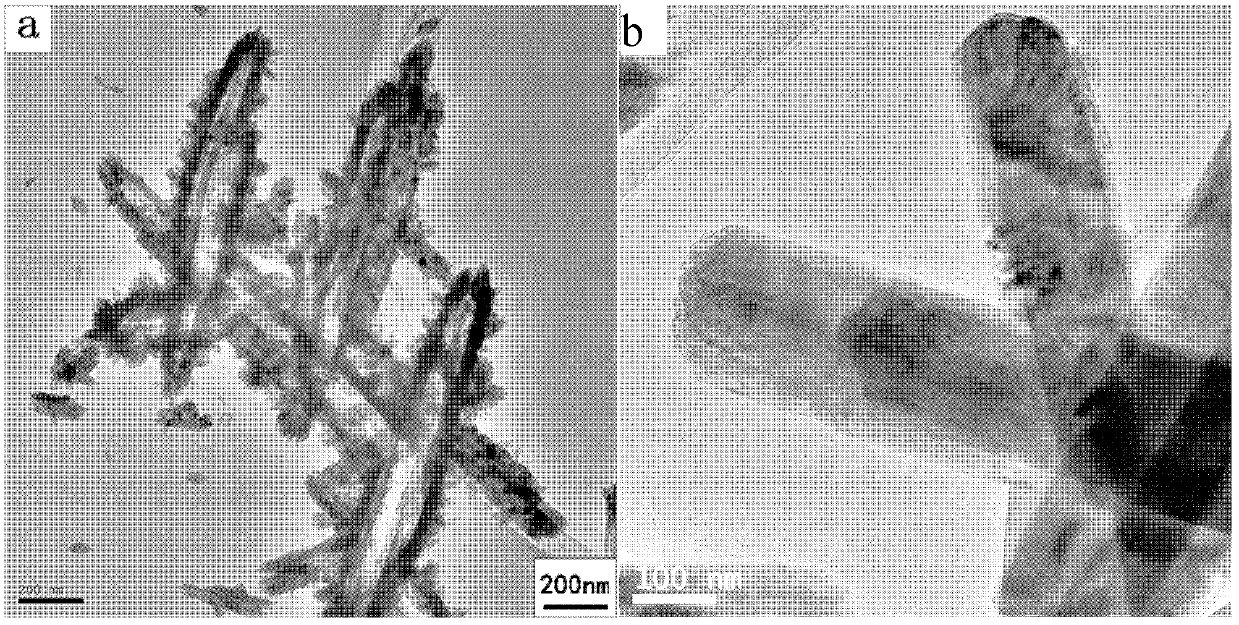

Examples

Embodiment 1

[0041] (1) Fix a 500mL three-necked bottle in an ice water bath, and take distilled water (H 2 O) 200mL into a three-necked flask; install a condenser on the middle mouth of the three-necked flask and use tap water to condense; install a thermometer on one mouth of the three-necked flask to monitor and control the temperature of the reaction system; take TiCl 4 Put 100mL into a dry constant pressure separatory funnel, install the constant pressure separatory funnel on the other side of the three-necked flask; under the conditions of magnetic stirring and ice-water bath cooling, turn on the switch of the constant pressure separatory funnel, Titanium chloride was slowly dropped into distilled water, and the temperature of the entire dropping and mixing process was controlled at about 0℃ by controlling the dropping rate and the temperature of the ice water bath; with the addition of titanium tetrachloride, the color of the system gradually changed, from nothing The color transparent...

Embodiment 2

[0046] (1) Using the equipment described in step (1) in Example 1, take distilled water (H 2 O) 200mL into a three-necked bottle; take TiCl 4 100mL into a dry constant pressure separatory funnel; under the conditions of magnetic stirring and ice-water bath cooling, turn on the switch of the constant pressure separatory funnel, slowly drip the titanium tetrachloride solution into pure water, and control the dropping speed and The temperature of the ice-water bath makes the temperature of the entire dripping and mixing process controlled at about 0℃; after the titanium tetrachloride dripping is completed, continue to stir for 2 hours. At this time, the mixed system is a light yellow-green sol. Cool it to room temperature and place it. ;

[0047] (2) Using the equipment described in step (2) of Example 1, place the titanium tetrachloride hydrosol at room temperature and 20°C for 6 hours to obtain an aged sol; take 60mL of the aged sol into a 500mL three-necked bottle Within; take H ...

Embodiment 3

[0051] (1) Using the equipment described in step (1) in Example 1, take distilled water (H 2 O) 200mL into a three-necked bottle; take TiCl 4 100mL into a dry constant pressure separatory funnel; under the conditions of magnetic stirring and ice-water bath cooling, turn on the switch of the constant pressure separatory funnel, slowly drip the titanium tetrachloride solution into pure water, and control the dropping speed and The temperature of the ice-water bath makes the temperature of the entire dripping and mixing process controlled at about 0℃; after the titanium tetrachloride dripping is completed, continue to stir for 2 hours. At this time, the mixed system is a light yellow-green sol. Cool it to room temperature and place it. ;

[0052] (2) Using the equipment described in step (2) of Example 1, place the titanium tetrachloride hydrosol at room temperature and 20°C for 6 hours to obtain an aged sol; take 60mL of the aged sol into a 500mL three-necked bottle Within; take H ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com