Method for preparing dipropyl carbonate through catalytic synthesis by using alkaline ionic liquid

A technology of dipropyl carbonate and basic ions is applied in the field of preparation of basic ionic liquid catalyzed synthesis of dipropyl carbonate, and can solve the problems of low catalyst efficiency, low yield of dipropyl carbonate, cumbersome recycling and the like, and achieves the The effect of reduced catalytic performance, good thermal stability, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

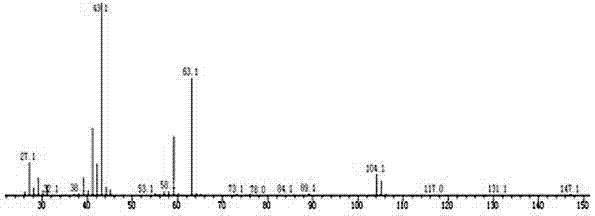

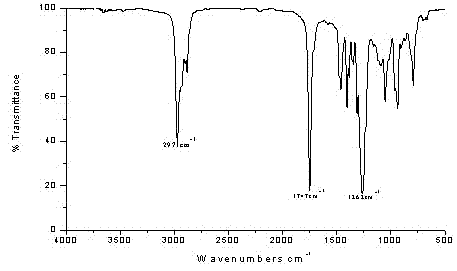

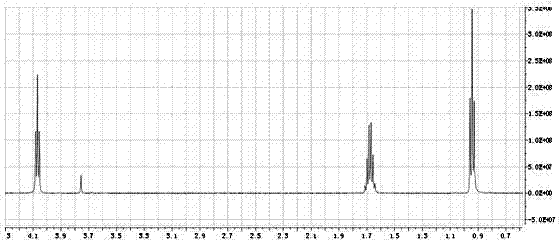

Image

Examples

Embodiment 1

[0030] A kind of preparation method of alkaline ionic liquid catalytic synthesis dipropyl carbonate, specifically comprises the following steps:

[0031] (1) In a 250mL four-neck flask equipped with a stirrer, a thermometer, a condenser, and a constant pressure dropping funnel, add 24g of n-propanol and 2% of the total mass of reactants 1-butyl-3-methyl hydroxide Imidazolium salt catalyst, heated to 90°C, slowly and uniformly added 9g of dimethyl carbonate dropwise, and transesterified for 1h;

[0032] (2) Connect the water separator to the device in step (1), raise the temperature to 100°C to evaporate the methanol generated by the reaction, continue the transesterification reaction for 3 hours, then cool to room temperature, control the vacuum degree to 20mmHg and carry out vacuum distillation for 20 After min, let stand and stratify;

[0033] (3), the upper layer liquid obtained after static layering in step (2) is then subjected to vacuum distillation, the vacuum degree o...

Embodiment 2

[0039] A kind of preparation method of alkaline ionic liquid catalytic synthesis dipropyl carbonate, specifically comprises the following steps:

[0040] (1) In a 250mL four-neck flask equipped with a stirrer, a thermometer, a condenser, and a constant pressure dropping funnel, add 24g of n-propanol and 2% of the total mass of reactants 1-butyl-3-methyl hydroxide Imidazolium salt catalyst, heated to 90°C, slowly and uniformly added 9g of dimethyl carbonate dropwise, and transesterified for 1h;

[0041](2) Connect the water separator to the device in step (1), raise the temperature to 100°C to evaporate the methanol generated by the reaction, continue the transesterification reaction for 4 hours, then cool to room temperature, control the vacuum degree to 20mmHg and carry out vacuum distillation for 20 minutes After that, let stand to stratify;

[0042] (3), the upper layer liquid obtained after static layering in step (2) is then subjected to vacuum distillation, the vacuum d...

Embodiment 3

[0045] A kind of preparation method of alkaline ionic liquid catalytic synthesis dipropyl carbonate, specifically comprises the following steps:

[0046] (1) In a 250mL four-neck flask equipped with a stirrer, a thermometer, a condenser, and a constant pressure dropping funnel, add 24g of n-propanol and 3% of the total mass of reactants 1-butyl-3-methyl hydroxide Imidazolium salt catalyst, heated to 90°C, slowly and uniformly added 9g of dimethyl carbonate dropwise, and transesterified for 1h;

[0047] (2) Connect the water separator to the device in step (1), raise the temperature to 100°C to evaporate the methanol generated by the reaction, continue the transesterification reaction for 4 hours, then cool to room temperature, control the vacuum degree to 20mmHg and carry out vacuum distillation for 30 After min, let stand and stratify;

[0048] (3), step (2) The upper layer liquid obtained after the static layering is then subjected to vacuum distillation, the vacuum distill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com