MDI-TMP (diphenyl-methane-diisocyanate-trimethylolpropane) type polyurethane prepolymer with high end-capping rate

A polyurethane prepolymer, end-capping rate technology, applied in the field of chemistry, can solve problems such as low end-capping rate, and achieve the effects of reducing damage, improving end-capping rate, and reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Add 15 parts of ethyl acetate to a reaction kettle filled with nitrogen, then add 30 parts of MDI, raise the temperature to 50°C, stir at the same time until it is completely dissolved, add 15 parts of TMP, and raise the temperature to 70°C, the reaction 4 hours, then add 30 parts of sodium bisulfite, 10 parts of sodium sulfite, and react for 2 hours; finally add a small amount of phosphoric acid to adjust the pH to 4.5.

[0015] After testing, the technical indicators of the obtained MDI-TMP bridging agent are as follows: the appearance is a water-white transparent liquid at room temperature, the solid content is 56%, the viscosity is 1304mPa. s, the -NCO content is 11.0~11.5%, free TDI monomer The content is less than 0.05%; the end-capping rate of the polyurethane product is greater than 90% as determined by iodine molecular titration.

Embodiment 2~3

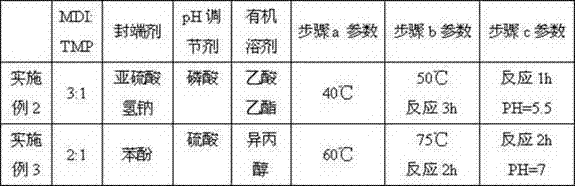

[0017] The preparation process steps of Examples 2-3 are the same as those of Examples, except that the ratio of MDI to TMP added, end-capping agent, pH regulator and reaction parameters are different. Table 1 is the ratio of MDI and TMP added in Examples 2 to 3, end-capping agent, pH regulator and reaction parameters.

[0018]

[0019] Embodiment 2 and 3, what adopt all is sodium sulfite, and the capping rate of tested polyurethane product is also greater than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com