Hexaaluminate-doped oxide catalyst and preparing method and application thereof

A technology of hexaaluminate and catalyst, applied in the field of synthesis gas preparation, can solve problems such as low catalytic efficiency, and achieve the effects of simplifying preparation process, reducing cost, and improving catalytic performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

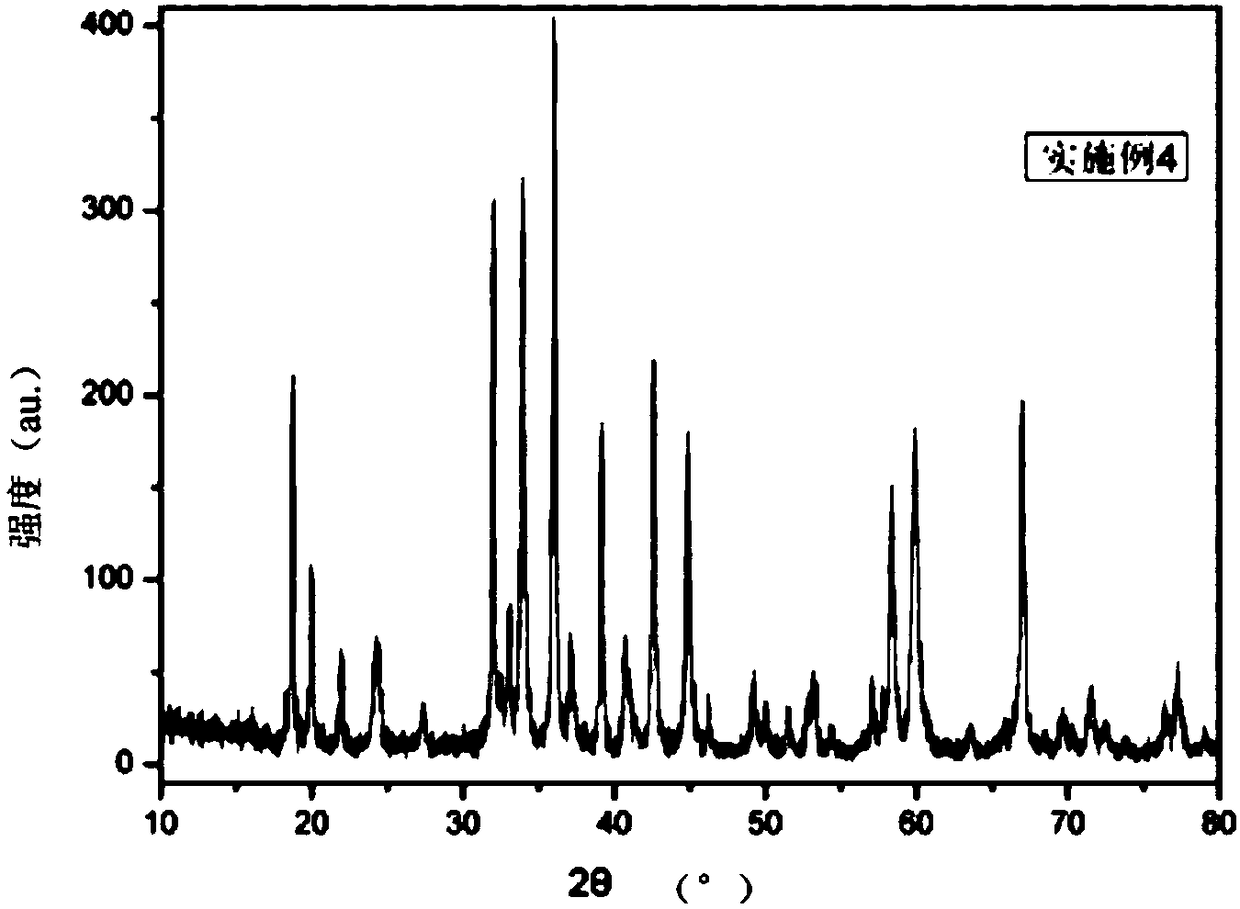

Image

Examples

preparation example Construction

[0030] In another typical embodiment of the present application, a method for preparing a catalyst is provided, the general formula of the catalyst is Re 0.8 Zr x m A Ni 1-A Al 11 o 19-δ , wherein, Re is La or Sr, M is Co, Fe, Mn or Cu, 0≤x≤0.2, 0≤A≤1, and the preparation method includes: respectively preparing Re elements, Salt solution of Zr element, M element, Ni element and Al element; mix each salt solution with isopropanol solution of polyethylene glycol to form a mixed system; water bath treat the clarified mixed system to gel , to obtain a gel; and sequentially drying and calcining the gel to obtain a catalyst.

[0031]The above-mentioned isopropanol solution of polyethylene glycol is used as a dispersant, the salt solution of each element is mixed with the isopropanol solution of polyethylene glycol, and then the gel can be obtained by conventional water bath heating treatment; The catalyst of the present application can be obtained by drying and calcining under...

Embodiment 1

[0044] Hexaaluminate Catalyst La with Zr Partial Substitution of La 0.8 Zr x co 0.5 Ni 0.5 al 11 o 19-δ , Prepared by high-temperature roasting nitrate method. Put La(NO 3 ) 3 ·6H 2 O, Zr(NO 3 ) 4 ·5H 2 O, Co(NO 3 ) 2 ·6H 2 O, Ni(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O was dissolved in distilled water at a molar ratio of 0.8:0:0.5:0.5:11 to prepare a mixed solution. Then slowly drop the mixed solution into 50mL of hot isopropanol solution containing 3g of polyethylene glycol 20000 to form a mixed system, put the clarified mixed system into a water bath at 80°C and steam until it becomes a gel to obtain a gel, and then Dry the gel in an oven at 150°C and grind it into powder, then bake the powder in a low-temperature muffle furnace at 400°C for 2 hours, then put it in a high-temperature muffle furnace and bake it at 1250°C for 5 hours, lower it to room temperature, and press into tablets , Granulated, the particle size is 20~60 mesh particles as the catalys...

Embodiment 2

[0046] The present embodiment is different from specific embodiment 1 in that: La(NO 3 ) 3 ·6H 2 O, Zr(NO 3 ) 4 ·5H 2 O, Co(NO 3 ) 2 ·6H 2 O, Ni(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O in a molar ratio of 0.8:0.02:0.5:0.5:11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com