Method for preparing molybdenum trioxide in nanometer structure

A molybdenum trioxide and nanostructure technology, applied in molybdenum oxide/molybdenum hydroxide, nanotechnology and other directions, can solve the problems of difficult products, complex processes, and high equipment requirements, and achieve good crystallization performance, simple process equipment, and low preparation temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing nanostructured molybdenum trioxide on a silicon substrate, the specific steps are as follows:

[0036] 1. Use a silicon substrate as the substrate, polish it with sandpaper to remove the pollutants and oxide layer on the surface, then ultrasonically clean it in acetone, absolute ethanol and deionized water for 15 minutes, and dry it;

[0037] 2. Grind the molybdenum sheet with sandpaper to remove the pollutants and oxide layer on its surface, then perform ultrasonic cleaning in acetone, absolute ethanol and deionized water for 15 minutes and dry it; place the molybdenum sheet on the heating area of the electric heating plate, Place the silicon substrate 0.5mm directly above it; turn on the heating device of the electric heating plate, and rapidly raise the temperature to 400°C; keep it warm for 12h;

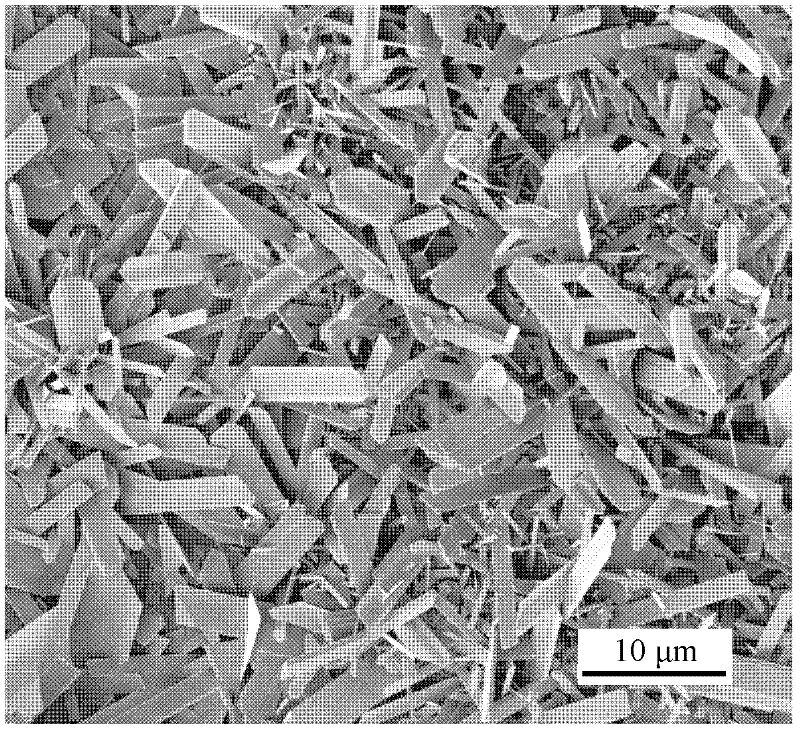

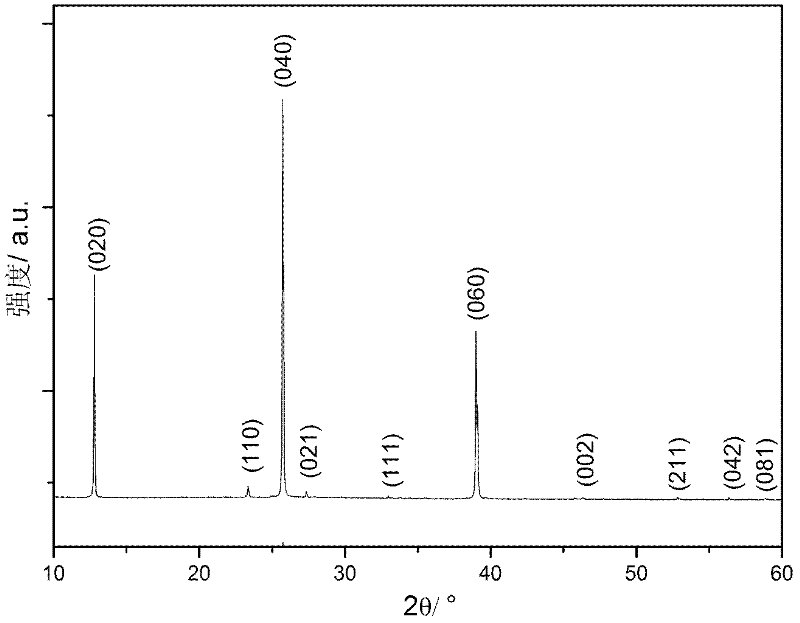

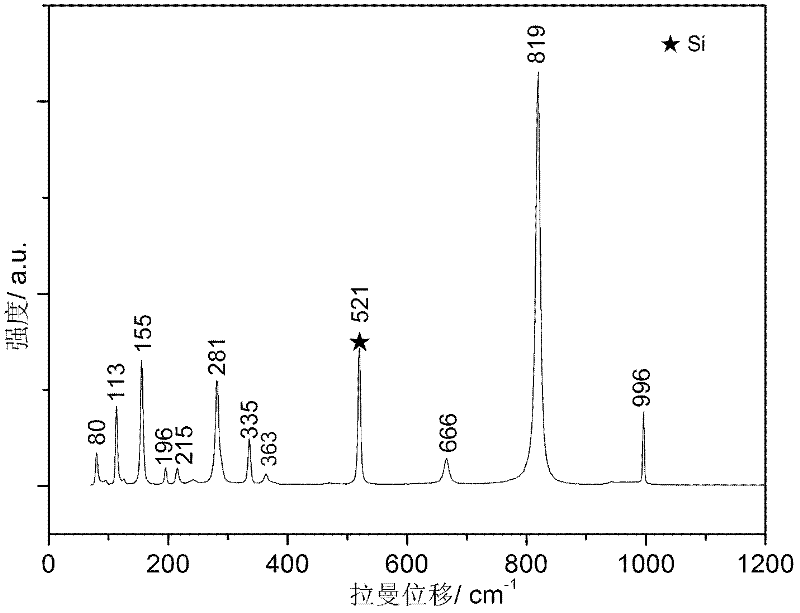

[0038] 3. Turn off the power, slowly cool down the electric heating plate and naturally cool to room temperature, then remove the silicon substrat...

Embodiment 2

[0040] The method for preparing nanostructure molybdenum trioxide on the ITO glass substrate, the concrete steps are as follows:

[0041] 1. Use an ITO glass substrate as the substrate, ultrasonically clean it in acetone, absolute ethanol and deionized water for 15 minutes and dry it;

