Middle-sized aluminum mill ball and preparation method

A technology of grinding balls and aluminum, applied in chemical instruments and methods, and other chemical processes, can solve problems such as unsatisfactory performance and single use, reduce production costs and labor intensity, simple molding process, and reasonable formula Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

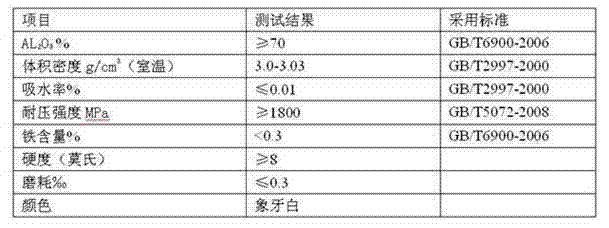

Examples

Embodiment 1

[0020] Embodiment 1: A kind of aluminum grinding ball and its preparation method

[0021] 1. Composition of raw materials: expressed in weight percentage, cooked bauxite 88%, dolomite 4%, porcelain stone 4%, clay 3%, sodium humate 1%. The cooked bauxite includes three types of cooked bauxite with aluminum contents of 72-73%, 74-75%, and 77-78%, and their weight ratios are 34%, 21% and 33% respectively.

[0022] Raw material performance requirements:

[0023] Dolomite: MgO+CaO>38%, China stone: Na content>7%, clay: aluminum content>20%.

[0024] 2. The preparation method comprises the following steps:

[0025] (1) Grinding: weigh according to the composition of the raw materials, crush the bulk raw materials to particles below 3mm, add them to the ball mill, add water according to the weight ratio of raw materials and water at a weight ratio of 7:3, and add 3-5‰ of the total amount of raw materials to disperse Sodium tripolyphosphate, 3-5‰ of polyvinyl alcohol solution, grin...

Embodiment 2

[0029] Embodiment 2: Aluminum grinding ball and preparation method thereof are basically the same as Example 1, the difference being:

[0030] Raw materials of Chalco grinding balls: 88% cooked bauxite, 3% dolomite, 4% porcelain stone, 3% clay, and 2% sodium humate. The cooked bauxite includes three types of cooked bauxite with aluminum content of 72%, 74% and 77%, and their weight ratios are 34%, 21% and 33% respectively.

Embodiment 3

[0031] Embodiment 3: Aluminum grinding ball and preparation method thereof are basically the same as Example 1, except that:

[0032] Raw materials of Chalco grinding balls: 88% cooked bauxite, 5% dolomite, 2% porcelain stone, 4% clay, and 1% sodium humate. The cooked bauxite includes three types of cooked bauxite with an aluminum content of 73%, 75% and 77%, and their weight ratios are 34%, 21% and 33% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com