Method for preparation of acetic anhydride and acetic acid by means of carbonyl synthesis of methyl acetate and methanol azeotrope and method for separation

A methyl acetate and oxo synthesis technology, which is applied in the separation/purification of carboxylic acid compounds, chemical instruments and methods, and preparation of carboxylic anhydrides, can solve the problems of difficult separation and large steam consumption, and achieve short process flow and protection Environmental and emission reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

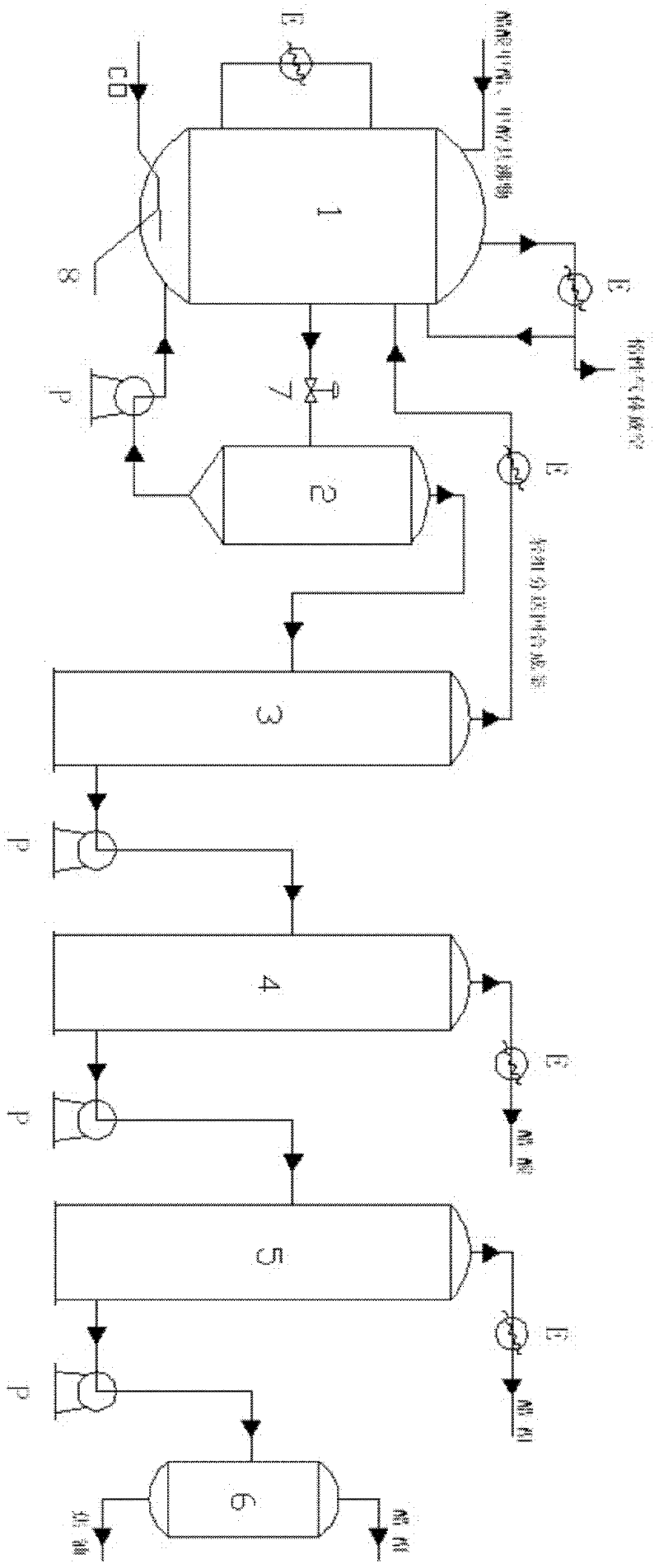

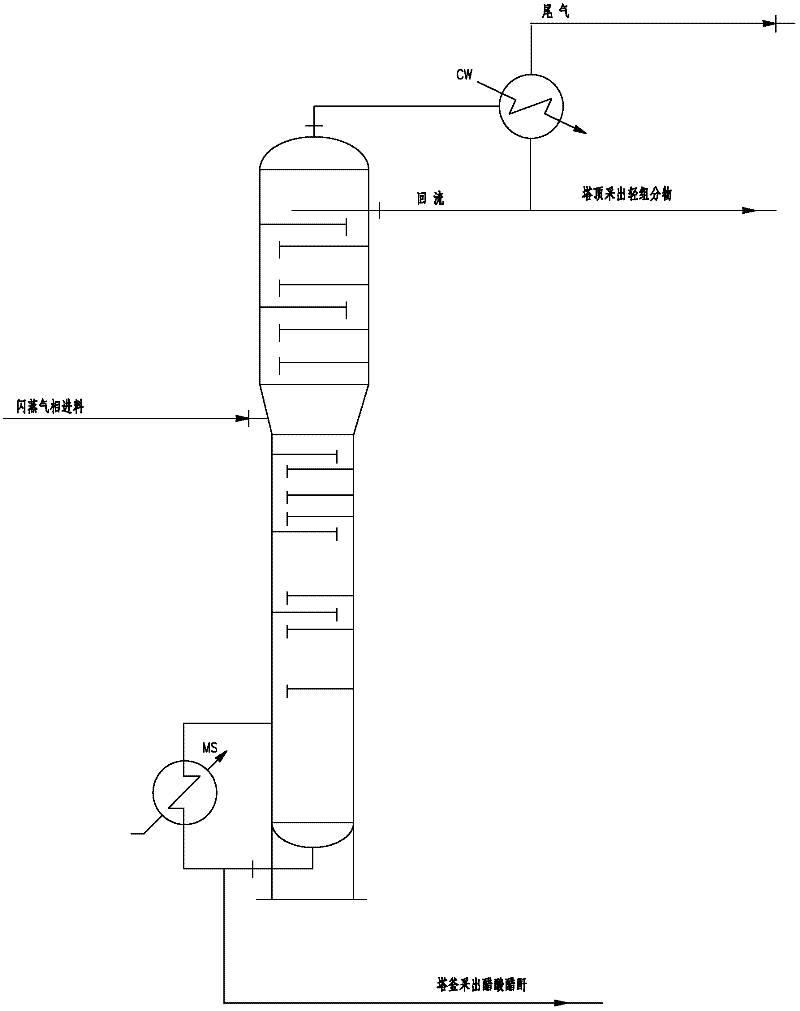

[0023] In conjunction with the accompanying drawings, the specific implementation process is described as follows:

[0024] (1) Preparation of rhodium catalyst

