Automobile anticorrosive coating with self-recovery function and application thereof

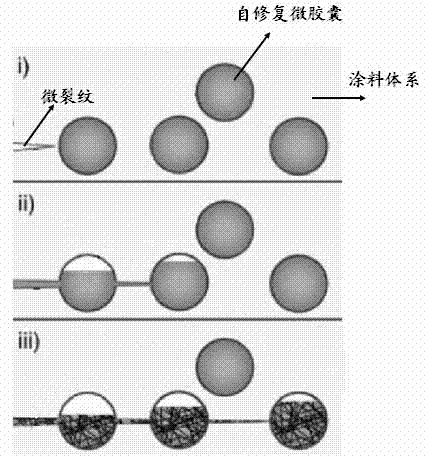

A self-healing and self-healing microcapsule technology, applied in anti-corrosion coatings, layered products, synthetic resin layered products, etc., can solve the problems of microcapsule rupture, instability, high price, etc. Integrity, the effect of increasing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

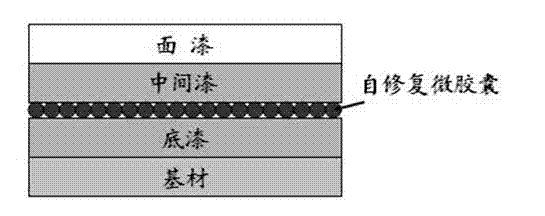

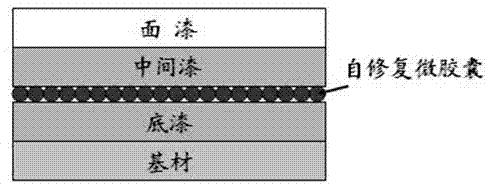

[0031] Spray a layer of phenolic resin primer (wet film thickness is about 150 μm) on the surface of the metal substrate with an air spray gun; self-healing microbes with a core material of tung oil, a core-to-wall ratio of 1:1, and an average particle size of 26.25 μm The capsules are evenly dispersed on the primer; after drying completely, use an air spray gun to spray a layer (wet film thickness of about 150 μm) of phenolic resin intermediate paint; after curing is complete, spray another layer (wet film thickness of about 150 μm) of amino Resin finish.

[0032] Among them, the phenolic resin primer is provided by Shanghai Zhenhua Paint Factory, model F01-2; the amino resin topcoat is provided by Shanghai Zhenhua Paint Factory, model A01-1.

[0033] Self-healing microcapsules were prepared as follows: Dissolve 0.78g of emulsifier OP-10 and 5 g of urea in 260 ml of deionized water; adjust the pH of the solution to 2.50 and acidify for 90 min; add 0.05 g of defoamer n-octanol...

Embodiment 2

[0035] Use an air spray gun to spray a layer of epoxy resin primer on the surface of the metal substrate (wet film thickness is about 200 μm); the core material is linseed oil, the core-to-wall ratio is 2:1, and the average particle size is 20.28 μm. The repair microcapsules are evenly dispersed on the primer; after drying completely, use an air spray gun to spray a layer of epoxy resin intermediate paint (wet film thickness is about 200 μm); after curing is complete, spray another layer (wet film thickness is about 200 μm) μm) acrylic topcoat.

[0036] Dissolve 0.97 g of emulsifier sodium dodecylbenzenesulfonate and 5 g of urea in 260 ml of deionized water; adjust the pH of the solution to 3.00 and acidify for 120 min; add 0.1 g of defoamer n-octanol; Under the condition of rpm, 19.38 g of linseed oil was added and emulsified for 30 min to form a stable emulsion; 4.69 g of formaldehyde was added under mechanical stirring at 70°C and reacted for 4 h; Capsule product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com