Flow field pressure transducer of immersion lithography machine based on PVDF (polyvinylidene fluoride)

A technology of pressure sensor and lithography machine, which is applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, and microlithography exposure equipment, etc. The production process of the sensor is complicated, and it is difficult to meet the installation requirements, etc., to achieve the effect of ensuring no distortion, small space occupation, and convenient and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation process of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

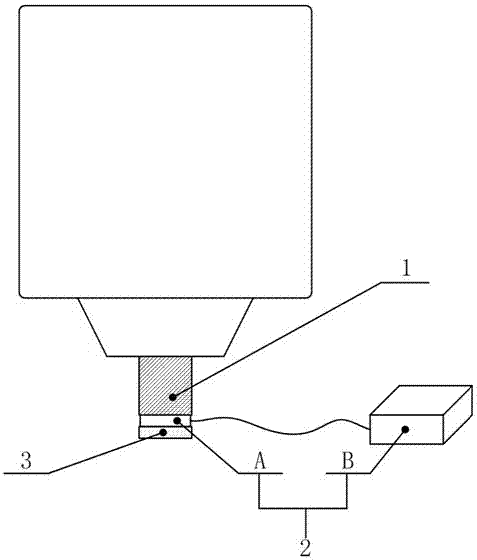

[0039] Such as figure 1 As shown, the present invention is a flow field pressure sensor 2 attached to the lower surface of the projection lens model 1 and immersed in the liquid film 3; the flow field pressure sensor 2 includes a PVDF pressure sensing element A containing a shielding film and a signal Processing device B; the present invention can be applied in photolithographic equipment such as step-and-repeat or step-and-scan, when in use, the projection lens model 1 does not move, and the PVDF pressure sensing element A containing the shielding film accepts the pressure fluctuation of the liquid film 3 The excitation generates a pressure signal, which is output to the signal processing device B, and finally output to a monitoring device such as an oscilloscope.

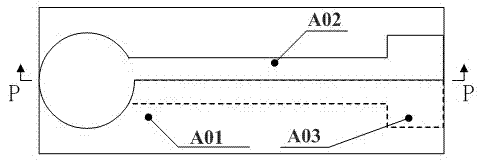

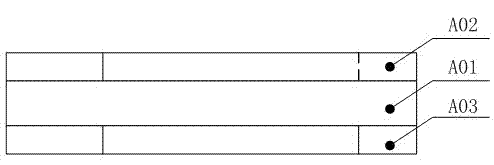

[0040] Such as figure 2 , image 3 , Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com