Gas diffusion electrode employing nano MnO2 catalyst

A gas diffusion electrode and catalyst technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of affecting electrode performance, poor conductivity, easy agglomeration, etc., to overcome poor conductivity, good conductivity, particle size small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

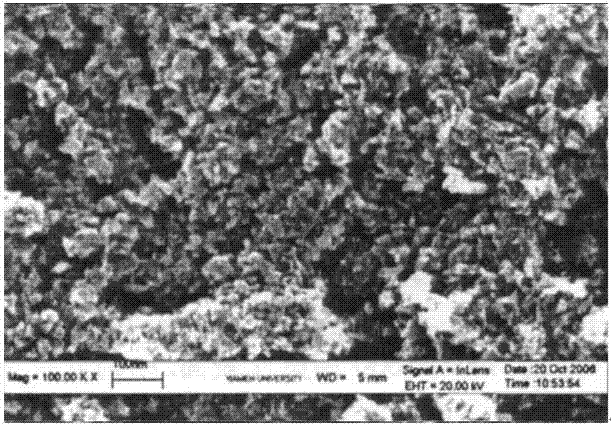

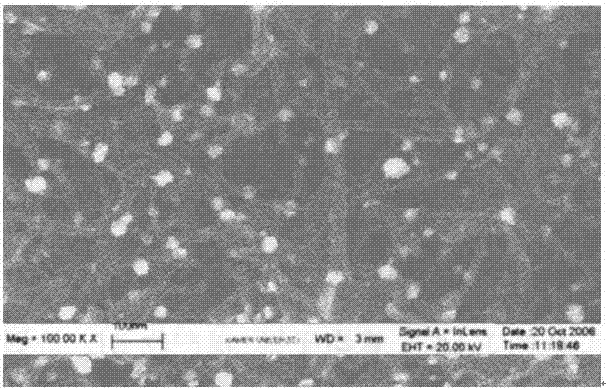

[0032] Activated carbon-supported nano-MnO was prepared by the following steps 2 catalyst:

[0033] Step 1: Perform high-temperature pretreatment on activated carbon and air oxidation at 180°C for 5 hours;

[0034] Step 2, disperse the activated carbon treated in step 1 with a small amount of absolute ethanol, drop in the saturated solution of MnSO4 drop by drop, then immerse in vacuum for 3h, then add KOH solution to alkalinize, and generate jelly;

[0035] Step 3: wash the jelly obtained in step 2 with distilled water, dry it, and oxidize it at 300°C for 5 hours to obtain activated carbon-supported nano-MnO 2 catalyst.

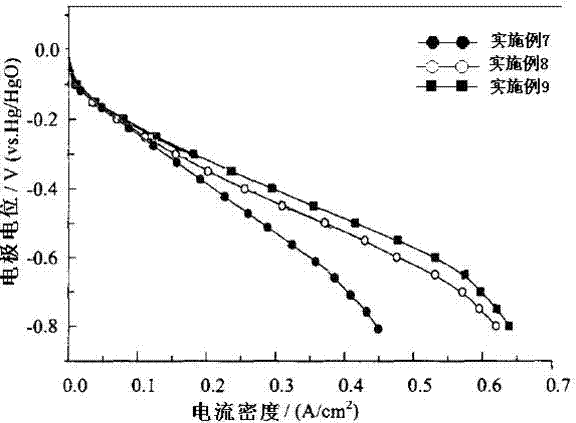

Embodiment 2

[0037] This example is the same as Example 1, except that in step 1, air oxidation is performed at 200° C. for 3.5 hours; in step 2, vacuum immersion is performed for 2 hours; in step 3, oxidation is performed at 350° C. for 4 hours.

Embodiment 3

[0039] This example is the same as Example 1, except that in step 1, air oxidation is performed at 220° C. for 2 hours; in step 2, vacuum immersion is performed for 1 hour; in step 3, oxidation is performed at 380° C. for 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com