Environmentally-friendly treatment method and device for organosilicon slurry

An organic silicon slurry and environmental protection treatment technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of hydrogen chloride gas overflow, environmental pollution, etc., to facilitate recycling , the effect of solving environmental protection and safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

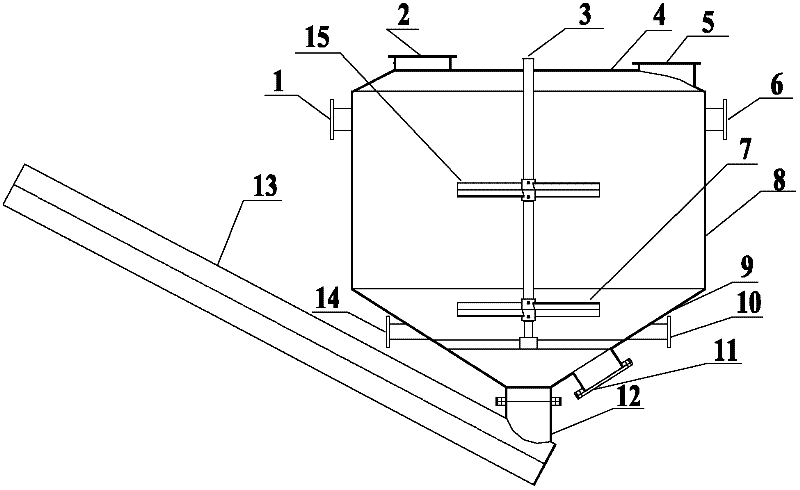

[0034] Embodiment 1, airtight hydrolysis tank

[0035] A kind of airtight hydrolysis tank, structure such as figure 1 As shown, the hydrolysis tank is equipped with an agitator, and the main part is the upper head 4 of the hydrolysis tank, the cylindrical body 8, the inverted cone body 9 and the hydrolyzate outlet 12 from top to bottom; the upper head 4 of the hydrolysis tank is provided with Slurry inlet 2 and spare gas suction port 5, two liquid overflow ports 1, 6 are symmetrically arranged on the upper part of the side wall of the cylindrical body 8, and two lye inlets 10, 6 are symmetrically arranged on the middle part of the side wall of the inverted cone body 9 14. One of the lye inlets 10 is provided with an emergency discharge port 11, and the middle of the bottom of the inverted cone body 9 is a granular hydrolyzate outlet 12, which is connected to a screw conveyor 13. The taper angle of the inverted cone cylinder is 50 degrees. The agitator is a double-blade agita...

Embodiment 2

[0038] A kind of environmental protection processing method of organic silicon slag, utilizes the equipment of above embodiment 1, and the steps are as follows:

[0039] The raw material slurry is a liquid-solid mixture with a solid content of 80wt%, which can flow under stirring and cool down to about 60°C;

[0040]Add 610kg of 10wt% sodium hydroxide solution in a closed hydrolysis tank with an agitator, and slowly add 500kg of raw material slurry into the closed hydrolysis tank within 30 minutes at 30°C, while the agitator stirs at a speed of 300 rpm, The slurry is hydrolyzed into granular hydrolyzate, which slides down from the side wall to the inlet of the screw conveyor at the bottom of the hydrolysis tank, and the screw conveyor separates the hydrolyzate to obtain a hydrolyzate with a wet weight of 750kg. The suspension of unreacted sodium hydroxide solution and copper hydroxide flows out from the upper overflow port of the airtight hydrolysis tank and enters the water s...

Embodiment 3

[0042] An environmentally friendly treatment method for organic silicon slag, the steps are as follows:

[0043] The liquid-solid mixture of the raw material slurry with a solid content of 50wt% is cooled to about 70°C;

[0044] Add 1200kg of 15wt% calcium hydroxide solution in the airtight hydrolysis tank with agitator, under 45 ℃ condition, in 40 minutes, slowly add 650kg slag slurry in the airtight hydrolysis tank, simultaneously agitator stirs with 160 rpm speed, slag The slurry is hydrolyzed into granular hydrolyzate, which slides down from the side wall to the inlet of the screw conveyor at the bottom of the hydrolysis tank, and the screw conveyor separates the hydrolyzate to obtain a hydrolyzate with a wet weight of 950kg. The unreacted calcium hydroxide solution and the suspension of copper hydroxide flow out from the upper overflow port of the airtight hydrolysis tank and enter the water storage tank, and are filtered by a filter press to reclaim 35kg of copper hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com