Polyurethane putty for concrete surface treatment

A polyurethane putty, low surface tension technology, applied in the direction of filling slurry, etc., can solve the problems of construction efficiency limitation and incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

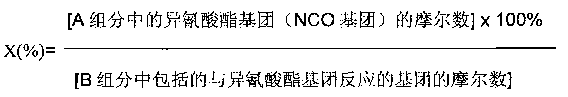

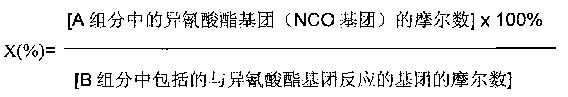

Method used

Image

Examples

Embodiment 1

[0060] Example 1 B component preparation method

[0061] Take 30 parts of N210 polyether polyol, 13 parts of Stepanpol PD-110LV polyester polyol, and 7 parts of N303 polyether polyol, mix the above polyols in the reactor and then raise the temperature to 110°C, then lower the temperature to -0.02mPa. Dehydrate under vacuum conditions for 2 hours, and control the moisture content below 0.005%.

[0062] Take 44 parts of commercially available 600-mesh talcum powder, dry at 400°C for 5 hours, add 6 parts of polyamide wax (Bentone EW) after cooling down to room temperature, and then knead in a kneader together with the aforementioned dehydrated polyol mixture After 1 hour, ensure that the mixture is uniform, and then use a three-roller grinder to grind the material until it becomes a fine and uniform white paste, and then the B component is obtained.

Embodiment 2

[0063] Embodiment 2 B component preparation method

[0064] Take 40 parts of N220 polyether polyol, 10 parts of Stepanpol PD-200LV polyester polyol, 10 parts of 1,4-butanediol, mix the above-mentioned polyols in the reactor and raise the temperature to 110°C. Dehydration under mPa. vacuum condition for 2 hours, control the moisture content below 0.005%.

[0065] Take 30 parts of commercially available 700-mesh kaolin, dry at 400°C for 5 hours, then add 10 parts of polyamide wax (Disparlon 6900-20X) after cooling down to room temperature, and then add it to the kneader together with the aforementioned dehydrated polyol mixture Knead for 1 hour to ensure uniform mixing, and then use a three-roller grinder to grind until a fine and uniform white paste material is obtained, and then component B is obtained.

Embodiment 3

[0066] Embodiment 3 B component preparation method

[0067] Take 35 parts of PEBA-1500 polyester polyol, 10 parts of Stepanpol PD-200LV polyester polyol, and 5 parts of diethylene glycol, mix the above polyols in the reactor and heat up to 110°C, then lower the temperature to -0.02mPa. Dehydrate under vacuum conditions for 2 hours, and control the moisture content below 0.005%.

[0068] Take 15 parts of commercially available 700 mesh talcum powder and 21 parts of kaolin, dry at 400°C for 5 hours, then add 14 parts of polyamide wax (Bentone EW) after cooling down to room temperature, and then add it together with the aforementioned dehydrated polyol mixture Add to a kneader and knead for 1 hour to ensure uniform mixing, and then use a three-roll mill to grind until a fine and uniform white paste material is obtained, and then component B is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com