[0025] RhI 3 or RhCl 3 Put it into the preparation kettle, add acetic acid (HAc), control the Rh concentration at 1000-2000ppm, and then introduce CO, control the pressure in the kettle at 0.35MPa, stir and heat up to 120°C, keep warm, keep the pressure, and pump it in after 8 hours Inside the synthesis kettle.

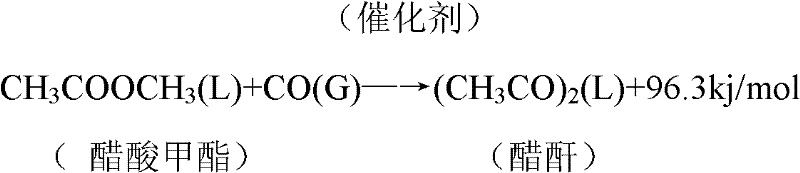

[0026] (2) Carbonylation of acetic anhydride and acetic acid

[0027] 1. The azeotrope is added from the top of the oxo synthesis kettle 1, stirring is started, the rhodium catalyst solution is added, methyl iodide and lithium acetate are added simultaneously, the temperature is raised, the pressure is increased, and CO gas is fed through the gas distributor 8 from the bottom of the kettle simultaneously, The feeding amount is 5-30% (v / w) of the reaction liquid amount. When the reaction starts, open the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com