Simulation method of electro-spinning fiber closed-ring control based on finite element and system discrimination

A system identification and closed-loop control technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of difficult control of fiber diameter and poor real-time response of fiber diameter, and achieve the effect of eliminating limitations and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

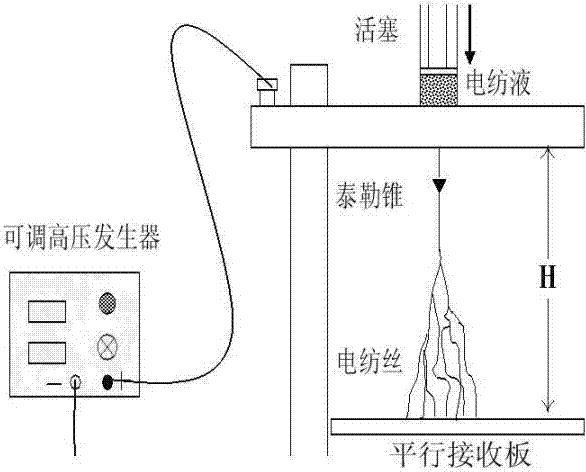

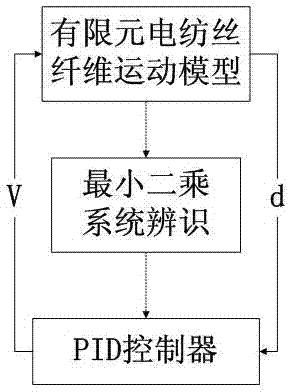

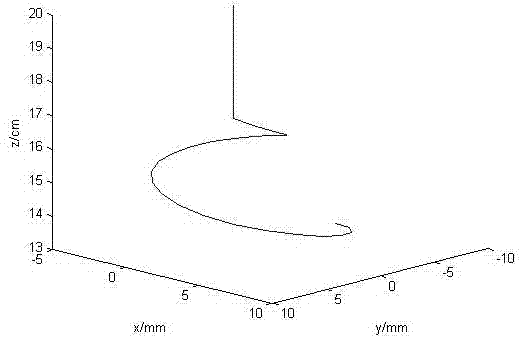

[0046] Such as figure 1 As shown, an electrospinning fiber manufacturing equipment includes an adjustable high-voltage generator, an electrospinning liquid propulsion piston, parallel receiving plates, and the distance between the receiving plates is H. The electrospinning first brings the polymer solution or melt to several thousand With tens of thousands of volts of high-voltage static electricity, the charged polymer electrospun droplets are accelerated at the apex of the Taylor cone of the capillary under the action of the electric field force. When the electric field force is strong enough, the polymer electrospun droplet overcomes the surface tension to form a jet stream. The thin stream evaporates or solidifies the solvent during the spraying process, and finally falls on the receiving device, forming a fibrous mat like a nonwoven cloth. In the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com