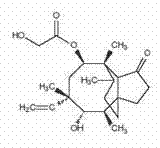

Adsorption chromatograph based method for recovering pleuromutilin from crystallization mother liquor

A technique of pleuromutilin and crystallization mother liquor, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve the problems of large impurity content, difficulty in separation and purification, waste of resources and the like, and achieves simple process, The effect of low production cost and improved industrial production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 800 grams of pleuromutilin crystallization mother liquor vacuum concentrate and dissolve in 600g of methanol, stir evenly to make upper column liquid; then use a peristaltic pump to pump the upper column liquid into a 6L non-polar The upper part of the resin column of macroporous adsorption resin HZ816, and then use 18L of methanol aqueous solution eluent with a volume concentration of 66%, elute at a flow rate of 6L / h, collect and combine the eluent, concentrate in vacuo, evaporate the water, and recover the solvent , the concentrate was added with ethyl acetate to dissolve the crystals, and the crystals were vacuum-dried to obtain the finished product. The purity of the product obtained was determined by high performance liquid chromatography. In terms of mass fraction, the purity of pleuromutilin was 97.2%, and the total recovery rate was 90.1%.

Embodiment 2

[0024] Except that the non-polar macroporous adsorption resin HZ818 is used to replace the non-polar macroporous adsorption resin HZ816, other operations are the same as in Example 1. The measurement results, in terms of mass fraction, show that the purity of pleuromutilin is 95.7%, and the total recovery rate is 85.3%.

Embodiment 3

[0026] The chromatographic column was replaced with non-polar macroporous adsorption resin HZ830, and other operations were the same as in Example 1. As a result, the purity of pleuromutilin was 92.7% and the total recovery rate was 85.8% in terms of mass fraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com