Method for synthesizing decyl acetal aldehyde

A technology for the synthesis of ten-carbon acetal and its synthesis method, which is applied in the field of synthesis of ten-carbon acetal, can solve the problems of numerous steps, high cost, and low yield, and achieve simple industrial operation, good industrialization prospects, and technical difficulty little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

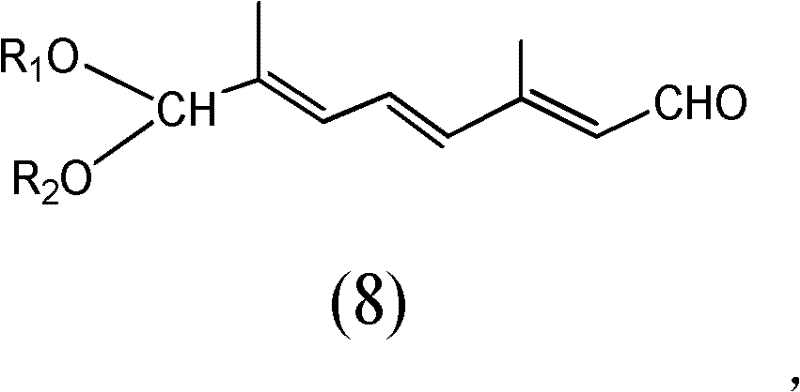

[0025] A kind of synthetic method of ten carbon acetals, comprises the following steps:

[0026] 1) Compound (E-4-acetoxy-2-methyl-2-butene-1-aldehyde) represented by structural formula (1) and trimethyl orthoformate or triethyl orthoformate at room temperature, acidic Carry out acetalization reaction under the effect of catalyzer p-toluenesulfonic acid, add alkali to carry out hydrolysis again after reaction finishes, obtain the acetal product as shown in structural formula (2),

[0027]

[0028] Among them, R 1 It is methyl or ethyl, and the molar ratio of the compound shown in structural formula (1), trimethyl orthoformate or triethyl orthoformate, and base is 1: 0.8-1.5: 0.6-1.2;

[0029] 2) the acetal product obtained in the previous step and the vinyl ether compound shown in (3) according to the molar ratio of 1: 0.8-1.2 at room temperature, catalyst (zinc chloride, zinc bromide, trichloride A kind of in iron) reacts under the effect, obtains the product of structur...

Embodiment 1

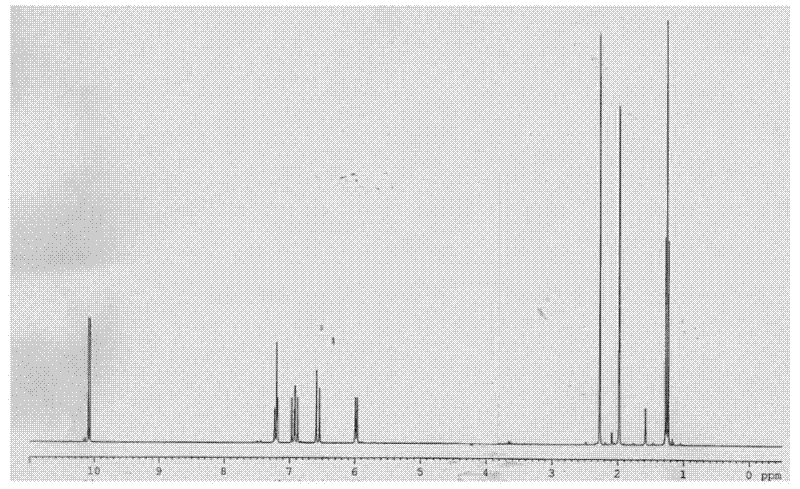

[0041] The preparation of the compound shown in structural formula as (8)

[0042]

[0043] Get 10 grams of the compound shown in structural formula (1), add catalytic amount of p-toluenesulfonic acid, add 10 grams of trimethyl orthoformate, react at room temperature for 10 hours, add 2 grams of hydrogen after the reaction finishes Sodium oxide, stirred and reacted for 6 hours, then added 200 milliliters of water, extracted three times with dichloromethane, 50 milliliters each time, combined the organic phases, backwashed the organic layer with 5% saline, 50 milliliters each time, dried with potassium carbonate, Filter, evaporate the solvent to dryness, and distill under reduced pressure to obtain 9 grams of the reaction product, the GC content is 98%, and the reaction equation is shown as follows:

[0044]

[0045]

Embodiment 2

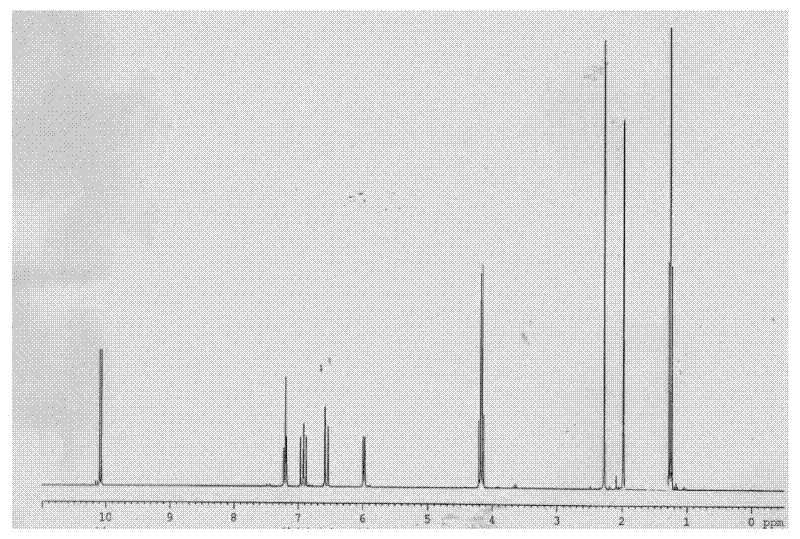

[0047] The preparation of the compound shown in structural formula as (9)

[0048]

[0049] Get 10 grams of the compound shown in structural formula (1), add catalytic amount of p-toluenesulfonic acid, add 11 grams of triethyl orthoformate, react at room temperature for 15 hours, add 2 grams of hydrogen after the reaction finishes Sodium oxide, stirred and reacted for 7 hours, then added 200 milliliters of water, extracted three times with dichloromethane, 50 milliliters each, combined the organic phases, backwashed the organic layer with 5% saline, 50 milliliters each, dried with potassium carbonate, Filter, evaporate the solvent to dryness, and distill under reduced pressure to obtain 10 grams of the reaction product, the GC content is 97%, and the reaction equation is shown as follows:

[0050]

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com