[0042] 2. Grind the molybdenum sheet with sandpaper to remove the pollutants and oxide layer on its surface, then perform ultrasonic cleaning in acetone, absolute ethanol and deionized water for 15 minutes and dry it; place the molybdenum sheet on the heating area of the electric heating plate, Place an ITO glass substrate 0.5mm directly above it; turn on the electric heating plate heating device, rapidly raise the temperature to 450°C and keep it warm for 24h;

[0043] 3. Turn off the power, slowly cool down the electric heating plate and naturally cool to room temperature, then remove the silicon substrate. At this time, it can be observed that a layer of white transparent substance is form...

Embodiment 3

[0045] The method for preparing nanostructured molybdenum trioxide on a stainless steel substrate, the specific steps are as follows:

[0046] 1. Use a stainless steel sheet as the substrate, ultrasonically clean it in acetone, absolute ethanol and deionized water for 15 minutes and dry it;

[0047] 2. Grind the molybdenum sheet with sandpaper to remove the pollutants and oxide layer on its surface, then perform ultrasonic cleaning in acetone, absolute ethanol and deionized water for 15 minutes and dry it; place the molybdenum sheet on the heating area of the electric heating plate, Place a stainless steel substrate 0.5mm directly above it; turn on the electric heating plate heating device, rapidly raise the temperature to 500°C and keep it warm for 24h;

[0048] 3. Turn off the power, slowly cool down the electric heating plate and naturally cool down to room temperature, then remove the silicon substrate. At this time, it can be observed that a layer of white substance is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com