Process for determining residual monomers in adhesive

A technology for residual monomers and determination methods, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of unpleasant irritating odor of products, cumbersome operation, and error of analysis results, so as to avoid harm to health and improve the technical field , strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Instrument preparation:

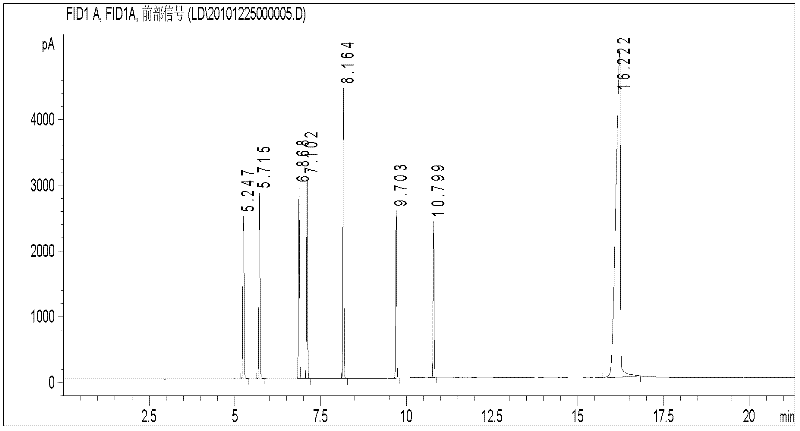

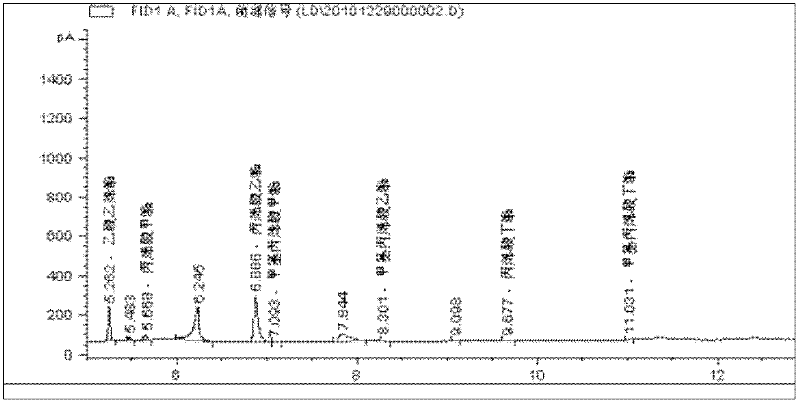

[0036] Agilent 7890 headspace gas chromatograph was used, and the headspace conditions were as follows: equilibrate at 120°C for 30 min; ℃; carrier gas He gas (purity ≥ 99.999%); constant flow rate 3.0mL / min; split ratio 10:1; heating program initial column temperature 60 ℃, keep for 2min, raise the temperature to 200℃ at 15℃ / min, keep for 10min ; Hydrogen flame ionization detector at a temperature of 220°C.

[0037] 2. Preparation of standard working curve:

[0038] 1) Preparation of standard stock solution: Accurately weigh 100 mg of standard samples (purity ≥ 99%) of 7 kinds of residual monomer compounds, dilute with N,N-dimethylformamide and dilute to 100 mL volumetric flask to make 1.0 mg / mL of mixed standard stock solution;

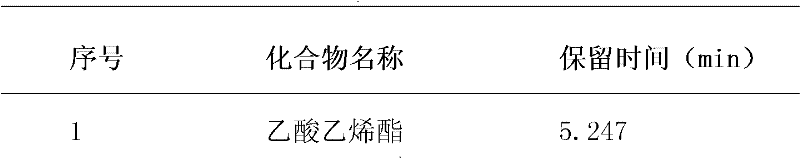

[0039] 2) Prepare mixed standard working solution: Weigh the above stock solution and dilute it step by step with N,N-dimethylformamide to obtain a series of 0.2mg / mL, 0.04mg / mL, 0.008mg / mL, 0.0016mg / mL stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com