Gel-type polymer electrolyte and preparation method thereof

A technology of electrolytes and polymers, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as large electrolyte adsorption, reduced electrolyte stability, and complicated preparation processes, and achieves easy film formation and wide electrochemical The effect of stable window and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

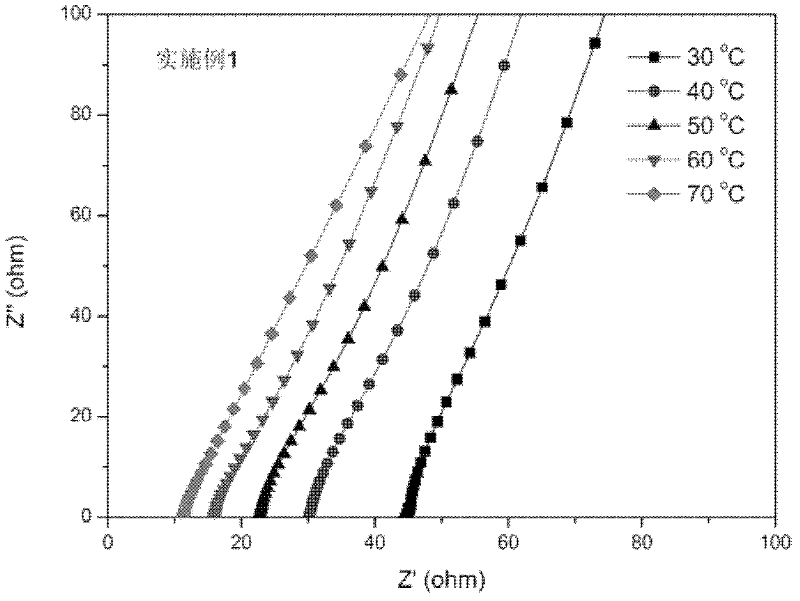

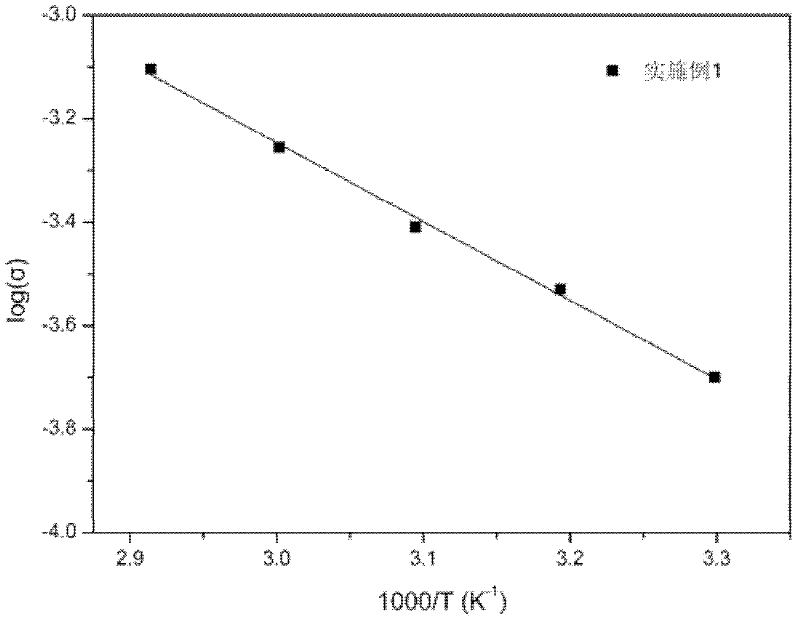

[0034] A preparation method of a gel-type polymer electrolyte, the raw materials of which are composed of the following components: amino-terminated nitrile rubber, epoxidized cyclohexyl polyhedral polysilsesquioxane, lithium perchlorate, 1-butyl-3 - Methylimidazole trifluoromethanesulfonate, wherein the amino-terminated nitrile rubber has an acrylonitrile content of 18 wt%, a Brookfield viscosity of 200,000 cP, an amino equivalent weight of 900, and an amine value of 62.

