Electroplating wastewater treatment process

A technology for treating process and electroplating wastewater, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc. It can solve the difficulty of automatic operation of ion exchange method and the cost of wastewater treatment Increase, hidden dangers of environmental pollution and other problems, to achieve the effect of a wide range of use, reduce wastewater treatment costs, and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

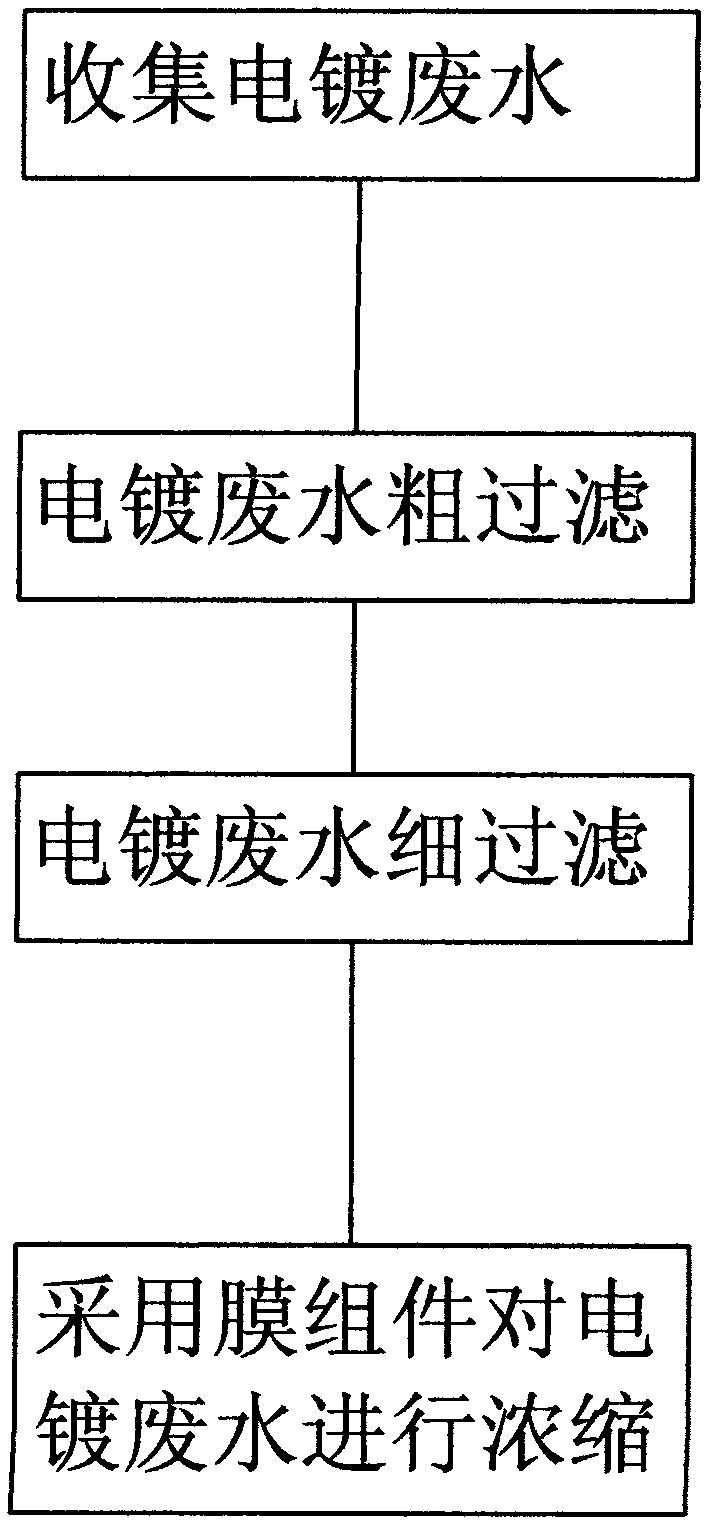

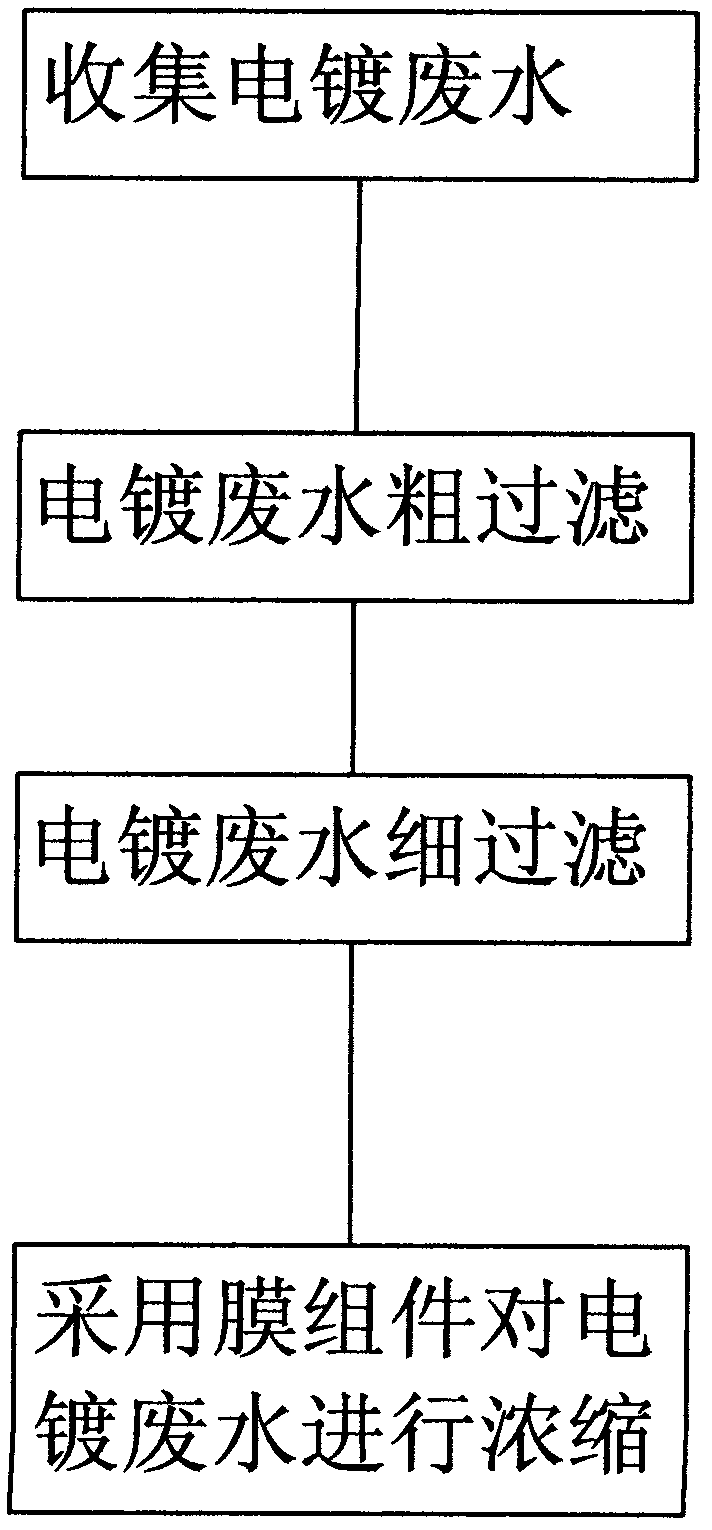

[0019] Such as figure 1 As shown, the electroplating wastewater treatment process includes the following steps: 1) Collect the electroplating waste liquid in the electroplating nickel recovery tank and the water washing tank into the waste liquid recovery tank. The way of overflow flows to the waste liquid recovery tank; 2) The electroplating waste liquid in the waste liquid recovery tank is roughly filtered through the filter to filter out impurities and particles. When the filter pressure is greater than 0.7kg / cm2, the filter element must be replaced or cleaned ; 3) Finely filter the electroplating waste liquid filtered by the filter through a security filter to filter out fine particles and suspended solids. Substances above 5 microns are allowed to pass through. The security filter must be made of SUS304 acid and alkali resistant materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com