Low-bulk-density composition for reducing discharge of regenerated flue gases CO and NOx during FCC (Fluid Catalytic Cracking)

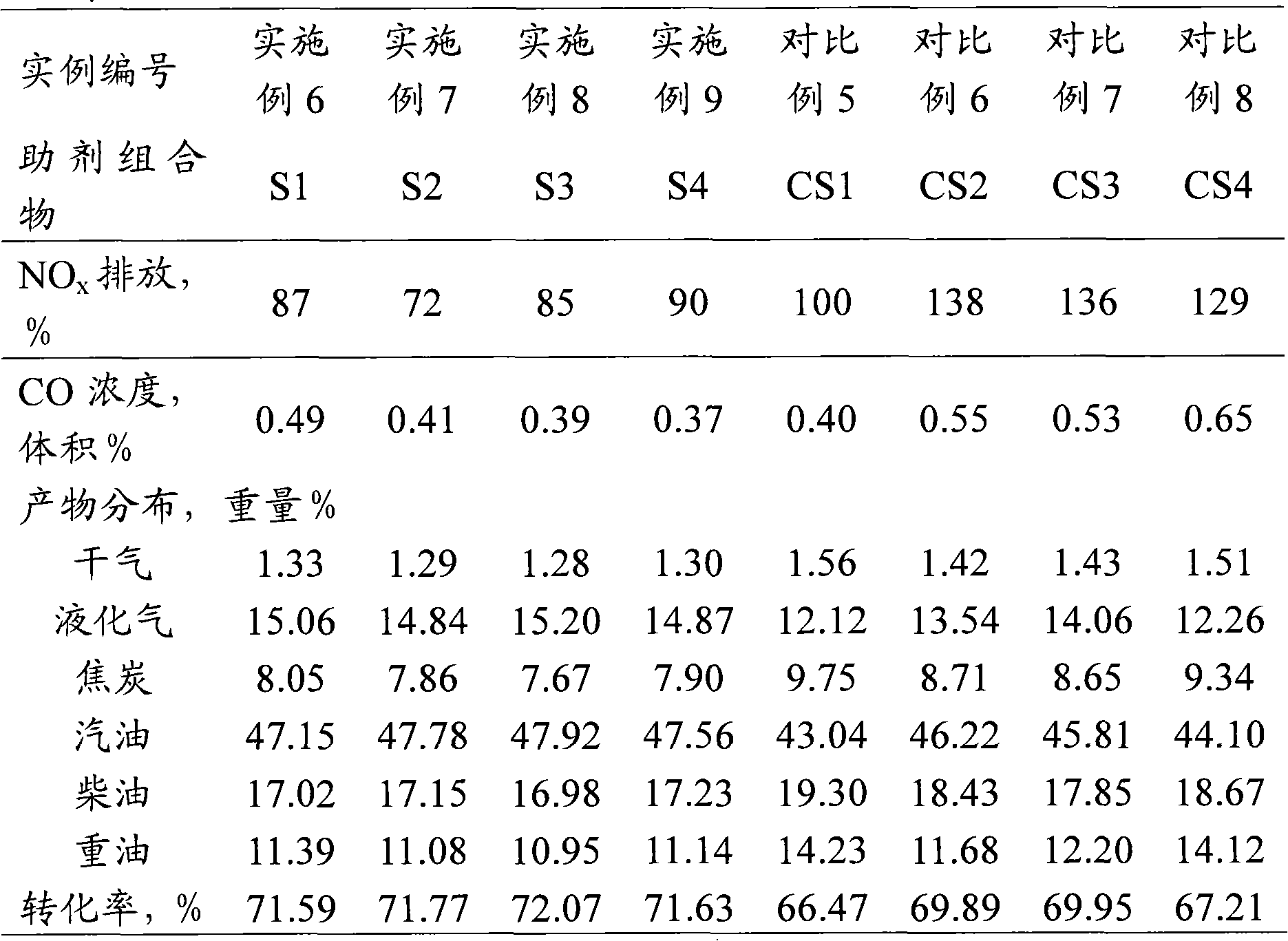

A technology for regenerating flue gas and composition, applied in the field of low-to-heap ratio non-precious metal composition, can solve the problems of low emission performance, poor distribution of catalytic cracking products, high yield of coke and dry gas, and achieves reduction of coke and dry gas. Yield, improved product distribution, reduced CO and NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

