Method for preparing propylene by using etherified C4 and ethylene

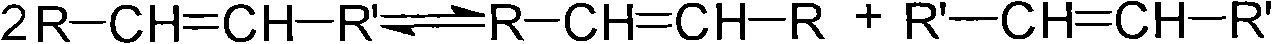

A technology of C4 and ethylene after ether, which is applied in the direction of double decomposition reaction to hydrocarbon, organic chemistry, etc., can solve the problems of low selectivity of target products, low utilization rate of C4 raw materials, etc., and achieve the effect of improving utilization rate and benefiting life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this reaction, the flow rate of ethylene is 34733.3Kg / h, the ratio of ethylene and butene is 2:1 in terms of molar ratio, and the material balance is shown in Table 2.

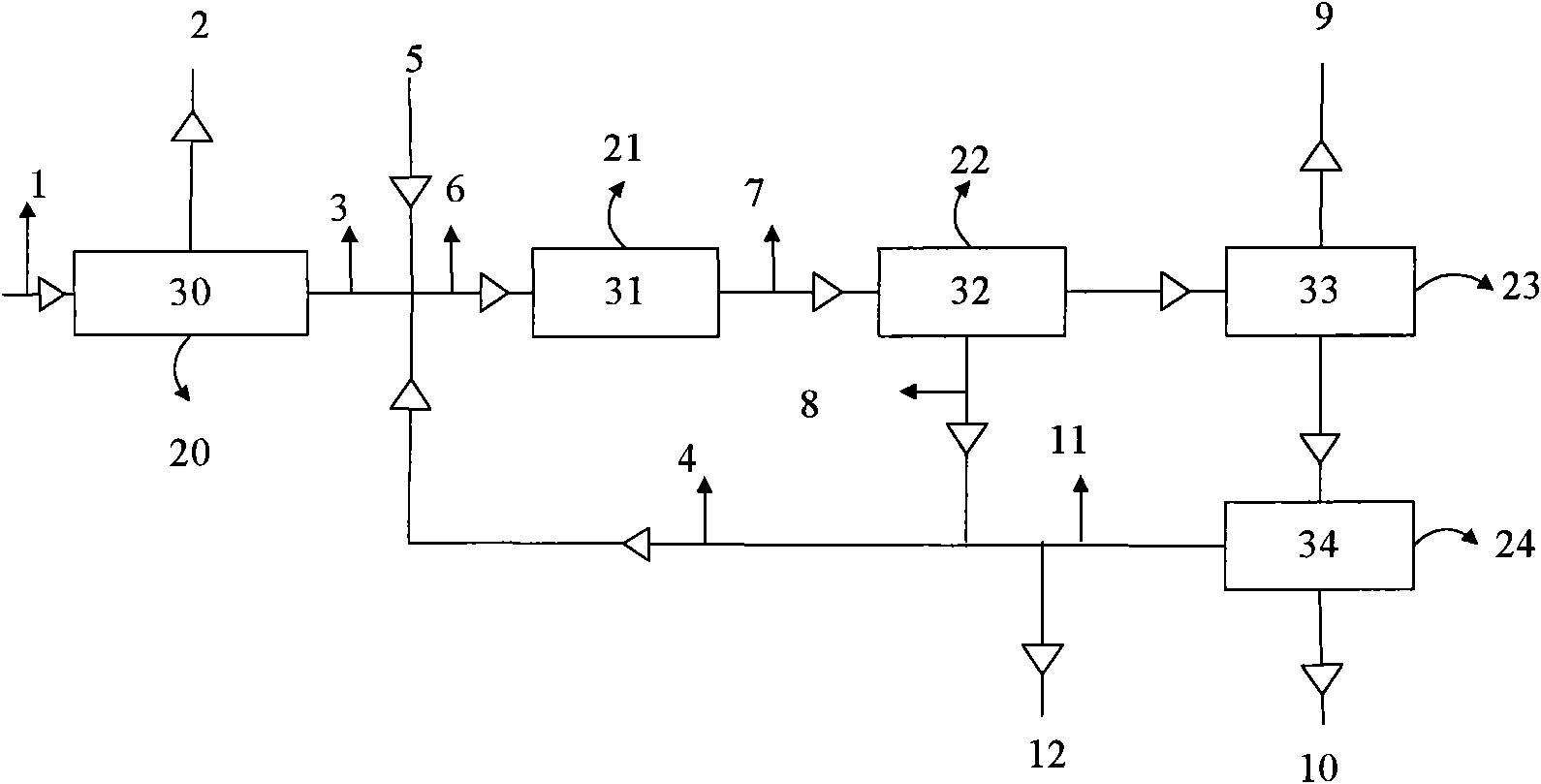

[0033] Step 1: First, the ether C4 stream and ethylene are respectively passed through respective adsorption towers (adsorption tower 30 and adsorption tower 31) to remove impurities in the raw material, and the main products 5 and 6 removed in the two adsorption towers mainly include Water, alcohol and ether, the adsorbent is 13X molecular sieve, the content of water after the raw material passes through the adsorbent is 3ppmw, the content of carbon dioxide is 0.5ppmw, the content of total sulfur is 0.2ppmw, the content of total nitrogen is 0.3ppmw, and the content of total oxygenated compounds The content is 0.6ppmw, the content of total halides is 0.1ppmw, and the content of heavy metal components is 0.2ppb.

[0034] Step 2: Mix 55600kg / h post-ether C4 material 3 and 34733.3Kg / h ethylene material 4 ...