[0035] The preparation method of gel-type polymer electrolyte comprises the following process steps: according to the formula of table 1, amino-terminated nitrile rubber, lithium perchlorate, epoxidized cyclohexyl polyhedral polysilsesquioxane and 1-butyl-3 - Methylimidazole trifluoromethanesulfonate was magnetically stirred in 30 parts of tetrahydrofuran for 30 minutes to obtain a uniform and transparent mixed solution, which was cast into a polytetrafluoroethylene mold. After the tetrahydrofuran was comple...

Embodiment 5

[0047] A preparation method of a gel-type polymer electrolyte, the raw materials of which are composed of the following components: amino-terminated nitrile rubber, epoxidized cyclohexyl polyhedral polysilsesquioxane, lithium trifluoromethanesulfonate, 1-butyl - 3-methylimidazolium trifluoromethanesulfonate, wherein the amino-terminated nitrile rubber has an acrylonitrile content of 10 wt%, a Brookfield viscosity of 180,000 cP, an amino equivalent weight of 1200, and an amine value of 47.

[0048] The preparation method of the gel-type polymer electrolyte comprises the following process steps: 1 part of amino-terminated nitrile rubber, 0.2 part of lithium trifluoromethanesulfonate, 0.2 part of epoxidized cyclohexyl polyhedral polysilsesquioxane, 0.2 part 1-butyl-3-methylimidazole trifluoromethanesulfonate was magnetically stirred in 30 parts of tetrahydrofuran for 30 minutes to obtain a uniform and transparent mixed solution, which was cast into a polytetrafluoroethylene mold. ...

Embodiment 6

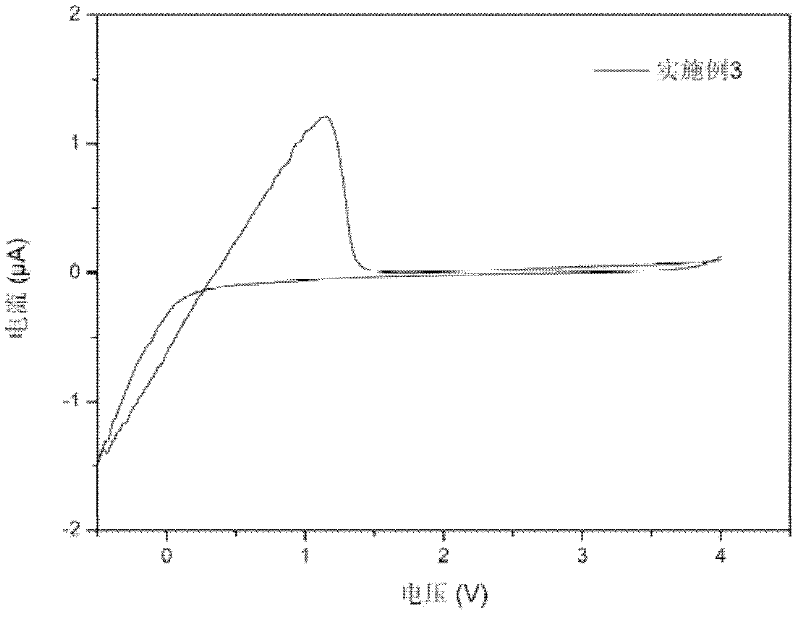

[0050] A preparation method of a gel-type polymer electrolyte, the raw materials of which are composed of the following components: amino-terminated nitrile rubber, epoxidized cyclohexyl polyhedral polysilsesquioxane, lithium bistrifluoromethanesulfonimide, 1 - Butyl-3-methylimidazolium trifluoromethanesulfonate, wherein the amino-terminated nitrile rubber has an acrylonitrile content of 26 wt%, a Brookfield viscosity of 500,000 cP, an amino equivalent weight of 700, and an amine value of 80.

[0051] The preparation method of the gel-type polymer electrolyte comprises the following process steps: 1 part of amino-terminated nitrile rubber, 0.6 part of lithium bistrifluoromethanesulfonimide, 0.05 part of glycidyl ether polyhedral polysilsesquioxane, 1 part One part of 1-butyl-3-methylimidazole trifluoromethanesulfonate was magnetically stirred in 30 parts of tetrahydrofuran for 30 minutes to obtain a uniform and transparent mixed solution, which was cast into a polytetrafluoroet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brookfield viscosity | aaaaa | aaaaa |

| Brookfield viscosity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com