High-performance medium-temperature inorganic phase-change material and preparation method thereof

An inorganic phase change material, high-performance technology, applied in heat exchange materials, chemical instruments and methods, climate sustainability, etc., can solve the problems of unstable phase separation, difficult long-term use, etc., and achieve simple and easy preparation methods Good encapsulation and recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A high-performance medium-temperature inorganic phase change material, the raw materials and mass percentages are:

[0021] Magnesium nitrate hexahydrate (Mg(NO 3 ) 2 ·6H 2 O) 86%

[0022] Lithium nitrate (LiNO) 3 ) 14%.

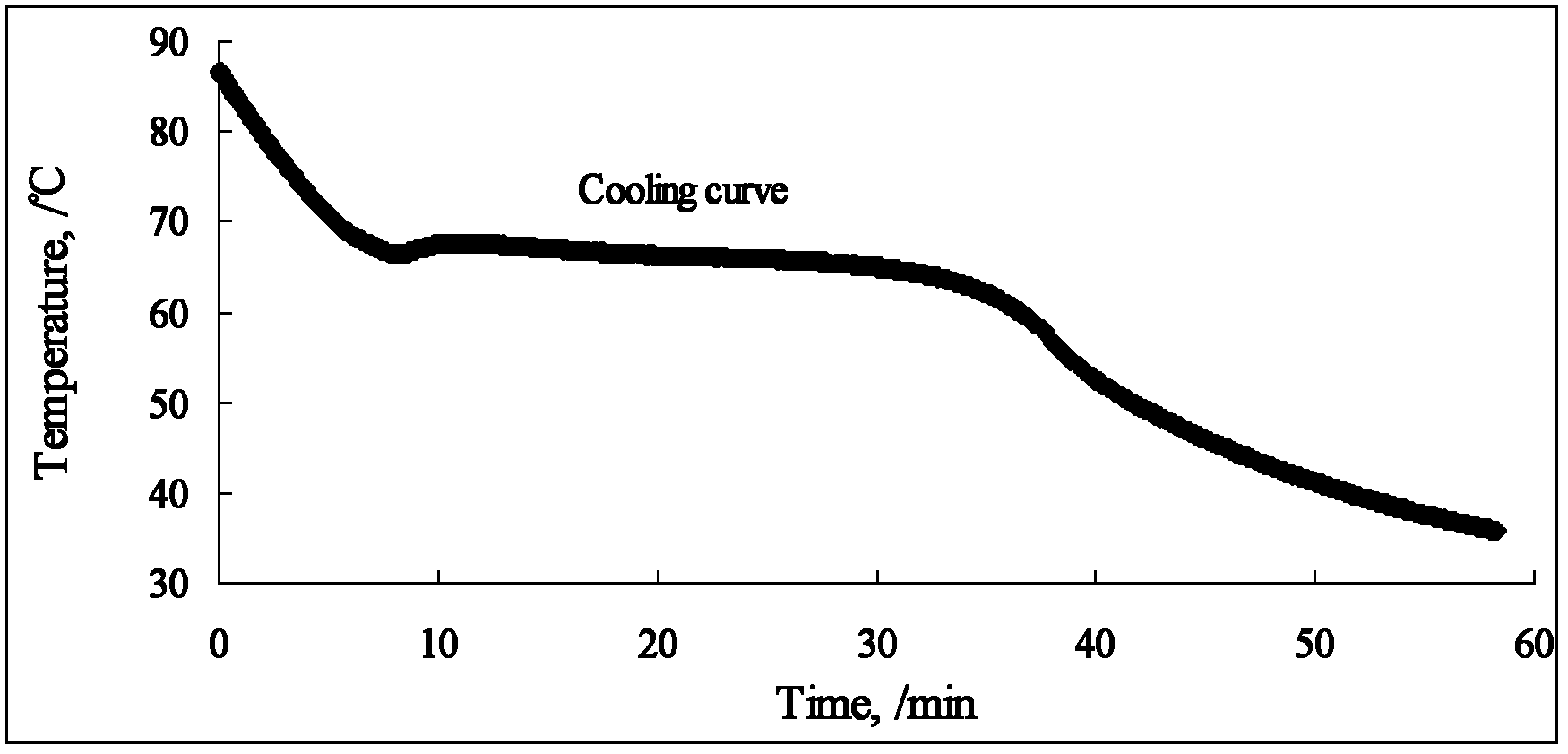

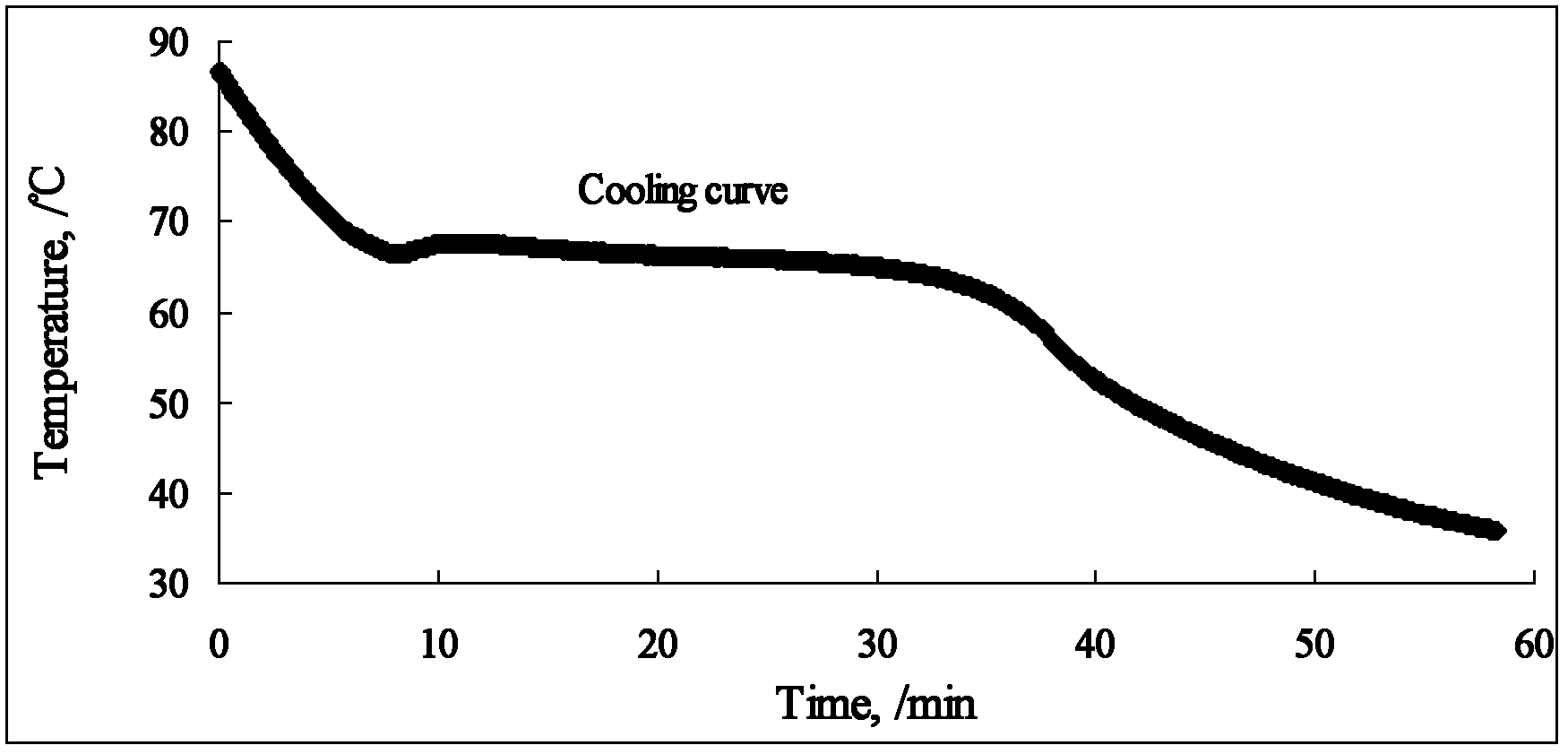

[0023] The preparation method is as follows: according to the above mass ratio, the crystal of magnesium nitrate hexahydrate and lithium nitrate are uniformly mixed to obtain a heat storage system, and the above heat storage system is placed in a glass test tube with a diameter of 30 mm, melted in a 90 ℃ water bath, and the sample is completely melted. Then keep the temperature for more than 10min to make the sample mix more evenly, and finally pour the mixture into a container for packaging.

[0024] The following matters should be paid attention to in the production process:

[0025] 1. The packaging container can be made of plastic or metal, and the shape can be spherical, rectangular, cubic or cylindrical, but no matter which packaging metho...

Embodiment 2

[0029] A high-performance medium-temperature inorganic phase change material, the raw materials and mass percentages are:

[0030] Magnesium nitrate hexahydrate (Mg(NO 3 ) 2 ·6H 2 O) 90%;

[0031] Lithium nitrate (LiNO) 3 ) 10%.

[0032] The preparation method is as follows: uniformly mixing magnesium nitrate hexahydrate crystals and lithium nitrate according to the above mass ratio to obtain a heat storage system, placing the above heat storage system in a glass test tube with a diameter of 30 mm, and heating it in a 90°C water bath until the sample is melted. , the sample is completely melted and then kept for more than 10 minutes to make the sample mix more evenly, and finally the mixture is poured into a container for packaging.

[0033] The following matters should be paid attention to in the production process:

[0034] 1. The packaging container can be made of plastic or metal, and the shape can be spherical, rectangular, cubic or cylindrical, but no matter which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com