Embodiment 2

[0041] In this reaction, the flow rate of ethylene is 17366.6Kg / h, the ratio of ethylene and butene is 1:1 in terms of molar ratio, and the material balance is shown in Table 3.

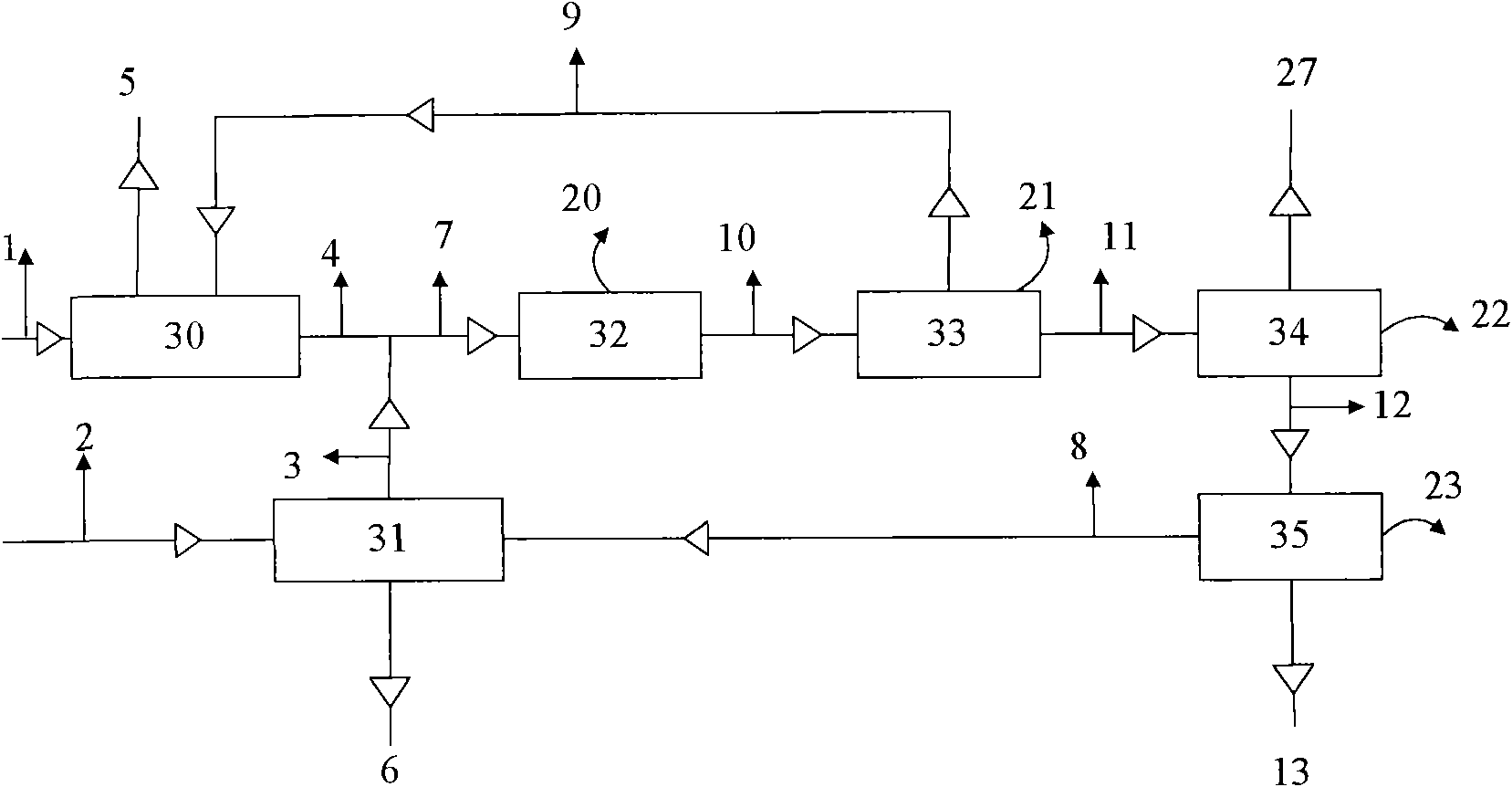

[0042] According to each step in embodiment 1, change total ethylene material 3 to be 17366.6Kg / h, change the weight ratio of disproportionation catalyst and isomerization catalyst to be 1: 5, change operating conditions to be: reaction temperature 250 ℃, reaction pressure 0.1MPa , the mass space velocity of C4 1h -1 ; Change the operating conditions of the debutanizer to: 50 trays, tower top: 1MPa, 40°C; the operating conditions of the deethylene tower: 140 trays, tower top: 0.5MPa, -65°C; The operating conditions are: 240 trays, tower top: 1.7MPa, 40°C;

[0043] The composition analysis of material in the reaction process of table 3

[0044]

Embodiment 3

[0046] In this reaction, the flow rate of ethylene is 56149.8Kg / h, the ratio of ethylene and butene is 3:1 in terms of molar ratio, and the material balance is shown in Table 4.

[0047] According to each step in embodiment 1, only change total ethylene material 3 to be 56149.8Kg / h and the weight ratio of disproportionation catalyst and isomerization catalyst to be 1: 5; Change operation condition to be: 350 ℃ of reaction temperatures, reaction pressure 1MPa, The mass space velocity of C4 is 10h -1 ; Change the operating conditions of the debutanizer to: 60 trays, tower top: 1.5MPa, 50°C; the operating conditions of the deethylene tower: 150 trays, tower top: 0.7MPa, -60°C; The operating conditions of the tower are: 250 trays, tower top: 1.9MPa, 50°C;

[0048] The composition analysis of material in the reaction process of table 4

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com