Multilayer organic solar cell using a polyelectrolyte layer, and method for manufacturing same

A technology for solar cells and a manufacturing method, applied in the field of solar cells, can solve problems such as application of polymers, and achieve the effects of simple manufacturing process, omitting heat treatment process, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0020] The present invention allows various modifications and various embodiments, and specific examples will be illustrated and described below. However, this is not intended to limit the specific disclosure, and it should be understood that various changes and equivalent substitutions can be made without departing from the principle of the present invention and the invention in the technical field. During the description with reference to the drawings, like reference numerals will be used for like structural components.

[0021] Hereinafter, embodiments of the present invention will be described in more detail with reference to the accompanying drawings.

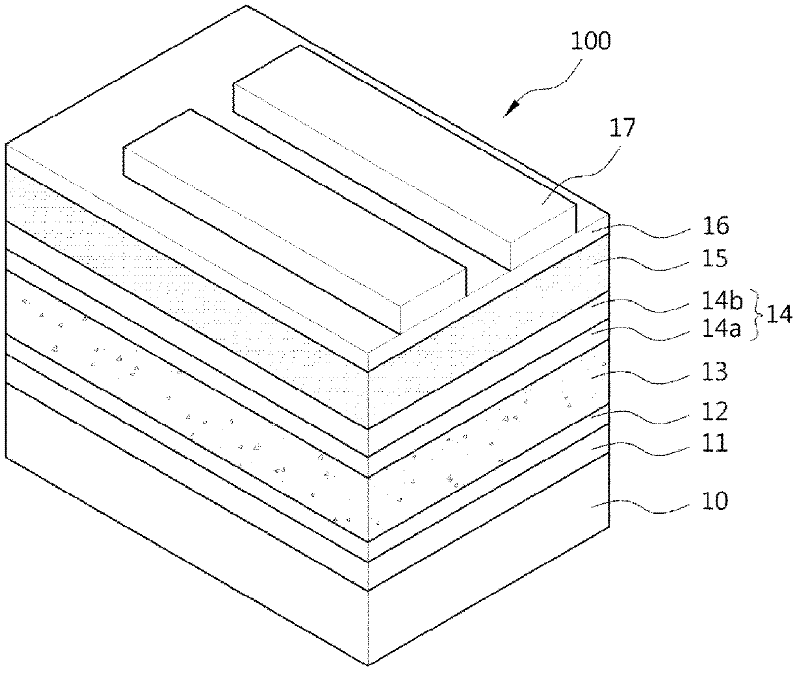

[0022] figure 1 It is a schematic diagram of a laminated organic solar cell 100 according to an embodiment of the present invention.

[0023] refer to figure 1 On the substrate 10, the first electrode 11, the first charge transport layer 12, the first organic photoactive layer 13, the composite layer 14, the second orga...

manufacture example 1

[0065] Production Example 1: Production of laminated organic solar cells

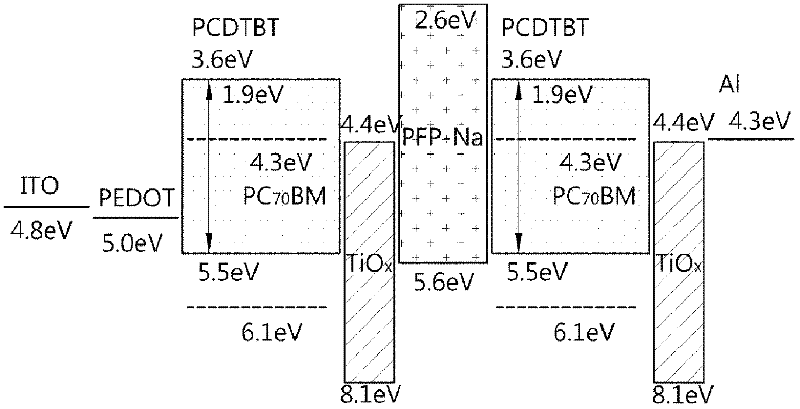

[0066] Provided is a substrate in which an ITO layer as a first electrode is coated on a glass substrate. PEDOT:PSS was coated as a first charge transport layer on the above-mentioned ITO layer in a thickness of 30 nm. PCDTBT as electron donor and PC as electron acceptor 70 BM is put into dichlorobenzene and mixed to make PCDTBT: PC 70 After the BM solution, the above-mentioned PCDTBT:PC 70 BM solution to form the first organic photoactive layer.

[0067] After the titanium precursor sol was prepared using titanium tetraisopropoxide (Titanium (IV) isopropanol), 2-ethylene glycol monomethyl ether (2-methoxyethanol) and ethanolamine (ethanolamine) under a nitrogen atmosphere, the spin coating method was used to The titanium precursor sol is coated on the above-mentioned first organic photoactive layer. The coated titanium precursor sol forms a titanium oxide film, that is, an n-type semiconductor m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com