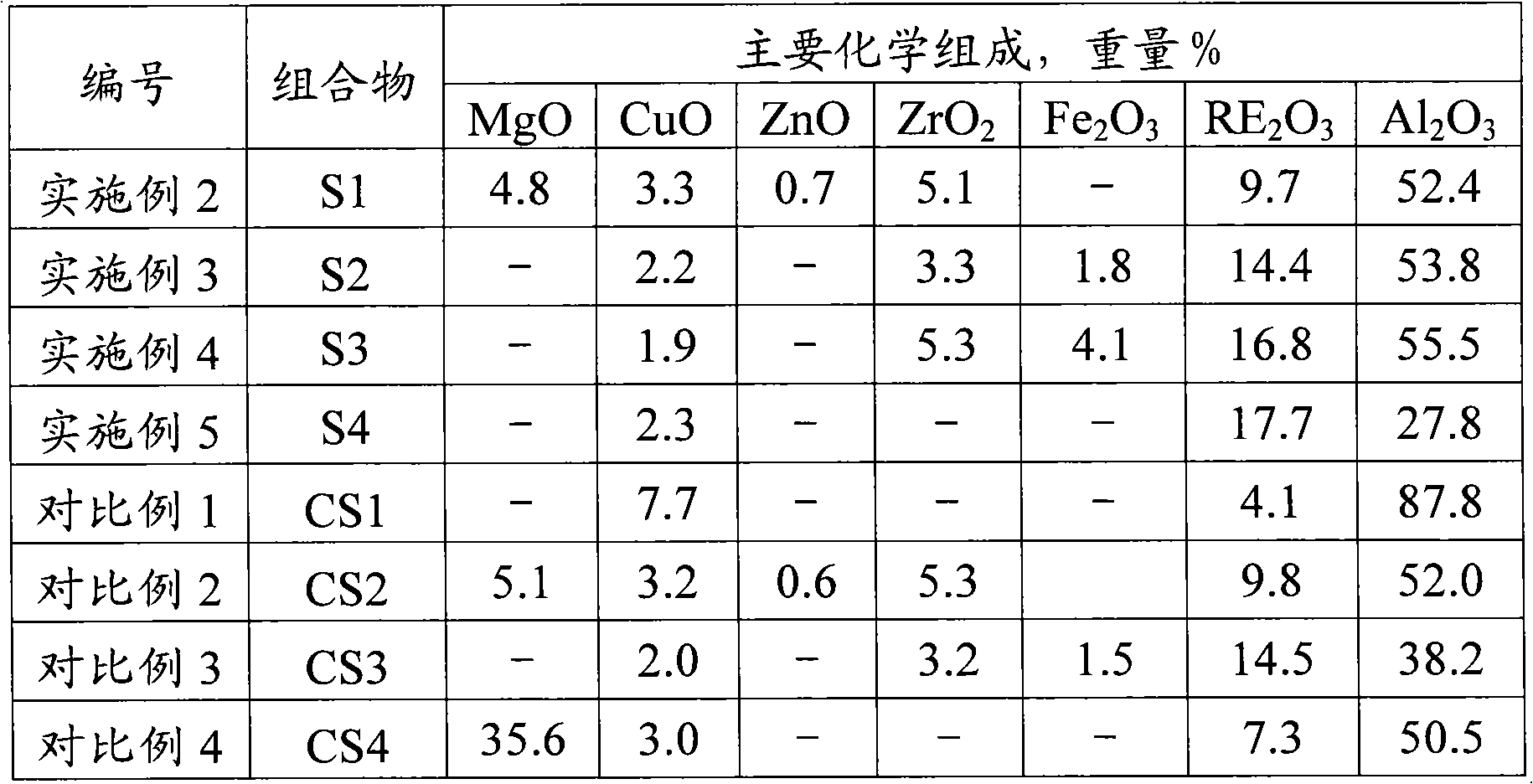

[0025] The method provided by the present invention reduces CO and NO in catalytic cracking regenerated flue gas x In the preparation method of the discharged composition, the compound of the non-noble metal element may be its oxide, chloride, sulfate, nitrate, preferably a soluble salt of the non-noble metal element. The non-noble metal elements are selected from one or more of the non-noble metal elements of Groups IIA, IB, IIB, IVB, VIB and VIII, preferably Mg, Ca, Cu, Zn, Cd, Ti, Zr, Cr, Mo , one or more of W, Fe and Co, more preferably one or more of Mg, Cu, Zn, Zr and Fe. The non-noble metal element can be loaded on the inorganic oxide carrier, or on the zeolite component, preferably the metal selected from the IB and IIB groups is loaded on the zeolite, and the metals from other groups are loaded on the carrier. In order to load the metals of the IB and IIB groups on the zeolite, the zeolite can be impregnated or exchanged with the zeolite with the compound solution of...

Embodiment 1

[0033] This example illustrates the exchange treatment and preparation of the metal component loaded Y zeolite used in the compositions of the present invention.

[0034] Use conventional methods to exchange Y-type zeolite samples to reduce zeolite Na 2 O content. Weigh 2 kg each of DASY (0.0) and REHY (7.0) zeolites on a dry basis, add them to 20 L of deionized water at a temperature of 85-90 ° C, stir, add 800 g of ammonium chloride each, and then use a mass concentration of 19.8% dilute hydrochloric acid to adjust the pH value between 3-3.5, exchange treatment for 1 hour, filter, dry, and roast at 550°C for 1 hour to obtain Na 2 Low-sodium DASY (0.0) zeolite with an O content of 0.31% by weight and Na 2 Low-sodium REHY (7.0) zeolite with an O content of 0.87% by weight is used for future use.

[0035] Weigh 307.3 grams of copper nitrate and 37.7 grams of zinc chloride to prepare a 1000 mL solution, add 1 kg of the low-sodium DASY (0.0) zeolite obtained above to the prepa...

Embodiment 2

[0038] This embodiment illustrates the reduction of FCC regeneration flue gas CO and NO according to the present invention x Preparation of Emission Composition S1.

[0039] Feed intake dry basis gross weight 2.5 kilograms, wherein (weight percentage) CZ-USY zeolite (dry basis) 35%, macroporous pseudo-boehmite (with Al 2 o 3 Weight) 40%, aluminum sol (as Al 2 o 3 by weight) 5%, magnesia (by weight of MgO) 5%, zirconia (by weight of ZrO 2 Weight) 5%, rare earth (in RE 2 o 3 by weight) 10%.

[0040] Weigh 875 grams of the CZ-USY sample prepared in Example 1, mix it with 1800 milliliters of water for beating, and grind it evenly (ground to an average particle size ≤ 3.5 microns, and the average particle size in this example is 3.2 microns).

[0041] Weigh 1370 grams of macroporous pseudo-boehmite, mix it with 4500 milliliters of deionized water for beating, add 926 milliliters of mixed rare earth solution, then add 240 milliliters of dilute hydrochloric acid with a mass co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com