Terpolymer rubber with medium/high side group content and preparation method and applications thereof

A vinyl aromatic hydrocarbon terpolymer and terpolymer technology, which is applied in the field of new terpolymer rubber, can solve the problems of environmental protection and operating environment, such as insufficient safety, strong, irritating odor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

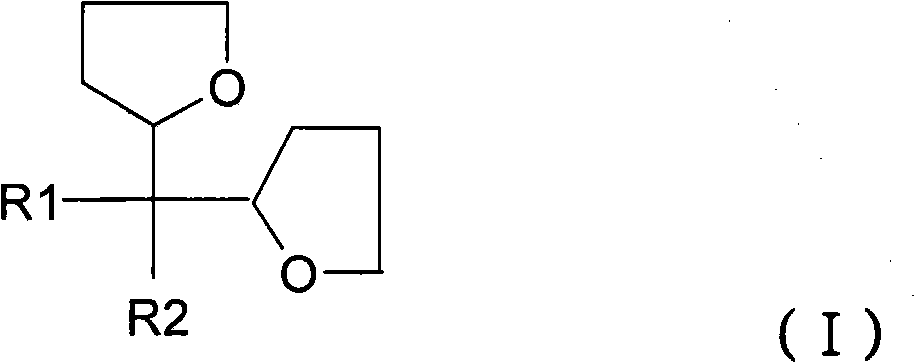

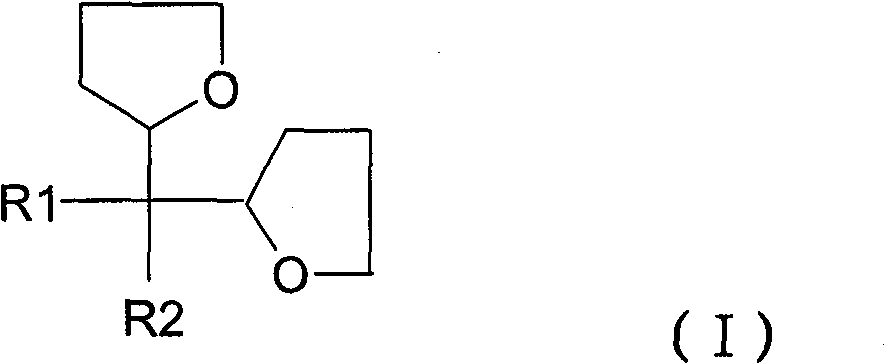

Image

Examples

Embodiment 1

[0055] Under the protection of high-purity nitrogen, the mixed solvent (mixture of cyclohexane and n-hexane: 82 / 18, mass ratio), styrene (ST), isoprene (IP), butadiene ( BD) and ditetrahydrofurfurylpropane (DTHFP) were added to a 5-liter stainless steel polymerization reactor with stirring. The reaction kettle was heated to 40°C by heating the jacket with hot water, the polymerization pressure was controlled between 0.1 MPa and 0.3 MPa, and n-butyl lithium was added to initiate the reaction. After 60 minutes of polymerization, tin tetrachloride was added for coupling for 30 minutes. Then, isopropanol in an amount of 1.2 times (molar ratio) of n-butyl lithium is added to terminate the reaction, and after condensation with water vapor, a random ternary copolymer rubber product is obtained. The product microstructure and various properties are shown in Table 1.

Embodiment 2-4

[0057] It was carried out according to the procedure described in Example 1, with the difference that the polymerization initiation temperature was 50°C, 60°C, and 70°C, respectively. The product microstructure and various properties are shown in Table 1.

[0058] Table 1 Product microstructure and various properties

[0059] Item

Embodiment 5-11

[0061] According to the procedure described in Example 2, the difference is that the amount of structure adjustment added to the polymerization system is adjusted so that the ratio of it to the organic lithium becomes 0.1, 0.2, 0.4, 0.6, 0.7, 1.0, 2.0, and the product The microstructure and various properties are shown in Table 2 below.

[0062] Table 2 Product microstructure and various properties

[0063] Item

PUM

| Property | Measurement | Unit |

|---|---|---|

| coupling rate | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com